Preparation method of environment-friendly flame retardant flame-retardant rubber

A technology of flame retardant rubber and intumescent flame retardant, which is applied in the field of preparation of flame retardants. It can solve the problems of poor dispersibility, large addition amount, and poor thermal stability of the charcoal layer, so as to improve poor dispersibility and enhance charcoal forming ability. , Improve the effect of grafting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

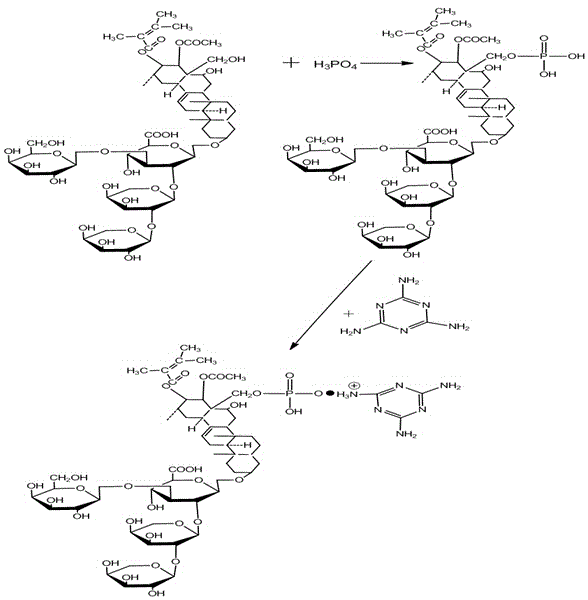

[0021] Add 40 g of phosphoric acid and 7 g of tea saponin into the reaction vessel in batches, and stir under reflux in a water bath at 50° C. for 4 hours. Vacuum filtration at 50°C to extract the water generated during the reaction. The obtained product, 10 g of melamine and 100 ml of absolute ethanol solution were stirred at room temperature for 3 hours. The tea saponin-based "trinity" intumescent flame retardant was prepared by reaction.

[0022] Ultrasonic disperse 0.16g graphene in 150ml distilled water, prepare 10mmol / 5mmol EDC / NHS aqueous solution and add it to the dispersed graphene, stir at room temperature for 0.5 hours, add tea saponin-based "Trinity" intumescent flame retardant and stir at room temperature After 4 hours, the tea saponin-based "trinity" intumescent flame retardant functionalized graphene was prepared.

[0023] 100 parts of natural rubber; 1.2 parts of sulfur; 0.8 parts of accelerator CZ; 0.35 parts of accelerator TMTD; 4 parts of stearic acid;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com