Technological method for preparing polysilicon by silane method

A process method, polysilicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of reducing product yield and product quality, high single-pass conversion rate, fast homogeneous decomposition rate of silane, etc. Yield and quality, the effect of reducing the generation of silicon powder, and reducing the temperature of the gas phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

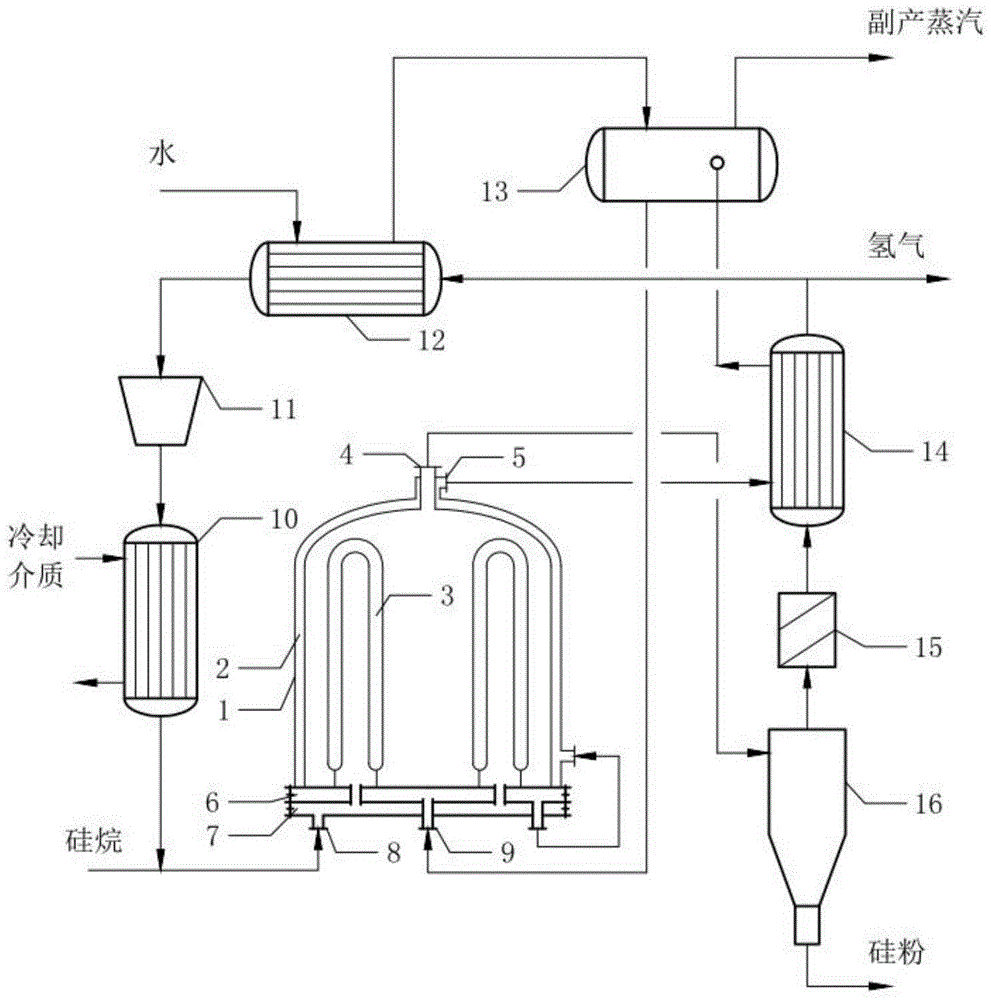

[0018] Such as figure 1 As shown, a process method for preparing polysilicon by a silane method, the process equipment involved in the process method includes a reduction furnace 1, a cyclone separator 16, a filter 15, a waste heat exchanger 14, a steam drum 13, a water cooler 12, Circulating hydrogen compressor 11, cryogenic cooler 10 and connecting pipelines. Wherein the reduction furnace is a place where the chemical vapor deposition reaction occurs, including a bell jar cooling jacket 2 , a chassis cooling jacket 6 , silicon rods 3 and a gas chamber 7 . Described processing method specifically comprises the following steps:

[0019] (1) Silane / hydrogen mixture, wherein the volume fraction of the silane is 2%, enters the reduction furnace 1 through the gas chamber 7, the internal pressure of the reduction furnace 1 is 6MPaG, and the silicon rod 3 is heated by electrodes method, the surface temperature of the silicon rod is controlled at 900°C, the silane undergoes a heter...

Embodiment 2

[0027] The difference from Example 1 is that by increasing the cooling water flow rate, the temperature of the bottom plate and the inner wall of the bell jar of the reduction furnace 1 is maintained at 400° C., which can further reduce the deposition of elemental silicon on the bottom plate and the inner wall of the bell jar. The temperature of the reduction tail gas drops to 110°C after heat exchange through the waste heat heat exchanger 14, and the temperature of the circulating hydrogen drops to 40°C after heat exchange through the water cooler 12, and after being compressed, the temperature drops to 40°C in the low temperature cooler 10 The intermediate cooling medium is further cooled to -20°C, thereby further reducing the gas phase temperature in the reduction furnace 1, reducing the homogeneous cracking reaction rate of silane, reducing the generation of silicon powder, and improving the yield and quality of polysilicon products.

Embodiment 3

[0029] Different from Example 1, by adjusting the electrode heating rate and controlling the surface temperature of the silicon rod 3 at 800°C, the gas phase temperature in the reduction furnace 1 can be lowered, thereby reducing the homogeneous cracking reaction rate of silane and reducing silicon Powder generation, improve the yield and quality of polysilicon products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com