Amorphous calcium carbonate nanosheet material and preparation method thereof

A calcium carbonate and nanosheet technology, applied in the field of nanomaterials, can solve the problems of harsh and complex experimental conditions, and achieve the effects of easy mass production, simple and easy-to-obtain template materials, and simple and controllable preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

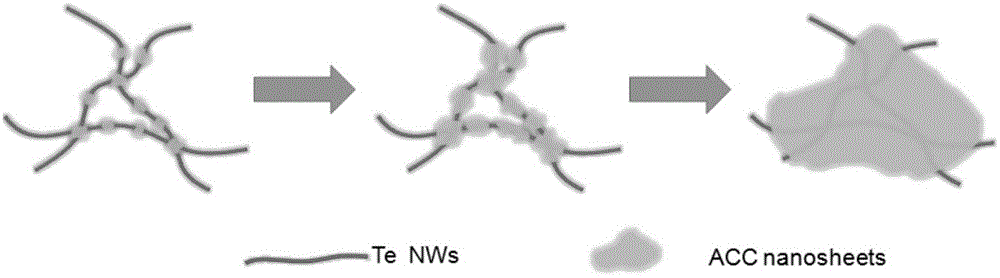

[0035] The present invention provides a kind of preparation method of amorphous calcium carbonate nano sheet material, comprising:

[0036] 1) washing the tellurium nanowires to obtain the washed tellurium nanowires,

[0037] The zeta potential of the washed tellurium nanowires is less than or equal to -14mV;

[0038] 2) mixing the washed tellurium nanowires with the first solvent to obtain a tellurium nanowire solution,

[0039] The volume ratio of the tellurium nanowires to the first solvent is (0.2-10):1;

[0040] 3) reacting the tellurium nanowire solution, the calcium source and the carbon source to obtain the amorphous calcium carbonate nanosheet material.

[0041] According to the present invention, the present invention first washes the tellurium nanowires to obtain the washed tellurium nanowires; wherein, the diameter of the tellurium nanowires is 1 nm to 50 nm, more preferably 5 nm to 40 nm, most preferably 7 nm to 35 nm, most preferably Preferably 10nm-30nm; the ...

Embodiment 1

[0058] 1) Synthesis of tellurium nanowires

[0059] Weigh 2g of polyvinylpyrrolidone and dissolve it in 66mL of deionized water in 100mL of polytetrafluoroethylene lining, weigh 0.1846g of sodium tellurite and add it to the polytetrafluoroethylene lining, and stir until the solution is clear. Then add 6.7mL of ammonia deionized water (mass fraction 25-28%) and 3.3mL hydrazine hydrate (mass fraction 85%), stir for 3h until uniform, react in a closed reaction vessel at 180°C for 3 hours, cool naturally for later use, and obtain Precipitated 7nm tellurium nanowires;

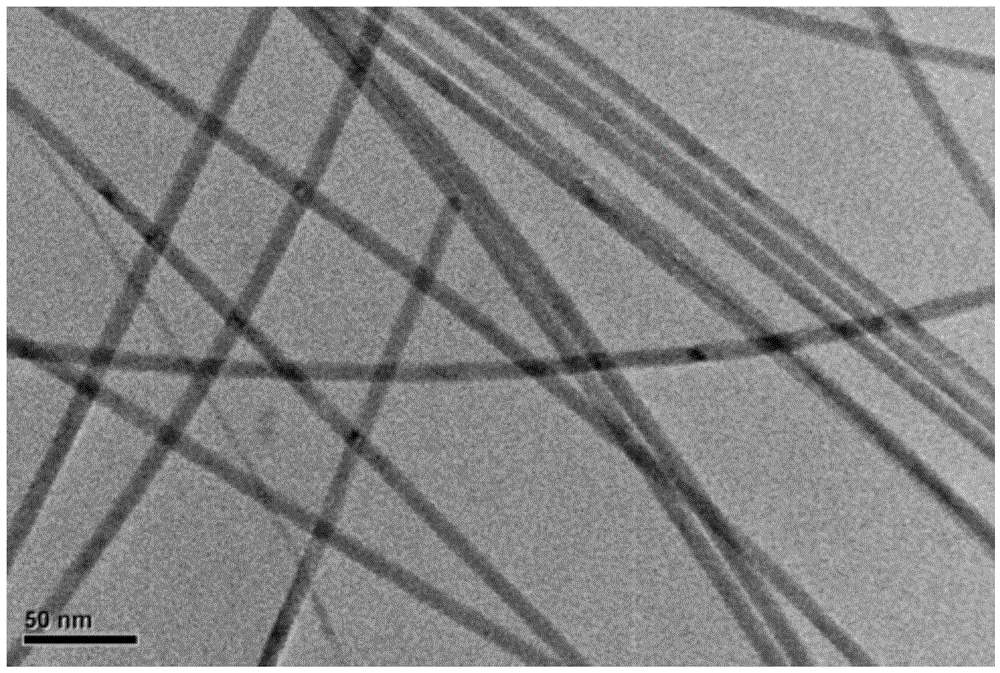

[0060] Observation of Te nanowires precipitated by parasite, the results are shown in figure 2 , figure 2 TEM pictures of unprecipitated 7nm tellurium nanowires provided for the embodiments of the present invention;

[0061] 2) Precipitation of tellurium nanowires

[0062] Add 15mL of acetone to 4mL of unprecipitated 7nm tellurium nanowires. After about 10min, the tellurium nanowires gather at the bottom of th...

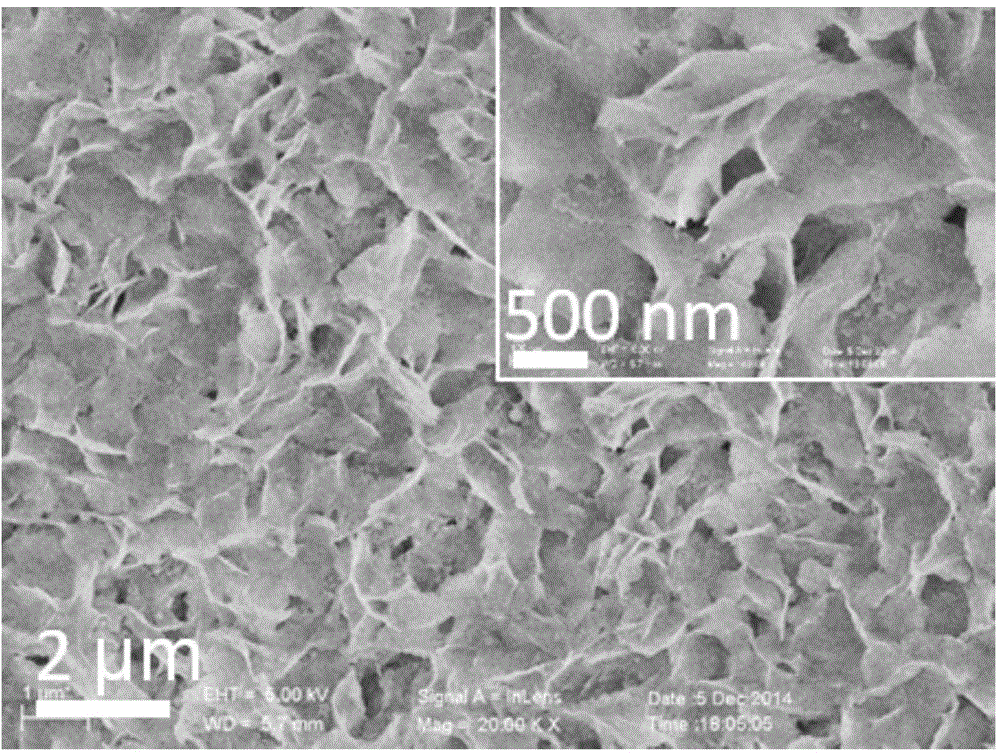

Embodiment 2

[0078] 1) Synthesis of tellurium nanowires

[0079] Weigh 2g of polyvinylpyrrolidone and dissolve it in 66mL of deionized water in 100mL of polytetrafluoroethylene lining, weigh 0.1846g of sodium tellurite and add it to the polytetrafluoroethylene lining, and stir until the solution is clear. Then add 6.7mL of ammonia water (mass fraction 25-28%) and 3.3mL of hydrazine hydrate (mass fraction 85%), stir for 3 hours until uniform, and react in a closed reaction vessel at 180°C for 3 hours, cool naturally for use, and obtain unprecipitated 7nm Tellurium nanowires;

[0080] 2) Precipitation of tellurium nanowires

[0081] Add 6mL of acetone to 1.5mL of unprecipitated 7nm tellurium nanowires. After about 10min, the tellurium nanowires are aggregated at the bottom of the beaker. Take out the black agglomerates and transfer them to a 50mL centrifuge tube at a speed of 8000rpm, centrifuge for 3min, wash with deionized water 3 times, ethanol Washing 3 times to obtain tellurium nanowi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| zeta potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com