Catalytic ozonation process for treatment of organic wastewater

A technology of ozone catalytic oxidation and organic wastewater, which is applied in the fields of oxidized water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of high generation rate of hydroxyl radicals, improved effective utilization, and increased contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment.

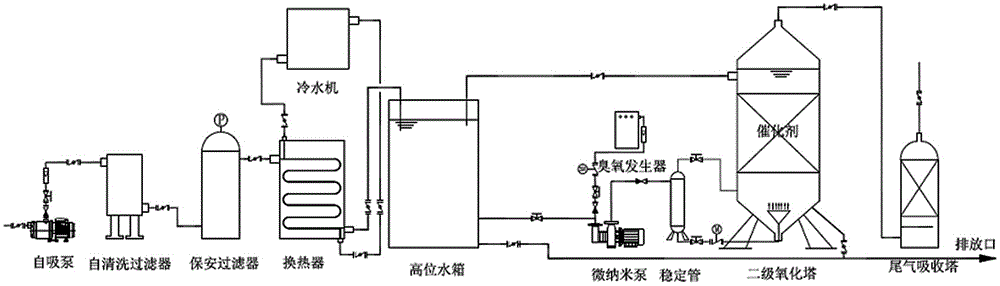

[0025] Such as figure 1 Shown, the step of organic wastewater ozone catalytic oxidation treatment process of the present invention comprises:

[0026] 1. Lift the pretreated organic wastewater into the self-cleaning filter through the self-priming pump. In the self-cleaning filter, most of the larger suspended solids in the wastewater are removed, and the produced water after the self-cleaning filter enters the security filter , to further remove suspended solids and colloidal substances in water;

[0027] 2. In step 1, the water produced by the security filter enters the heat exchanger of the cooling system and exchanges heat with the circulating cooling water of the cooling system. The water temperature of the waste water is reduced to about 25°C, and the cooling water is cooled by the chiller of the cooling system. Recycling below 25°C;

[0028] 3. The waste water heated up by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com