High-concentration low-temperature-resistant liquid phosphorus-potassium fertilizer and preparation method thereof

A low-temperature-resistant, high-concentration technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems that unqualified enterprises cannot purchase and use fertilizers, fertilizers cannot be used on chlorine-resistant crops, and unfavorable product production, etc., to increase the slow-release effect, The effect of improving farmers' labor efficiency and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

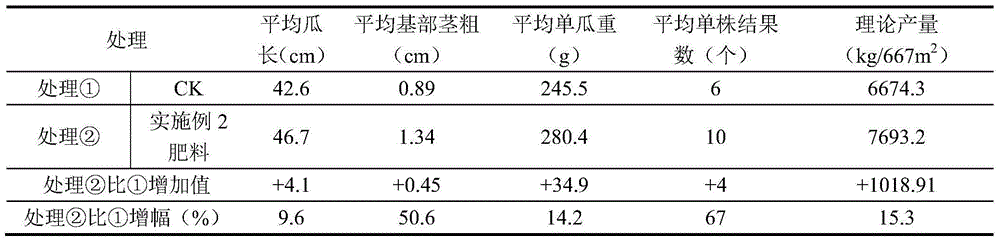

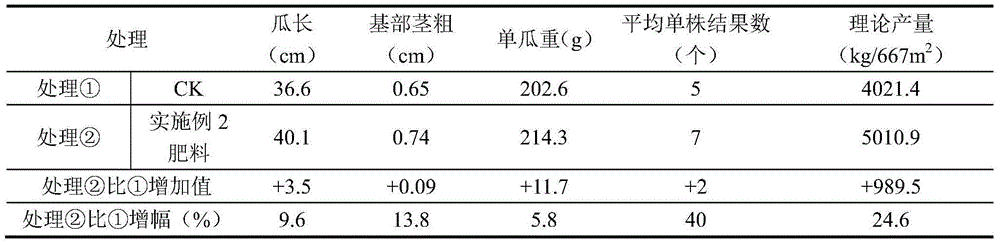

Examples

Embodiment 1

[0024] (1) Add 400kg of pure water to the enamel reaction kettle, turn on the stirring and condensing circulating water, slowly add 435kg of potassium tripolyphosphate into it, control the temperature in the kettle at 30°C and stir at a constant speed for 2h.

[0025] (2) Then lower the temperature to 5°C, slowly add 510kg of potassium hydroxide, and stir for 2 hours until fully dissolved.

[0026] (3) Keep the temperature at 10°C, add 350kg of citric acid to adjust the pH value of the solution, control the temperature in the kettle at 30°C, and stir for 1 hour.

[0027] (4) Add sodium octaborate tetrahydrate and stir until dissolved, which takes 30 minutes.

[0028] (5) Add EDTA-Zn and stir until dissolved, which takes 30 minutes, and cool to room temperature to obtain liquid phosphorus and potassium fertilizer.

[0029] (6) Antifreeze synergist configuration: open the small stirrer of the reaction kettle, add 2kg of triethanolamine and stir, add 2kg of phytic acid and stir ...

Embodiment 2

[0032] (1) Add 450kg of pure water to the enamel reaction kettle, turn on the stirring and condensing circulating water, slowly add 400kg of potassium tripolyphosphate to it, control the temperature in the kettle at 50°C and stir at a constant speed for 2 hours.

[0033] (2) The temperature in the kettle was controlled at 50°C, and 332g of potassium formate was added slowly, and stirred for 30min until the solution was clear and uniform.

[0034] (3) Then lower the temperature to 10°C, slowly add 400kg of potassium pyrophosphate, and stir at a constant speed for 1 hour until fully dissolved.

[0035] (4) Keep the temperature at 20° C., add 80 kg of phosphoric acid (85%) to adjust the pH value of the solution, control the temperature in the kettle at 50° C., and stir at an even speed for 1 hour.

[0036] (5) Add sodium octaborate tetrahydrate and stir until dissolved, which takes 30 minutes.

[0037] (6) Add EDTA-Zn and stir until dissolved, it takes 30min, then cool to room tem...

Embodiment 3

[0041] (1) Add 500kg of pure water to the enamel reaction kettle, turn on the stirring and condensing circulating water, slowly add 400kg of potassium tripolyphosphate to it, control the temperature in the kettle at 45°C and stir at a constant speed for 2 hours.

[0042] (2) The temperature in the kettle was controlled at 45°C, and 220kg of potassium hydroxide (mass fraction 85%) and 150kg of potassium formate were slowly added, and stirred for 35min until the solution was clear and homogeneous.

[0043] (3) Then lower the temperature to 8°C, slowly add 150kg of potassium pyrophosphate, and stir at a uniform speed for 1 hour until fully dissolved.

[0044] (4) Keep the temperature at 15°C, add 200kg of phosphoric acid (mass fraction 85%) and 40kg of citric acid to adjust the pH value of the solution, control the temperature in the kettle at 35°C, and stir at a constant speed for 1h.

[0045] Add 20 kg of sodium octaborate tetrahydrate and stir until dissolved, which takes 30 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com