Technique for preparing oxalic acid by performing continuous reaction rectification hydrolysis on dimethyl oxalate

A technology for dissolving dimethyl oxalate and dimethyl oxalate, which is applied in the preparation of carboxylate/lactone, sustainable manufacturing/processing, separation/purification of carboxylic acid compounds, etc. Dimethyl oxalate is easy to block and other problems, to achieve the effect of improving hydrolysis conversion rate, reducing equipment investment and improving environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

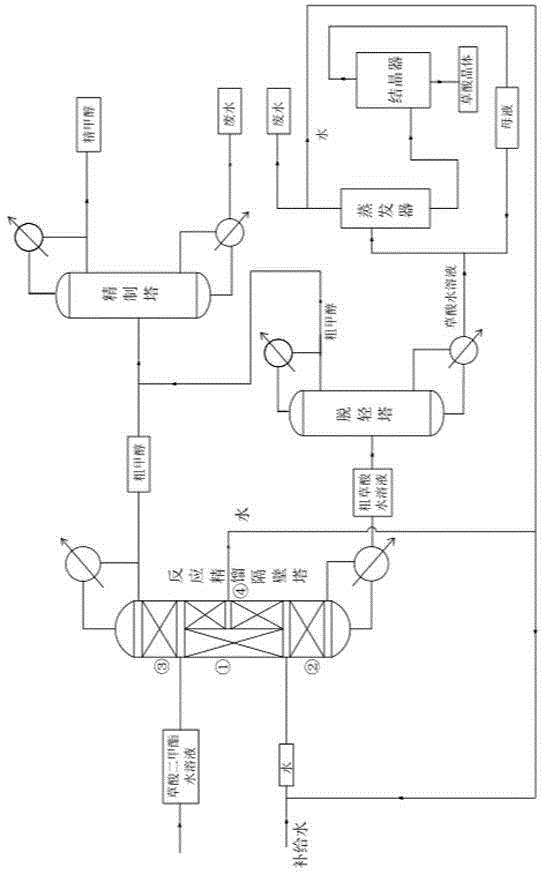

Embodiment 1

[0022] Dimethyl oxalate is dissolved in hot water at 65°C, the molar ratio of water to ester is 4:1, and it is fed from the upper feed port at a feed rate of 1.91g / min. The reactive distillation dividing wall column is a packed column, and the rectification section The number of theoretical plates is 6, and the reaction section and sideline production section The number of theoretical plates is 20, and the stripping section The number of theoretical plates is 3, and the reflux ratio is 2; the lower feed port is fed with water at normal temperature, the feed rate is 1.09g / min, and the total molar ratio of water to ester is 12. Crude methanol is extracted from the top of the reactive distillation dividing wall column at a recovery rate of 0.36g / min, and an aqueous oxalic acid solution containing a small amount of methanol is extracted from the bottom of the reactive distillation dividing wall column at a recovery rate of 2.70g / min. Produced water in the production section...

Embodiment 2

[0024] Dimethyl oxalate is dissolved in hot water at 65°C, the molar ratio of water to ester is 4:1, and it is fed from the upper feed port at a feed rate of 1.91g / min. The reactive distillation dividing wall column is a packed column, the number of theoretical plates in the rectification section ③ is 6, the number of theoretical plates in the reaction section ① and the sideline extraction section ④ is 20, and the number of theoretical plates in the stripping section ② is 3 blocks, the reflux ratio is 2; the lower feed port is fed with water at room temperature, the feed rate is 1.09g / min, and the total molar ratio of water to ester is 15. Crude methanol is extracted from the top of the reactive distillation dividing wall column at a recovery rate of 0.36g / min, and an aqueous oxalic acid solution containing a small amount of methanol is extracted from the bottom of the reactive distillation dividing wall column at a recovery rate of 2.70g / min. Produced water in the production ...

Embodiment 3

[0026] Dimethyl oxalate is dissolved in hot water at 65°C, the molar ratio of water to ester is 4:1, and it is fed from the upper feed port at a feed rate of 1.91g / min. The reactive distillation dividing wall column is a packed column, the number of theoretical plates in the rectification section ③ is 6, the number of theoretical plates in the reaction section ① and the sideline extraction section ④ is 20, and the number of theoretical plates in the stripping section ② is 3 blocks, the reflux ratio is 4; the lower feed port feeds water at room temperature, the feed rate is 1.09g / min, and the total molar ratio of water to ester is 15. Crude methanol is extracted from the top of the reactive distillation dividing wall column at a recovery rate of 0.36g / min, and an aqueous oxalic acid solution containing a small amount of methanol is extracted from the bottom of the reactive distillation dividing wall column at a recovery rate of 2.70g / min. Produced water in the production sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com