Synthesis and purification method for alpha-amino acid compound

An amino acid and purification method technology, which is applied in the field of synthesis and purification of α-amino acid compounds, can solve problems such as difficulty in separation, and achieve the effects of high purity, recycling and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

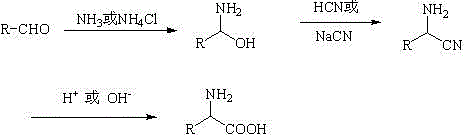

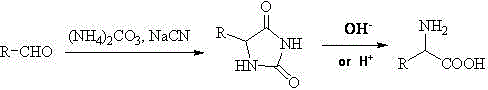

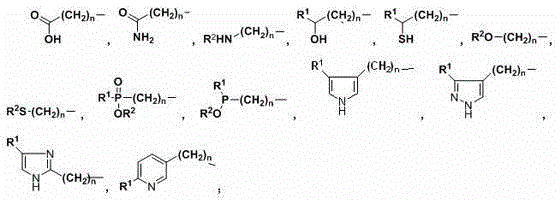

Method used

Image

Examples

Embodiment example 1

[0061] Example 1: Synthesis of 2-amino-4-methylthiobutyric acid

[0062] Add 130g (1mol) of 2-amino-4-methylthiobutyronitrile into a 1L autoclave, add 68g of 25% ammonia water and 56g (1mol) of calcium oxide, 2g of tetrabutylammonium bisulfate, 500g of water, and heat to 180-190 o C, pressure 2.5-3.0MPa, react for 5h, cool down to room temperature, pass carbon dioxide under stirring until pH = 8, filter, concentrate the mother liquor under reduced pressure, add 150g methanol to the residue and reflux for 2h, cool down, and crystals precipitate out. Filtration, vacuum 120 o C dried for 4 hours to obtain 118.3 g of 2-amino-4-methylthiobutyric acid with a purity of 96% and a yield of 79.4%.

Embodiment example 2

[0063] Example 2: Synthesis of 2-amino-3-(4-imidazolyl)propionic acid

[0064] Add 180g (1mol) of 5-[(4-imidazolyl)methyl]hydantoin to a 1L autoclave, add 68g of 25% ammonia water and 110g (1.5mol) of calcium hydroxide, 500g of water, and heat to 160-170 o C, pressure 1.5~2.0MPa, react for 8h, cool down to room temperature, pass carbon dioxide under stirring until pH=8, filter, concentrate the mother liquor under reduced pressure, add 150g methanol to the residue and reflux for 2h, cool down, and crystals precipitate out. Filtration, vacuum 120 o C dried for 4 hours to obtain 124.2 g of 2-amino-3-(4-imidazolyl)propionic acid with a purity of 96% and a yield of 80.1%.

Embodiment example 3

[0065] Example 3: Synthesis of 2-amino-3-(4-imidazolyl)propionic acid

[0066] Add 180g (1mol) of 5-[(4-imidazolyl)methyl]hydantoin to a 1L autoclave, add 68g of 25% ammonia water and 110g (1.5mol) of calcium hydroxide, 3g of triethylbenzyl ammonium sulfate, and 500g of water , heated to 160-170 o C, pressure 1.5~2.0MPa, react for 3h, cool down to room temperature, pass carbon dioxide to pH=8, filter, concentrate the mother liquor under reduced pressure, add 150g methanol to the residue and reflux for 2h, cool down, and crystals precipitate out. Filtration, vacuum 120 o C dried for 4 hours to obtain 134.5 g of 2-amino-3-(4-imidazolyl)propionic acid with a purity of 96% and a yield of 86.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com