Preparation method of polyacrylic acid hollow microgel

A technology of polyacrylic acid and microgel, which is applied in the field of preparation of polyacrylic acid hollow microgel to achieve good emulsification stability, easy implementation, and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

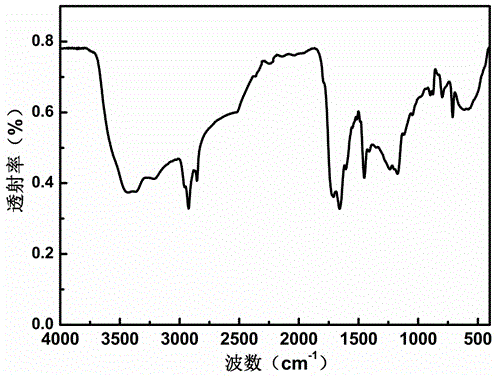

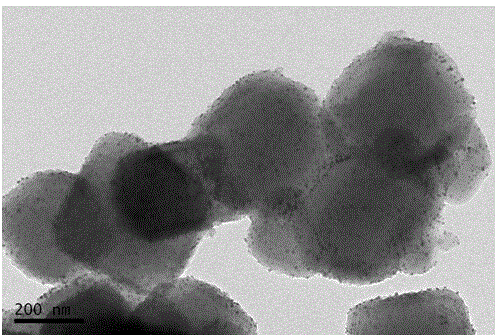

Image

Examples

Embodiment 1

[0036] 12g of acrylonitrile, 1.2g of divinylbenzene, 0.8g of hexadecane, 2.4g of isooctane, 10g of ethyl orthosilicate, 1.0g of γ-(methacryloyloxy)propyltrimethoxysilane and 0.2 g azobisisoheptanonitrile was magnetically stirred for 30 minutes to fully dissolve it as an oil phase;

[0037]Weigh 0.02g of sodium nitrite and dissolve it in deionized water with magnetic stirring for 10min to fully dissolve it as the water phase; slowly add the oil phase into the water phase, then add 1g of triethylamine, stir magnetically at room temperature for 30min to form a mixed solution; Then use a high-speed shearing device to homogeneously emulsify for 5 minutes at a shear rate of 16000 rpm under an ice-water bath to form a fine emulsion;

[0038] Transfer the fine emulsion to a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, pass nitrogen gas for 30 minutes under stirring to remove the air in the system, and react at a constant temperature in a water bath...

Embodiment 2

[0040] 12g of acrylonitrile, 1.2g of divinylbenzene, 0.8g of hexadecane, 1.2g of isooctane, 10g of ethyl orthosilicate, 1.0g of γ-(methacryloyloxy)propyltrimethoxysilane and 0.2 g azobisisoheptanonitrile was magnetically stirred for 30 minutes to fully dissolve it as an oil phase;

[0041] Weigh 0.02g of sodium nitrite and dissolve it in deionized water and stir it magnetically for 10 minutes to make it fully dissolved as the water phase;

[0042] Slowly add the oil phase to the water phase, then add 1g of triethylamine, stir magnetically at room temperature for 30 minutes to form a mixed solution; then use a high-speed shearing device in an ice-water bath to homogeneously emulsify at a shear rate of 16000rpm for 5 minutes to form a fine emulsion ;

[0043] Transfer the fine emulsion to a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, pass nitrogen gas for 30 minutes under stirring to remove the air in the system, and react at a constant tem...

Embodiment 3

[0045] 12g of acrylonitrile, 1.2g of divinylbenzene, 0.8g of hexadecane, 2.4g of isooctane, 10g of ethyl orthosilicate, 2.0g of γ-(2,3-epoxypropoxy)propyltrimethoxy Silane and 0.2 g of azobisisoheptanonitrile were magnetically stirred for 30 minutes to fully dissolve it as an oil phase;

[0046] Weigh 0.02g of sodium nitrite and dissolve it in deionized water with magnetic stirring for 10min to fully dissolve it as the water phase; slowly add the oil phase into the water phase, then add 1g of triethylamine, stir magnetically at room temperature for 30min to form a mixed solution; Then use a high-speed shearing device to homogeneously emulsify for 5 minutes at a shear rate of 16000 rpm under an ice-water bath to form a fine emulsion;

[0047] Transfer the fine emulsion to a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, pass nitrogen gas for 30 minutes under stirring to remove the air in the system, and react at a constant temperature in a wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com