Preparation of keratin-sodium alginate composite microporous gel and application of gel as drug carrier

A technology of sodium alginate and keratin, which is applied in the direction of drug combinations, medical preparations of non-active ingredients, non-active ingredients of polymer compounds, etc., to achieve good swelling and deswelling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

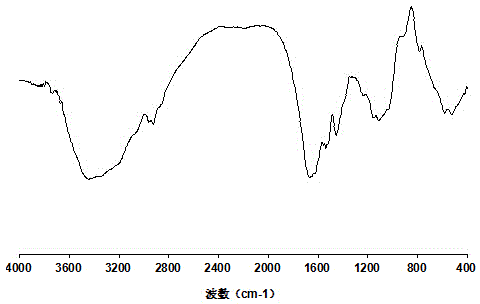

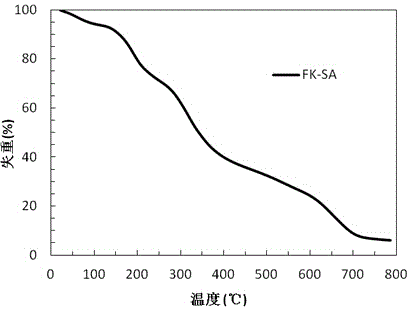

Image

Examples

Embodiment 1

[0044] Dissolve 0.1 g of feather keratin in 2 mL of 0.8 mol / L urea solution, under the protection of inert gas, add 2 mg of dithiothreitol, stir at 30 ° C for 80 min for reduction reaction; add 0.1 g of sodium alginate After stirring for 10 minutes, add 25 mg of organic cross-linking agent N, N-methylenebisacrylamide and mix well, add 1.5 mg of initiator ammonium persulfate and stir for 0.5-3 hours, then add 0.08 g of inorganic cross-linking agent calcium chloride, and continue stirring React for 0.1 h; then let the reaction solution stand at 60°C for 6 h; soak in ethanol and water, wash and freeze-dry to obtain keratin-sodium alginate composite microporous gel. The composite microporous gel has a cumulative release rate of 82% for doxorubicin hydrochloride at body temperature (37°C).

Embodiment 2

[0046] Dissolve 1.0 g of feather keratin in 5 mL of sodium hydroxide solution with a concentration of 1.0 mol / L, under the protection of inert gas, add 10 mg of dithiothreitol, stir at 45°C for 60 min; add 0.5 mg of sodium alginate , after stirring for 15 min, add 50 mg of organic cross-linking agent N,N-methylenebisacrylamide and mix well, add 15 mg of initiator ammonium persulfate and stir for 1 h, then add 0.1 g of inorganic cross-linking agent calcium chloride, continue The reaction was stirred for 0.5 h; then the reaction solution was left standing at 85°C for 3 h; soaked in ethanol and water, washed and freeze-dried to obtain a keratin-sodium alginate composite microporous gel. The composite microporous gel has a cumulative release rate of 76% for doxorubicin hydrochloride at body temperature (37°C).

Embodiment 3

[0048] Dissolve 2.0 g of feather keratin in 10 mL of urea solution with a concentration of 2.0 mol / L, add 100 mg of mercaptoethanol under the protection of inert gas, and stir at 65°C for 40 min for reduction reaction; add 1.0 g of sodium alginate and stir for 30 min After 1 min, add 100 mg of organic cross-linking agent N,N-methylenebisacrylamide and mix well, add 50 mg of initiator ammonium persulfate and stir for 3 h, then add 0.5 g of inorganic cross-linking agent magnesium chloride, and continue stirring for 1 h; Then the reaction solution was left to stand at 70°C for 4 h; soaked in ethanol and water, washed and freeze-dried to obtain a keratin-sodium alginate composite microporous gel. The composite microporous gel has a cumulative release rate of 81% for doxorubicin hydrochloride at body temperature (37°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| cumulative release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com