Modified aqueous alkyd resin coating

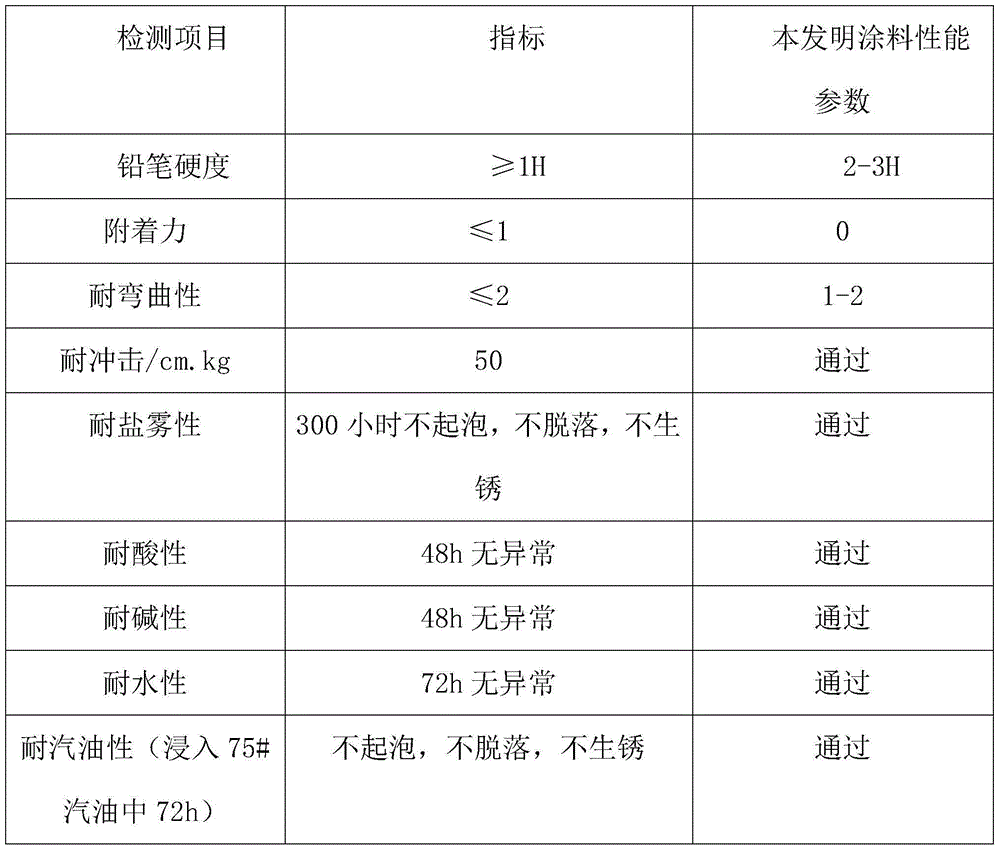

A technology of water-based alkyd resin and water-based epoxy resin, applied in the field of coatings, can solve the problems of alkyd resin coating hardness, poor water resistance and corrosion resistance, impact on human body and ecological environment, etc., and achieve good self-drying, Effect of shortening drying time and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023]A kind of modified water-based alkyd resin coating that the present invention proposes, its raw material comprises the following components by weight: 70 parts of acrylic modified water-based alkyd resins, 25 parts of water-based epoxy resins, 10 parts of nano-silica sols, 5 parts of amino resins 2 parts, 2 parts of rutile titanium dioxide, 6 parts of nano-calcium carbonate, 1 part of nano-titanium dioxide, 5 parts of aluminum oxide, 2 parts of nano-iron oxide, 0.5 parts of nano-silver, 0.3 parts of polyethylene glycol, 0.5 parts of propylene glycol methyl ether, and 0.2 parts of butyl glycol ether, 1.5 parts of triethanolamine, 0.1 part of benzotriazole, 0.5 parts of dispersant, 0.1 part of defoamer, 4 parts of lanthanum stearate, 1 part of silane coupling agent, and 50 parts of water.

Embodiment 2

[0025] A kind of modified water-based alkyd resin coating that the present invention proposes, its raw material comprises the following components by weight: 85 parts of acrylic acid modified water-based alkyd resins, 10 parts of water-based epoxy resins, 25 parts of nano-silica sols, 2 parts of amino resins 5 parts of rutile titanium dioxide, 2 parts of nano-calcium carbonate, 4 parts of nano-titanium dioxide, 2 parts of aluminum oxide, 6 parts of nano-iron oxide, 0.1 part of nano-silver, 1 part of polyethylene glycol, 0.1 part of propylene glycol methyl ether, and 1 part of butyl glycol ether, 0.5 part of triethanolamine, 0.5 part of benzotriazole, 0.05 part of dispersant, 0.8 part of defoamer, 0.3 part of zirconium isooctanoate, 0.7 part of cerium stearate, 3 parts of silane coupling agent , 20 parts of water;

[0026] Wherein, the average particle diameter of the nano-silica sol is 20nm; the average particle diameter of the nano-calcium carbonate is 35nm; the average parti...

Embodiment 3

[0028] A kind of modified water-based alkyd resin coating that the present invention proposes, its raw material comprises the following components by weight: 79 parts of acrylic modified water-based alkyd resins, 19 parts of water-based epoxy resins, 20 parts of nano-silica sols, 4 parts of amino resins 3.6 parts, 3.6 parts of rutile titanium dioxide, 4.2 parts of nano-calcium carbonate, 3.1 parts of nano-titanium dioxide, 3.7 parts of alumina, 4.6 parts of nano-iron oxide, 0.32 parts of nano-silver, 0.65 parts of polyethylene glycol, 0.4 parts of propylene glycol methyl ether, ethyl 0.55 parts of glycol butyl ether, 1 part of triethanolamine, 0.4 parts of benzotriazole, 0.4 parts of dispersant, 0.68 parts of defoamer, 3.4 parts of drier, 2.5 parts of silane coupling agent, 40 parts of water;

[0029] Wherein, the average particle diameter of the nano-silica sol is 35nm; the average particle diameter of the nano-calcium carbonate is 10nm; the average particle diameter of the na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com