A method for large-scale production of polyester staple fiber using PET bottle flakes

A technology of polyester staple fiber and bottle flakes, applied in the field of polyester staple fiber production, can solve problems such as unfavorable spinning, high melt viscosity, high stability requirements, unstable production, etc., to solve inconsistent drying quality and meet various varieties The effect of softening and shortening the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for large-scale production of polyester staple fibers utilizing PET bottle flakes is characterized in that it specifically comprises the steps:

[0033] (1) Raw material pretreatment: Clean and remove the recycled PET bottles, crush them into flakes and dry them with a pulverizer, control the pressure of the cyclone separator to 1100-1250Pa, and the gas volume to 3800-4100m 3 / h, separate the dust in the bottle flake material from the fine bottle flake powder, and dry it in a vacuum drying drum. The drying time is 8-10 hours, and the moisture content after drying is ≤0.015%;

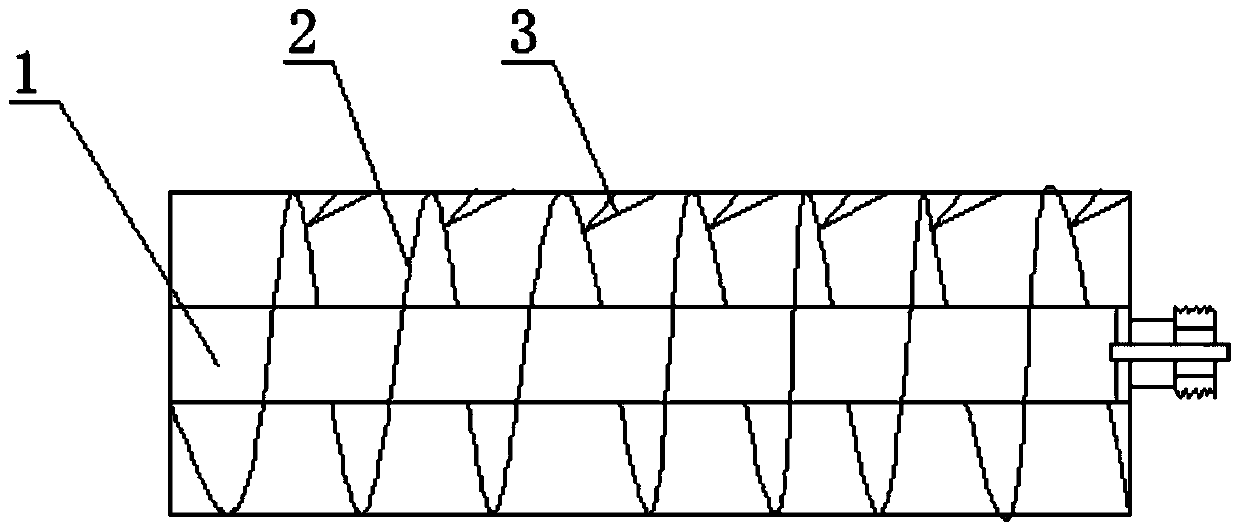

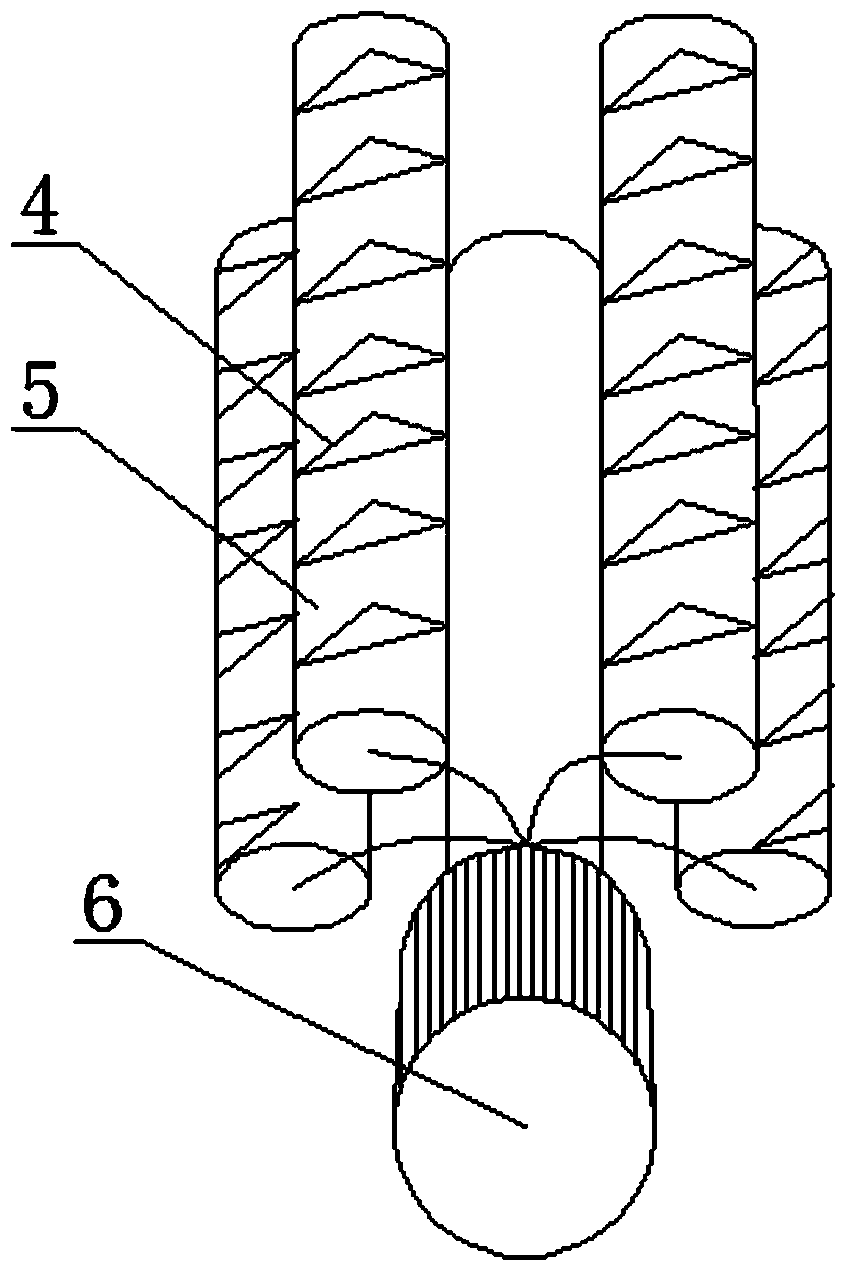

[0034](2) Melt filtration: The dried bottle flakes enter the screw extruder for extrusion and melting. The temperature in the cooling zone of the screw extruder is ≤100°C, and the temperature in the first to sixth areas is 282-310°C. The viscosity is 0.560±0.001dl / g~0.715±0.001dl / g, the screw outlet pressure is 7.5±0.1MP, and the obtained melt is sent to a two-stage filter device for fil...

Embodiment 2

[0048] When producing 1.67dtex dyeable, cotton-type polyester staple fiber, the production process is as follows:

[0049] A method for large-scale production of polyester staple fibers utilizing PET bottle flakes is characterized in that it specifically comprises the steps:

[0050] (1) Raw material pretreatment: recycle PET bottles with intrinsic viscosity IV=0.740dl / g bottle flakes, wash and remove impurities from the recovered PET bottles, then crush them into flakes and dry them, and use the hot cyclone separation method of cyclone separator Separate the dust and fine bottle flake powder in the bottle flakes, and dry them in a vacuum drying drum equipped with a built-in agitator. The drying temperature of the drum is controlled at 135-145 °C, and the drum speed is 4- 6r / min, the drying time is 8-10 hours, the moisture content of incoming raw materials is ≤5.0-6.0%; the moisture content after drying is ≤0.015%;

[0051] (2) Melt filtration: the dried bottle flakes enter t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com