Method for measuring contents of potassium, sodium, lead, zinc, arsenic and copper in ferrous metallurgy materials

A determination method and technology of iron and steel metallurgy, applied in the field of determination of arsenic, sodium, potassium, zinc, lead and copper content in iron and steel metallurgical materials, can solve the problem of difficult to meet the requirements of multi-element analysis, complicated photometric steps, and large reagent consumption and other issues, to achieve significant economic and social benefits, expand coverage, and be easy to master.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Get 0.1g of iron ore that does not contain potassium, sodium, lead, zinc, arsenic and copper as a matrix sample, then utilize the mixed acid dissolution of hydrochloric acid, hydrofluoric acid and perchloric acid, the addition of the hydrochloric acid Amount is 55ml / g sample; The addition amount of described hydrofluoric acid is 15ml / g sample; The addition amount of described perchloric acid is 25ml / g sample, obtains the first sample solution, then the second The first sample solution was evaporated to dryness, then added twice distilled water and evaporated to dryness three times, and then dissolved with hydrochloric acid, the amount of hydrochloric acid added was 55ml / g sample, and the acidity was adjusted at the same time to obtain the second sample solution, and the second solution was divided into 6 equal parts.

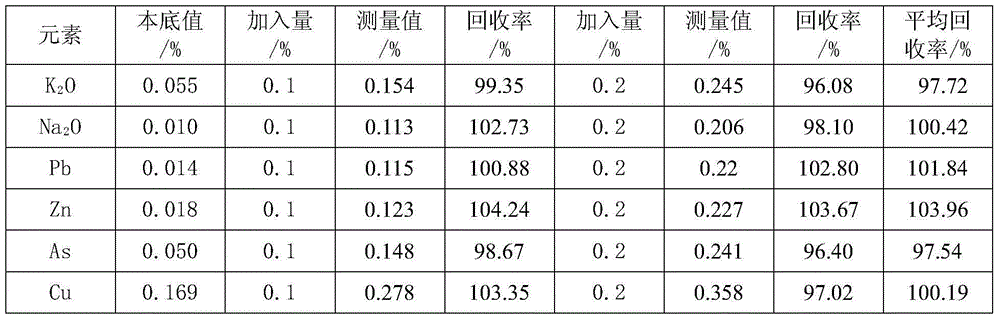

[0047] Then, 6 mixed solutions were prepared, the mixed solutions contained potassium, sodium, lead, zinc, arsenic and copper elements with known conc...

Embodiment 2

[0050] 1) Get 0.1g of iron ore that does not contain potassium, sodium, lead, zinc, arsenic and copper as a matrix sample, then utilize the mixed acid dissolution of hydrochloric acid, hydrofluoric acid and perchloric acid, the addition of the hydrochloric acid Amount is 45ml / g sample; The addition amount of described hydrofluoric acid is 25ml / g sample; The addition amount of described perchloric acid is 35ml / g sample, obtains the first sample solution, then the second The first dissolved sample solution was evaporated to dryness, then added twice-distilled water and evaporated to dryness three times, and then dissolved with hydrochloric acid. The amount of hydrochloric acid added was 45ml / g sample, and the acidity was adjusted simultaneously to obtain the second dissolved sample solution. 6 equal parts.

[0051]Then, 6 mixed solutions were prepared, the mixed solutions contained potassium, sodium, lead, zinc, arsenic and copper elements with known concentrations, and the conc...

Embodiment 3

[0054] 1) Get 0.1g of iron ore that does not contain potassium, sodium, lead, zinc, arsenic and copper as a matrix sample, then utilize the mixed acid dissolution of hydrochloric acid, hydrofluoric acid and perchloric acid, the addition of the hydrochloric acid Amount is 50ml / g sample; The addition amount of described hydrofluoric acid is 20ml / g sample; The addition amount of described perchloric acid is 30ml / g sample, obtains the first sample solution, then the second The first sample solution was evaporated to dryness, then added twice distilled water and evaporated to dryness three times, and then dissolved with hydrochloric acid. The amount of hydrochloric acid added was 50ml / g sample, and the acidity was adjusted at the same time to obtain the second sample solution. The second solution was divided into 6 equal parts.

[0055] Then, 6 mixed solutions were prepared, the mixed solutions contained potassium, sodium, lead, zinc, arsenic and copper elements with known concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com