Drain current-improved thin film transistor

A thin-film transistor and drain current technology, which is applied in the direction of transistors, circuits, electrical components, etc., can solve the problems of carrier mobility decline, carrier occupation energy state density, jumping difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

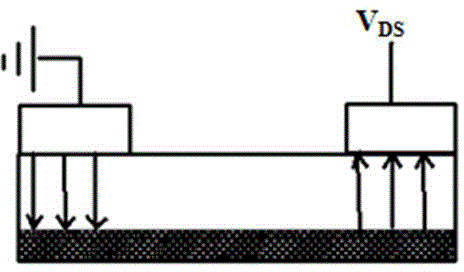

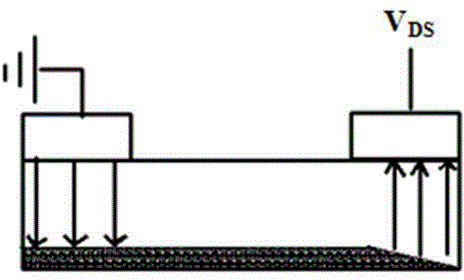

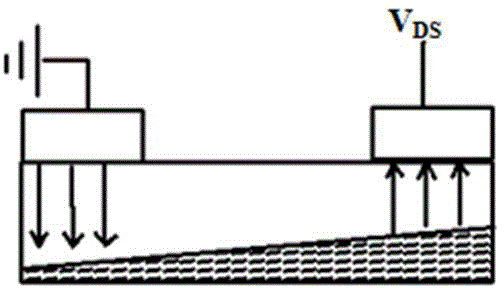

Image

Examples

Embodiment 1

[0040] N-type doping is carried out on the semiconductor layer, and the preparation scheme of each structural layer is as follows:

[0041] (1) A layer of 104 zinc oxide (ZnO) is sputtered on the 102 insulating layer film by sputtering process, and the thickness is controlled at 50-300nm;

[0042] (2) Indium is implanted into the active layer 104 by means of ion implantation. By controlling the energy and dose, the doped layer 103 presents a gradient shape. The implanted energy is set at 50-100kV, and the indium is doped according to the energy In a gradient shape, the dose is controlled at 1×10 16 / cm 2 ;

[0043] (3) The doped device is annealed in air, and the annealing temperature is 980°C;

[0044] (4) Depositing an aluminum film on the active layer 104 by vacuum evaporation technology;

[0045] (5) Use a spin coater to spin coat a layer of photoresist on the aluminum film, and then bake and cure;

[0046] (6) Use a specific mask to expose it to ultraviolet rays;

...

Embodiment 2

[0052] P-type doping is performed on the semiconductor layer, the substrate is Si, and the insulating layer is SiO 2 , the source and drain electrodes are Al, the preparation scheme of each structure is similar to that of Example 1, and the doping material is replaced by P 2 o 5 , ionized with an ion implanter and then doped with phosphorus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com