A three-primary-color photodetection method based on radial junction stack structure

A photoelectric detection and layer structure technology, applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of cumbersome junction area production, complex material preparation, and reduced detection performance, and achieve low cost, good sensitivity, and work. The effect of low voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

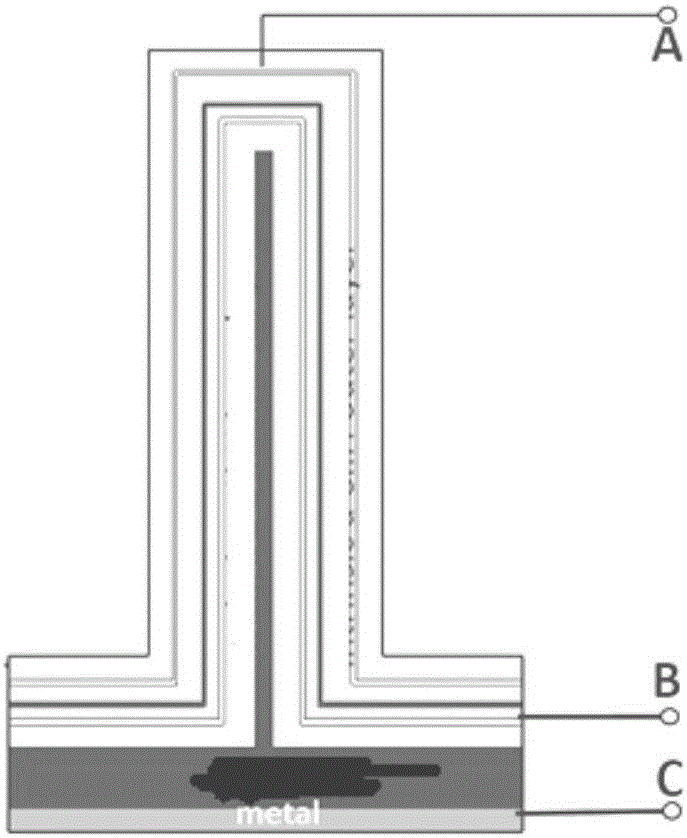

[0032] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following in conjunction with specific examples, and with reference to the appended figure 1 , to further describe the present invention in detail. A, B, and C in the figure are electrodes with a stacked PIN structure.

[0033] 1) A common glass sheet with a thickness of about 1mm is used as the substrate;

[0034] 2) Use the conventional cleaning method on the surface of the substrate, and after cleaning, sputter a layer of about 1 layer of aluminum-doped zinc oxide (AZO) film as the bottom electrode;

[0035] 3) Evaporating a 1-2nm Sn film on the surface of the substrate as a catalyst;

[0036] 4) In PECVD, treat with hydrogen at 320, power 10W, and 30Pa for 5 minutes to form Sn particles with a diameter of about 20-40nm; heat up to 520 and feed silane and borane, and grow at a power of 20W with a diameter of about 40nm and a length of About 1 p-type silicon nanow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com