Landfill leachate anaerobic biogas purification method

A technology of landfill leachate and purification method, which is applied to the field of purification and purification of biogas produced by anaerobic fermentation of urban domestic landfill leachate, can solve the problems of complex biogas composition and inability to realize anaerobic biogas purification and purification of landfill leachate, and achieve purification High efficiency and the effect of reducing the content of water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

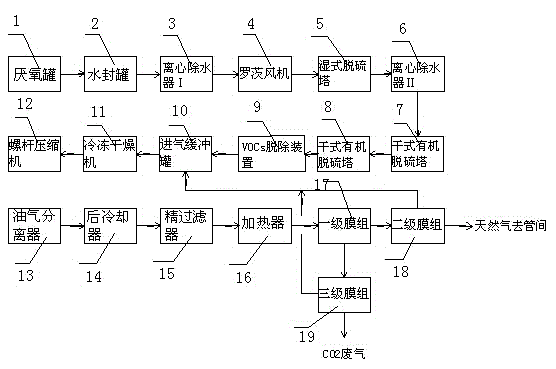

[0043] Below in conjunction with accompanying drawing, content of the present invention is described further:

[0044] As shown in the figure is the flow chart of the anaerobic biogas purification and purification method for landfill leachate, including an anaerobic tank 1, a water-sealed tank 2 connected to the anaerobic tank 1, and a centrifugal water eliminator I3 connected to the water-sealed tank 2, Roots blower 4 is connected to water eliminator Ⅰ3, wet desulfurization tower 5 is connected to roots blower 4, centrifugal dehydrator Ⅱ6 is connected to wet desulfurization tower 5, and dry desulfurization tower Ⅱ6 is connected to centrifugal dehydrator Ⅱ6. Hydrogen sulfide desulfurization tower 7, dry type hydrogen sulfide desulfurization tower 7 is connected with dry type organic sulfur desulfurization tower 8, is connected with VOCs removal device 9 on dry type organic sulfur desulfurization tower 8, is connected with VOCs removal device 9 The intake buffer tank 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com