Preparation method of magnetic biological microcapsule for processing organic matters and ammonia nitrogen in water

A technology for organic matter and water treatment, applied in the direction of fixing on/in organic carriers, fixing on or in inorganic carriers, etc., can solve the problems of microbial instability and large environmental impact, and achieve good biocompatibility , uniform particle size, good adsorption and permeability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

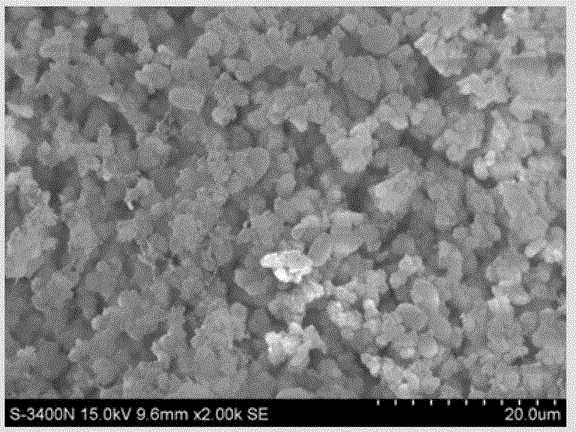

Image

Examples

Embodiment 1

[0018] Embodiment 1: the preparation method of a kind of magnetic biological microcapsule of the present invention is as follows:

[0019] 2% calcium chloride solution and 7.0% normal saline were prepared in advance, both in mass concentration.

[0020] (1) Add 1ml of Candida seed solution into 150ml of YPD medium, inoculate the concentration of Candida seed solution, preferably above 1.5 in terms of OD value, and place it in a constant temperature air bath incubator for cultivation. 180rpm, 26°C, after 5.5h, take 20ml of the strain solution in the logarithmic phase, the OD value is 1.3, dry and freeze at low temperature, 3500rpm, 5.5min. Pour off the supernatant and wash 3 times with 7% saline. Suspend the extracted strains with 10ml of normal saline, and oscillate on a vortex shaker to mix evenly to make a suspension of yeast strains, with an OD value of about 1.6.

[0021] (2) Weigh 0.2g sodium alginate and 0.02g Fe 3 o 4 After mixing the powder, add about 9ml of deioni...

Embodiment 2

[0024] Embodiment 2: the preparation method of a kind of magnetic biological microcapsule of the present invention:

[0025] Pre-prepared 2.1% calcium chloride solution, 6% saline, both in mass concentration.

[0026] (1) Add 1ml of Candida seed solution into 140ml of YPD medium, inoculate the concentration of Candida seed solution, preferably above 1.5 in terms of OD value, and place it in a constant temperature air bath incubator for cultivation. 200rpm, 25°C, after 5h, take 20ml of the strain solution in the logarithmic phase, the OD value is 1.2, dry and freeze at low temperature, 4000rpm, 5min. Pour off the supernatant and wash 3.5 times with 6% saline. Suspend the extracted strains with 10ml of normal saline, and oscillate on a vortex shaker to mix evenly to make a suspension of yeast strains with an OD value of about 1.5.

[0027] (2) Weigh 0.19g sodium alginate and 0.018g Fe 3 o 4 After mixing the powder, add about 9ml of deionized water, heat until the sodium algi...

Embodiment 3

[0029] Embodiment 3: the preparation method of a kind of magnetic biological microcapsule of the present invention:

[0030] Pre-prepared 1.9% calcium chloride solution, 8% saline, both in mass concentration.

[0031] (1) Add 1ml of Candida seed solution into 160ml of YPD medium, inoculate the concentration of Candida seed solution, preferably above 1.5 in terms of OD value, and place it in a constant temperature air bath incubator for cultivation. 150rpm, 28°C, after 6h, take 20ml of the strain solution in the logarithmic phase, the OD value is 1.4, dry and freeze at low temperature, 3000rpm, 6min. Pour off the supernatant and wash 4 times with 8% saline. Suspend the extracted strains with 10ml of normal saline, and oscillate on a vortex shaker to mix evenly to make a suspension of yeast strains, with an OD value of about 1.8.

[0032] (2) Weigh 0.21g sodium alginate and 0.022g Fe 3 o 4 After mixing the powder, add about 9ml of deionized water, heat until the sodium algin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com