Heavy denier polyester industrial yarn and processing apparatus thereof

A technology of polyester industrial yarn and processing device, which is applied in the field of polyester processing, can solve the problems of polyester industrial yarn production, unstable quality indicators, inability to process heavy denier, etc., and achieves stable quality, good product quality stability, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

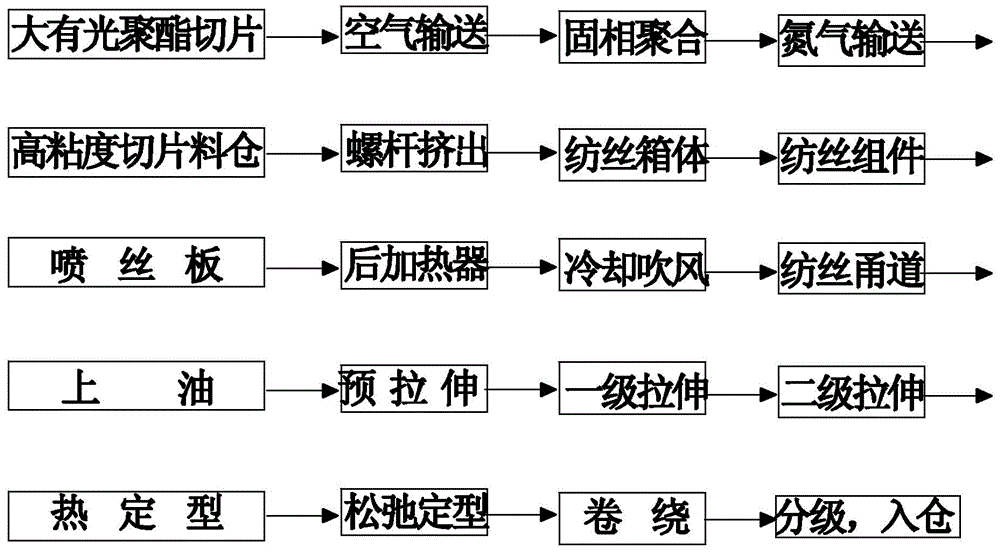

[0037] Example 1: 12 heads spinning 5000D high-strength polyester industrial yarn

[0038] (1) Solid phase viscosity increase:

[0039] Bright polyester chips with an intrinsic viscosity of 0.64-0.69dl / g are used, transported to the crystallizer, and after being crystallized by hot air at 180°C, the chips are introduced into the solid-phase polymerization tower through a rotary valve, and passed through a temperature of 200-220°C And after 30-38 hours, a high-viscosity polyester chip with an intrinsic viscosity of 0.95-1.05 dl / g was obtained.

[0040] (2) Multi-head spinning:

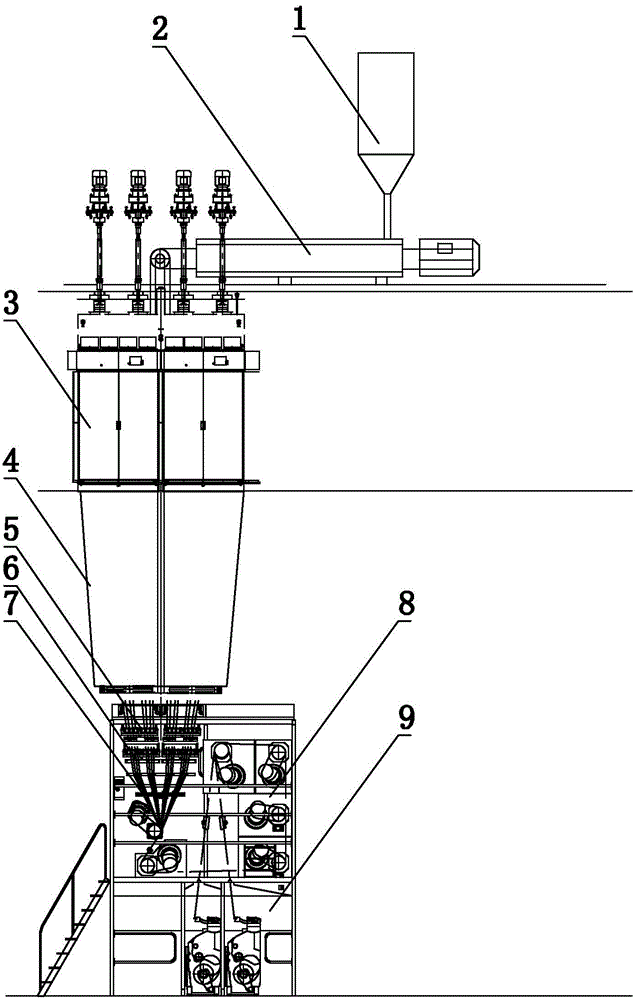

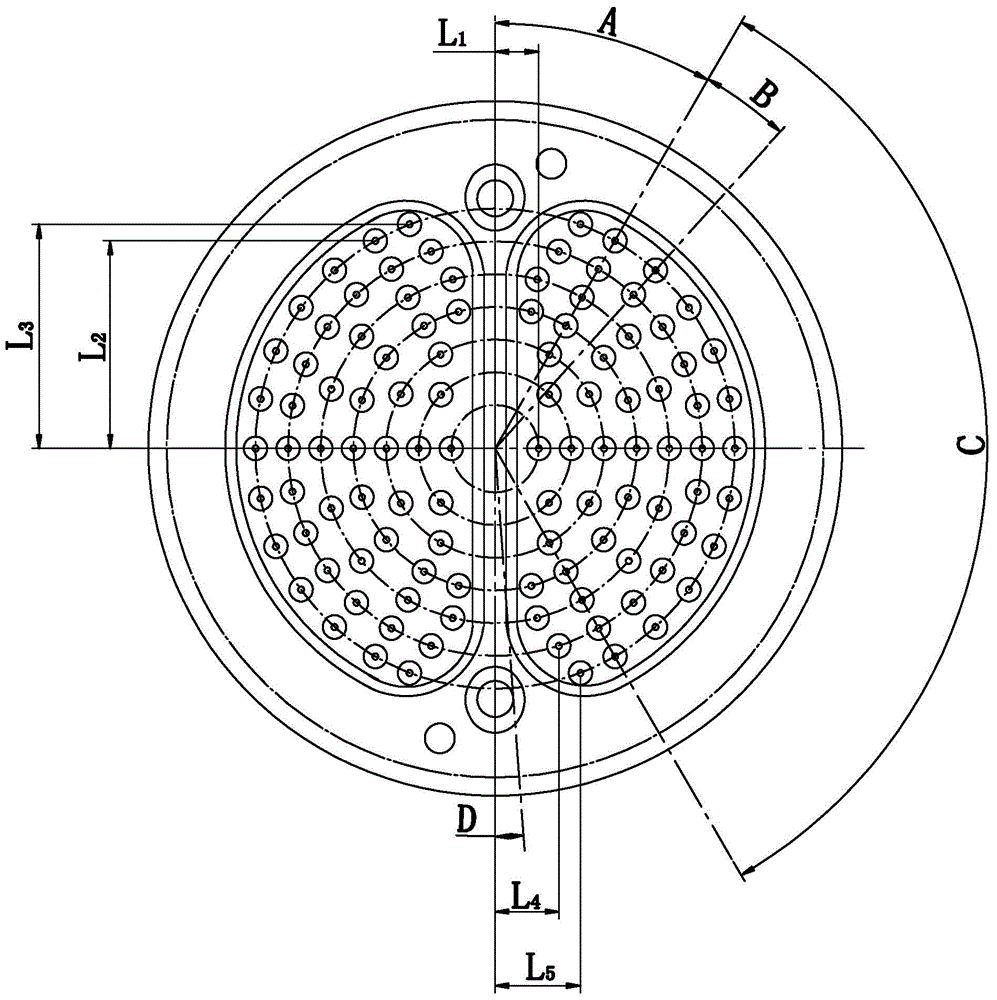

[0041] combine figure 1 and figure 2, the high-viscosity polyester chips after viscosification are transported to the pre-spinning silo 1, melted by the spinning screw of the screw extruder 2, each spinning position uses 12 spinning heads, and the temperature of the spinning box 3 290~300℃, the melt is metered and filtered by the metering pump, and then sprayed out from the spinneret. After passing...

Embodiment 2

[0050] Example 2: 12 heads spinning 6000D heavy denier polyester industrial yarn

[0051] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that:

[0052] (1) Solid phase viscosity increase:

[0053] Bright polyester chips with an intrinsic viscosity of 0.64-0.69dl / g are used, transported to the crystallizer, and after being crystallized by hot air at 180°C, the chips are introduced into the solid-phase polymerization tower through a rotary valve, and passed through a temperature of 200-220°C And after 30-38 hours, a high-viscosity polyester chip with an intrinsic viscosity of 0.90-1.10 dl / g was obtained.

[0054] (2) Multi-head spinning:

[0055] The melt after solid-phase viscosity increase is transported to each spinning screw, the heating temperature is 285-298°C, the temperature of the spinning box is 290-300°C, each spinning position contains a parallel spinning box, each box The body is equipped with 4 planet...

Embodiment 3

[0060] Example 3: 12 heads spinning 4500D heavy denier polyester industrial yarn

[0061] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that:

[0062] (1) Solid phase viscosity increase:

[0063] Bright polyester chips with an intrinsic viscosity of 0.64-0.69dl / g are used, transported to the crystallizer, and after being crystallized by hot air at 180°C, the chips are introduced into the solid-phase polymerization tower through a rotary valve, and passed through a temperature of 200-220°C And after 30-38 hours, a high-viscosity polyester chip with an intrinsic viscosity of 0.90-1.10 dl / g was obtained.

[0064] (2) Multi-head spinning:

[0065] The melt after solid-phase viscosity increase is transported to each spinning screw, the heating temperature is 285-298°C, the temperature of the spinning box is 290-300°C, each spinning position contains a parallel spinning box, each box The body is equipped with 4 planet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Denier | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com