Preparation method for detachable esophageal stent

A technology of esophagus and braided sheet, which is applied in the field of preparation of decomposable esophageal stents, which can solve the problems of unguaranteed treatment effect and short maintenance time, and achieve the effect of good radial support force and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also includes a method for preparing a decomposable esophageal stent, comprising the following steps:

[0025] ① Use lactide and glycolide as raw materials to synthesize poly(lactic acid-glycolic acid) copolymer;

[0026] ② extruding and stretching the poly(lactic acid-glycolic acid) copolymer obtained in step ① to obtain stretched filaments;

[0027] ③ Making the stent alloy wire braided sheet, heat-treating it, and then coating it to obtain the film-coated woven sheet; the stent alloy wire braided sheet uses a rhombus weaving method; the temperature of the heat treatment is 510-600°C, and the time is 20 ~30 minutes; the specific step of the coating film treatment is to soak the heat-treated stent alloy wire braided sheet with absolute alcohol for 1 to 2 minutes, then dry it, immerse it in a silicone rubber solution with a mass fraction of 5~10%, and coat Cover evenly, take it out and dry it in a drying oven, put it in an oven and dry it at 120°C...

Embodiment 1

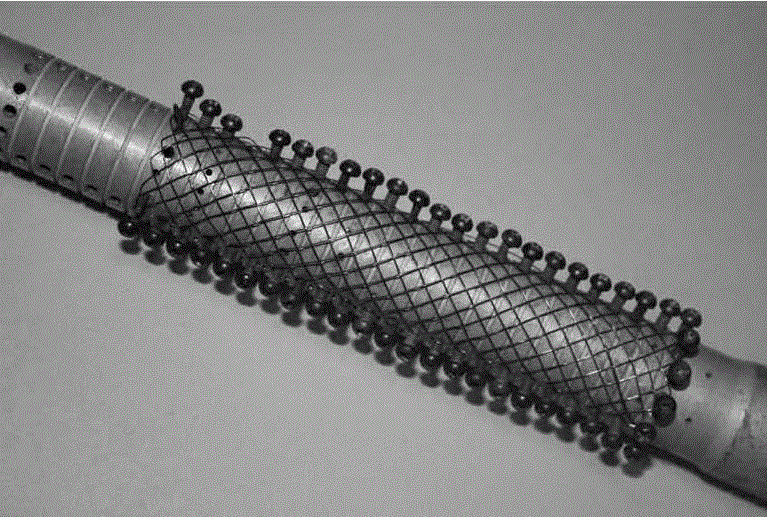

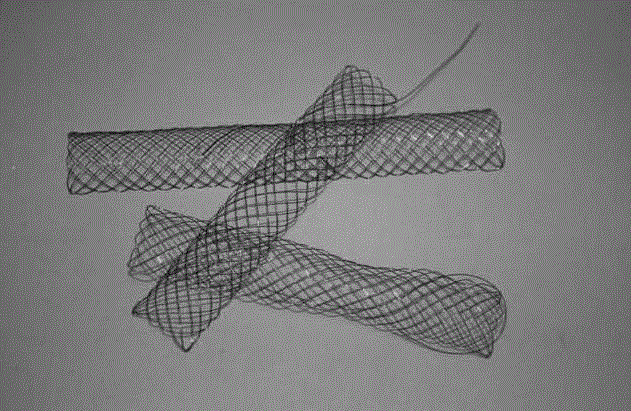

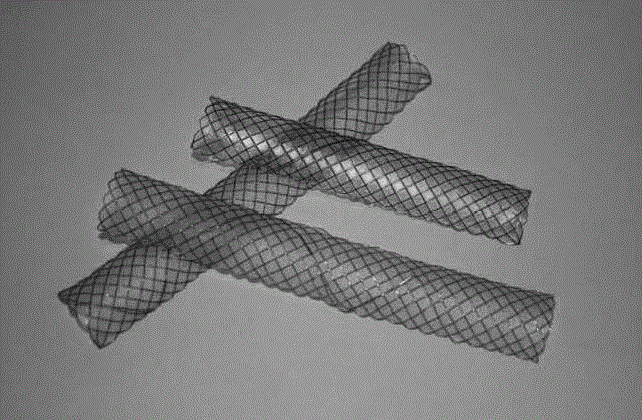

[0033] A decomposable esophageal stent, consisting of three stent alloy wire braided sheets, the surface of the stent alloy wire braided sheet is coated with a layer of silicone rubber, and the stent alloy wire braided sheet is made of poly(lactic acid-glycolic acid) copolymerized The objects are connected by suture, and the composition material of the stent alloy wire braid is nickel-titanium memory alloy.

[0034] ① Use lactide and glycolide as raw materials to synthesize poly(lactic acid-glycolic acid) copolymer;

[0035] ② extruding and stretching the poly(lactic acid-glycolic acid) obtained in step ① to obtain stretched silk;

[0036] ③ Making the stent alloy wire braided sheet, heat-treating it, and then coating it to obtain the coated woven sheet; the stent alloy wire braided sheet uses a rhombus weaving method; the temperature of the heat treatment is 510° C., and the time is 20 minutes; The specific steps of the coating film treatment are soaking the heat-treated ste...

Embodiment 2

[0039] A decomposable esophageal stent, consisting of three stent alloy wire braided sheets, the surface of the stent alloy wire braided sheet is coated with a layer of silicone rubber, and the stent alloy wire braided sheet is made of poly(lactic acid-glycolic acid) copolymerized The objects are connected by suture, and the composition material of the stent alloy wire braid is nickel-titanium memory alloy.

[0040] ① Use lactide and glycolide as raw materials to synthesize poly(lactic acid-glycolic acid) copolymer;

[0041] ② extruding and stretching the poly(lactic acid-glycolic acid) obtained in step ① to obtain stretched silk;

[0042] ③ Making the stent alloy wire braided sheet, heat-treating it, and then coating it to obtain the film-coated woven sheet; the stent alloy wire braided sheet uses a rhombus weaving method; the temperature of the heat treatment is 600° C., and the time is 30 minutes; The specific steps of the coating film treatment are soaking the heat-tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com