A kind of triphenyl waste gas adsorption liquid and its application

A technology for adsorbing liquid and waste gas, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as immature processes, and achieve the effects of improving the surrounding environment, increasing the absorption rate, and reducing relative volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The freon recovery solution in this embodiment adopts freon R22, freon R12, etc., which are commonly used in air conditioners and refrigerator refrigeration. Freon recovery solutions with different concentrations have different absorption effects on waste gas. The triphenyl waste gas adsorption liquid in this embodiment is Made as follows:

[0024] 1. The components and proportioning are: 18 parts by weight of emulsion, 1 part by weight of surfactant, 1 part by weight of sodium carboxymethylcellulose and 8000 parts by weight of water. The surfactant used in this embodiment is fatty acid glyceride;

[0025] 2. The production method is:

[0026] Step 1: Production of the emulsion: add Freon recovery solution and N-formylmorpholine in sequence in the reaction kettle according to the proportion, turn on the reaction kettle and stir, stir for 3 hours until completely dissolved, and form the FN-1 emulsion;

[0027] Step 2: Preparation of triphenyl waste gas adsorption liquid...

Embodiment 2

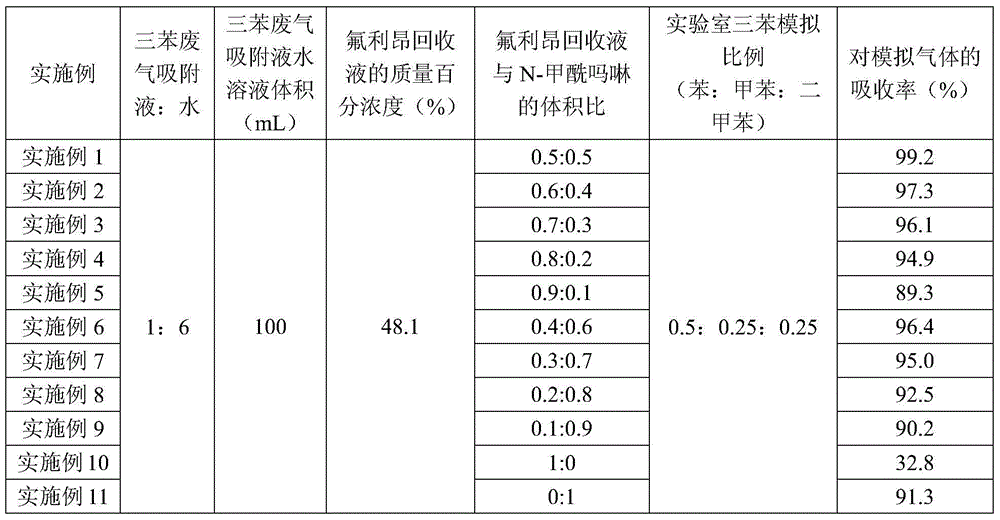

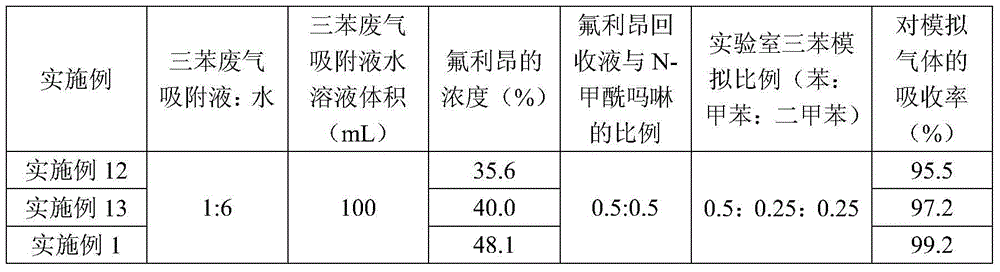

[0031] The difference between the triphenyl exhaust gas adsorption solution described in this implementation and Example 1 is that the Freon recovery solution in the emulsion: N-formylmorpholine=0.6:0.4, and the surfactant used is sucrose fatty acid ester. It is simulated in the laboratory, and its absorption effect is shown in Table 1.

Embodiment 3

[0033] The difference between the triphenyl waste gas adsorption liquid described in this implementation and Example 1 is that the Freon recovery liquid in the emulsion: N-formylmorpholine=0.7:0.3, the mixture of the surfactant fatty acid glyceride and sucrose fatty acid lipid used , the mass ratio of fatty acid glyceride to sucrose fatty acid lipid is 1:1. It is simulated in the laboratory, and its absorption effect is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com