A method of porous carbon supporting metal carbides

A carbide and porous carbon technology, applied in chemical instruments and methods, chemical/physical processes, catalyst carriers, etc., can solve the problems of serious pollution, long synthesis routes, and high cost of template agents, and achieve great application prospects and synthesis routes. Simple, avoid complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Mo supported on porous carbon 2 C

[0026] Synthetic raw materials: glucose, urea, ammonium molybdate

[0027] (1) Weigh 1 g glucose, 0.01 g urea and 0.1 g H 24 Mo 7 N 6 o 24 4H 2 O in a 100 mL beaker, then grind the medicine in the beaker with a mortar for 20 minutes to make it even, and form a molten state at a certain temperature;

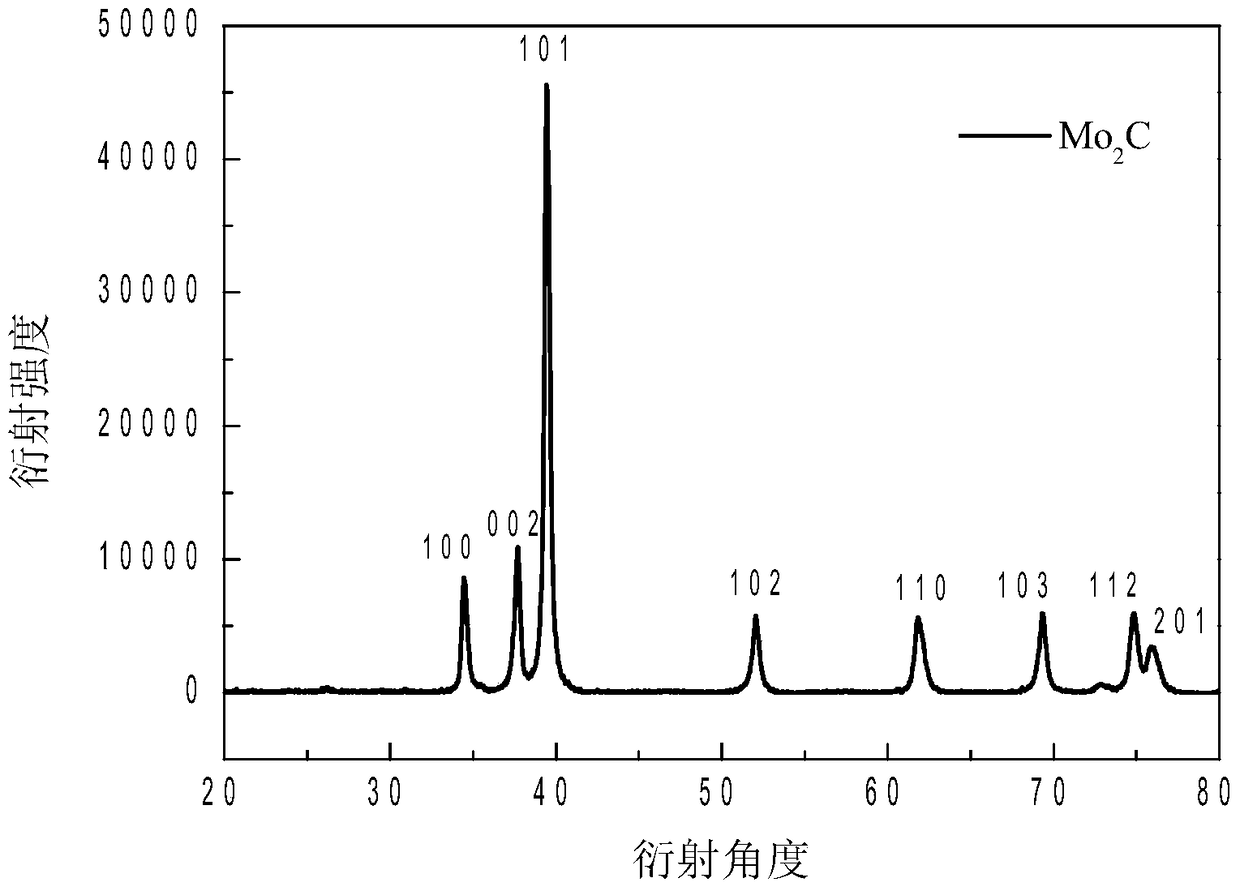

[0028] (2) Put the mixture described in (1) in the crucible and place it in a tube furnace, and put the sample at 800°C, N 2 Calcined for 5 hours under the same conditions to obtain a dark brown bulky solid, which was measured by XRD as porous carbon supported molybdenum carbide (Mo 2 C).

Embodiment 2

[0029] Example 2: Mo supported on porous carbon 2 C

[0030] Synthetic raw materials: glucose, urea, ammonium molybdate

[0031] (1) Weigh 0.02 g glucose, 2 g urea and 0.2 g H 24 Mo 7 N 6 o 24 4H 2 O in a 100 mL beaker, then grind the medicine in the beaker with a mortar for 30 minutes, and then heat it to form a molten state;

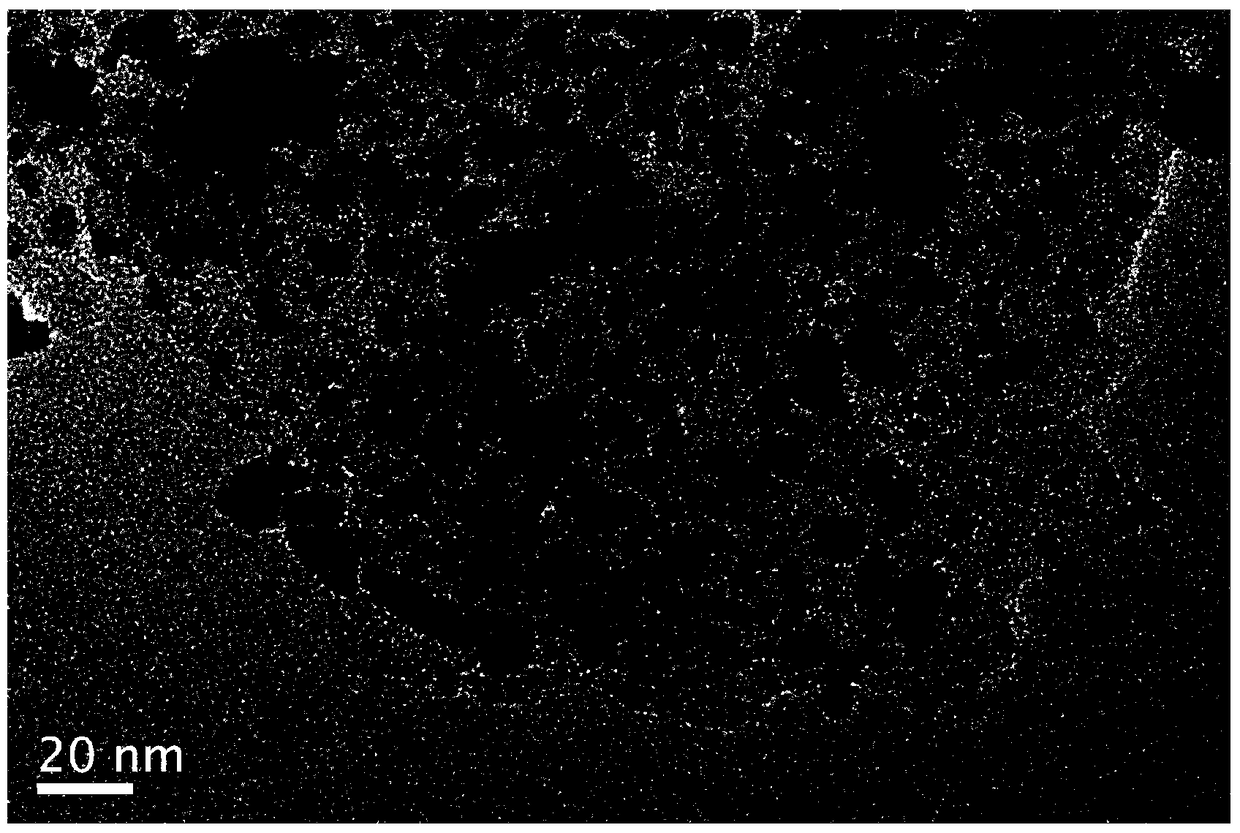

[0032] (2) Put the mixture described in (1) in the crucible and place it in a tube furnace. Put the sample at 800°C, N 2 Calcined under the conditions for 6 hours, to obtain dark brown bulky solid, recorded XRD is porous carbon supported molybdenum carbide (Mo 2 C), showing that the carbide particle size of the sample is about 6nm.

Embodiment 3

[0033] Example 3: Mo supported on porous carbon 2 C

[0034] Synthetic raw materials: glucose, urea, ammonium molybdate

[0035] (1) Weigh 0.03 g glucose, 0.3 g urea and 3 g H 24 Mo 7 N 6 o 24 4H 2 O in a 100 mL beaker, heated and stirred to form a molten state;

[0036] (2) Put the mixture described in (1) in the crucible and place it in a tube furnace. Put the sample at 800°C, N 2 Calcined under the conditions for 6 hours, to obtain dark brown bulky solid, recorded XRD is porous carbon supported molybdenum carbide (Mo 2 C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com