A kind of production method of sulfur-based nitrate nitrogen fertilizer

A production method, nitrate technology, applied in the field of sulfur-based nitrate nitrogen fertilizer production, can solve the problems of inability to produce products with high sulfur content, and achieve the effect of low cost, uniform nutrient content, and direct application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

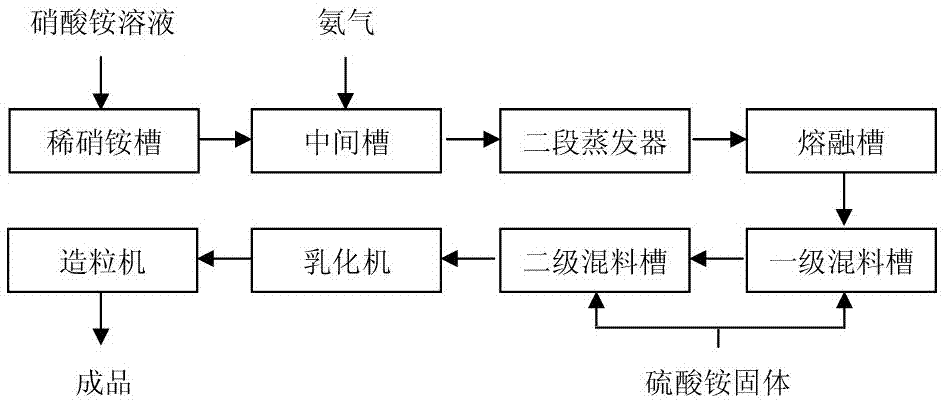

[0025] figure 1 The implementation process flow chart of the present invention is provided, specifically as follows:

[0026] 1. Raw material preparation: 9t of ammonium nitrate, 11t of ammonium sulfate (divided into two parts of 6.6t and 4.4t), spare;

[0027] 2. Dissolve ammonium nitrate (9t) with water (0.8~1.0t) to make a dilute ammonium nitrate solution, pour it into the middle tank on the prilling tower, and pass ammonia gas into the middle tank to adjust the pH value of the dilute ammonium nitrate solution is 7.0, and then pumped into the second-stage evaporator on the prilling tower through an intermediate pump, and treated by the second-stage evaporator to obtain an ammonium nitrate solution with a moisture content of ≤0.5%;

[0028] 3. Send the ammonium nitrate solution with a moisture content of ≤0.5% in step 2 into the melting tank, control the melting temperature at 170-172°C, and put it into the first-level mixing tank, then put 6.6 tons of ammonium sulfate into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com