Foam stabilizer for nitrogen foam combination flooding, foam composition, oil extraction method and application

A nitrogen foam and compound flooding technology, which is applied in the direction of drilling composition, chemical instruments and methods, and production fluids, can solve the problems of foam instability and poor temperature resistance of the foam system, and achieve simple and stable preparation methods Good, simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The foam stabilizing performance of the foam stabilizer at room temperature was determined by high-speed stirring method.

[0030] According to foaming agent (being made up of 0.3% alpha-olefin sodium sulfonate and 0.2% sodium lauryl sulfate by mass concentration) mass concentration is 0.5%, foam stabilizer (by polyanionic cellulose, agar Powder, β-cyclodextrin, sodium tripolyphosphate and triethanolamine are composed according to the mass ratio of 55:7:3:3:2) and the mass concentration is 0.07%, which is prepared into 1000mL of foam composition (being an aqueous solution), pH The value is 6-9, and the preparation method is as follows: mix the raw materials in proportion, stir at 65° C. for 20-35 minutes, mix well, and cool to obtain the foam composition.

[0031] Take 200mL of the above solution in an automatic mixer, stir at high speed (3000rad / min) for 60s, pour the foam into a 1000mL graduated cylinder and read the foam volume as the foam volume. At the same time, ...

Embodiment 2

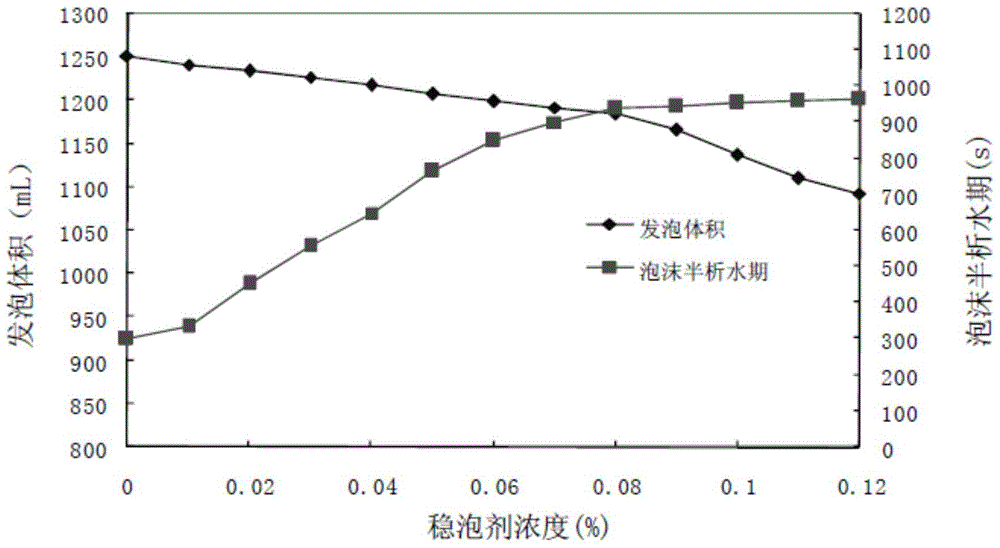

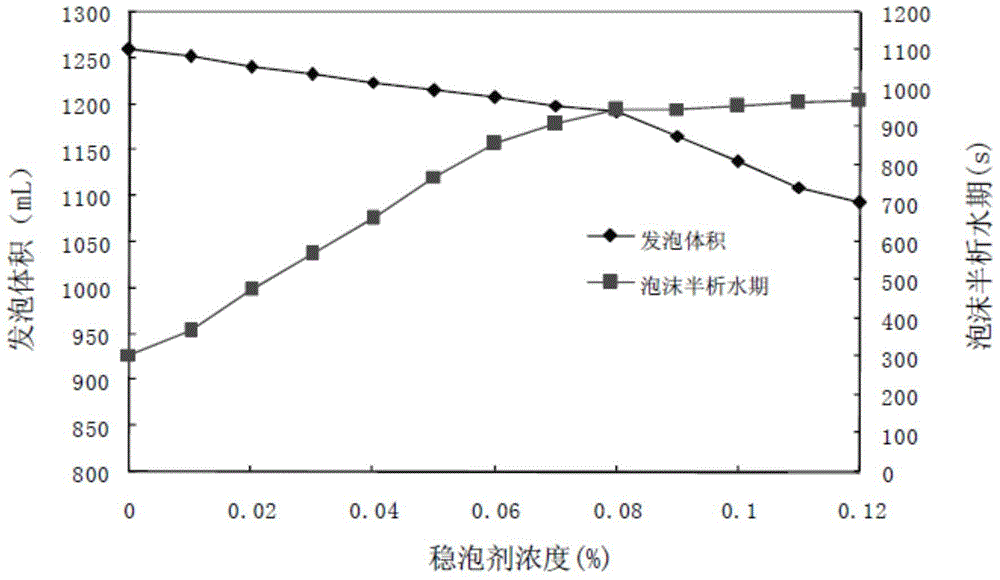

[0036] The foam stabilizing performance of the temperature-resistant foam stabilizer was determined by high-speed stirring method.

[0037] Take 300mL of the foam composition in Example 1 and put it into a high-temperature and high-pressure reaction kettle or a high-temperature-resistant steel cylinder, seal it and put it in a high-temperature thermostat, take it out after keeping the temperature at 120°C for 24 hours, and open the kettle body or a resistant steel cylinder after naturally cooling to room temperature. Take out the sample solution from the high-temperature steel cylinder for later use, take 200mL of the above-mentioned sample solution in an automatic mixer with a measuring cylinder, stir at a high speed (3000rad / min) for 60s, pour the foam into a 1000mL measuring cylinder and read the foam volume, which is the after-temperature resistance foam volume. At the same time, start timing immediately after pouring the foam into the 1000mL measuring cylinder, and record...

Embodiment 3

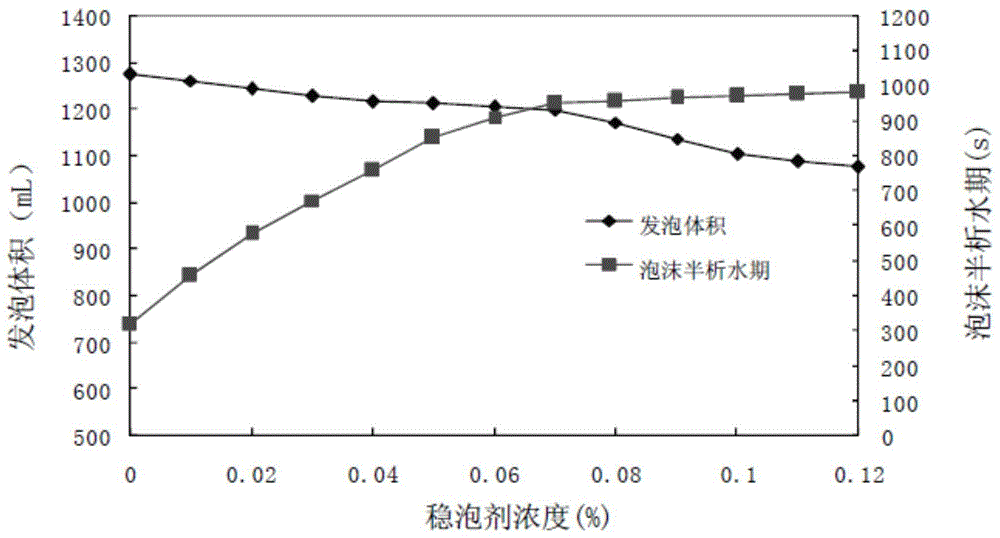

[0042] Concentration comparison of foam stabilizers.

[0043] A foam stabilizer composed of polyanionic cellulose, agar powder, β-cyclodextrin, sodium tripolyphosphate and triethanolamine is used in a mass ratio of 55:7:3:3:2, for foam stabilizers containing different concentrations The foam composition is carried out the test of foaming volume and foam half-water period, and test is carried out at normal temperature, and test method is identical with embodiment 1. Wherein, based on the total mass of the foam composition, the mass concentration range of the foam stabilizer is 0.01%-0.12%, and the blowing agent (by mass concentration is 0.3% alpha-olefin sodium and mass concentration is 0.2% ten Dialkyl sodium sulfate) mass concentration is 0.5%, the pH value of the foam composition is 6-9, and the preparation method of the foam composition is the same as that in Example 1. The experimental results are shown in Table 3.

[0044] The impact of table 3 foam stabilizer concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com