Method for leaching zinc in oxidation-sulfidation mixed zinc ore through ammonium chloride solution at high temperature and oxygen pressure

A technology of ammonium chloride solution and oxygen pressure leaching, which is applied in the field of leaching zinc from oxidation-sulfide mixed ore, which can solve the problems of low leaching efficiency and difficulty in handling zinc oxide ore, zinc sulfide ore, etc., to achieve inhibition of dissolution and improvement of binding capacity , the effect of enhanced binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

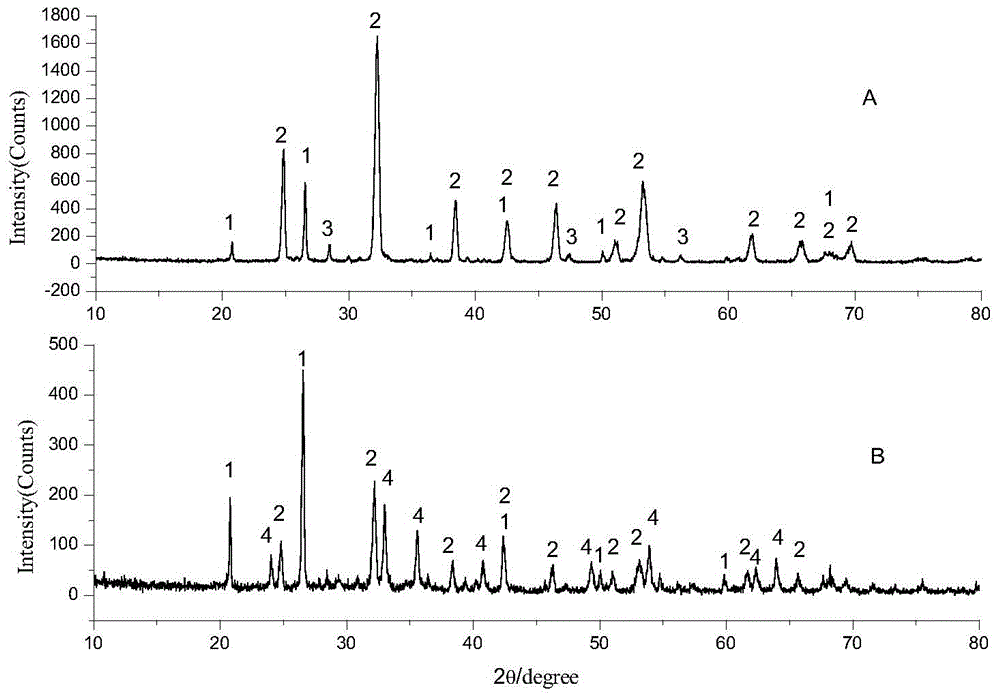

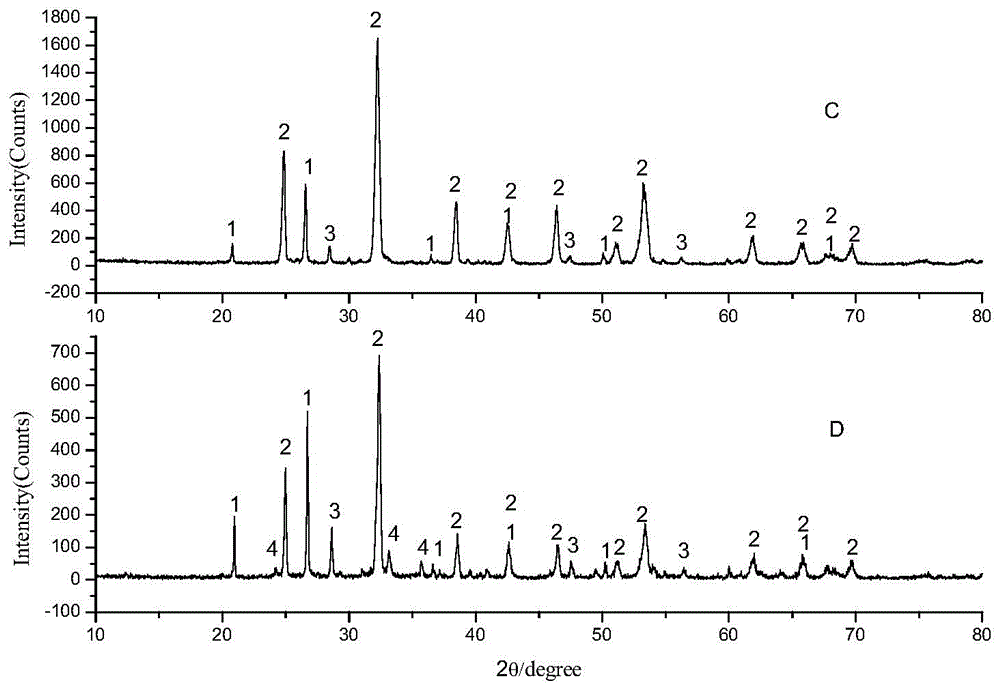

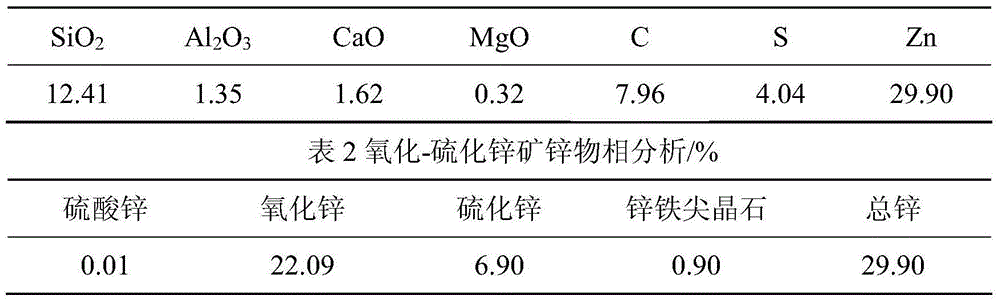

[0020] Take 100g of an oxidized-sulfurized mixed zinc ore (its composition is shown in Table 1 and its phase is shown in Table 2), mix 5mol / L ammonium chloride solution as a leaching agent, and add them together at a liquid-solid ratio of 5:1mL / g In the autoclave, the stirring speed is 300r / min, the oxygen partial pressure is 1.4Mpa, and the leaching time is 2h at a temperature of 135°C, and the leaching rate of zinc is 95.31%. figure 1 (A) and (B) are the XRD patterns of the raw ore and leaching residue at 135°C respectively. figure 1 It can be seen that the gangue impurities in the leaching slag are mainly SiO 2 , Fe 2 o 3 form exists.

[0021] Table 1 Analysis of chemical composition of oxide-zinc sulfide ore / %

[0022]

Embodiment 2

[0027] Take 100g of an oxidized-sulfurized mixed zinc ore (its composition is shown in Table 1 and its phase is shown in Table 2), mix 6mol / L ammonium chloride solution as a leaching agent, and add them together at a liquid-solid ratio of 10:1mL / g In the autoclave, the stirring speed is 300r / min, the oxygen partial pressure is 1.0Mpa, the leaching time is 3.0h at a temperature of 155°C, and the leaching rate of zinc is 97.37%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com