Agaric cookies and preparation method thereof

A fungus and raw material technology, applied in the field of food processing, can solve the problems of no obvious improvement in nutrition and health care, unclear surface texture of cookies, high cholesterol, etc., to improve nutrition and health care effects, retain unique flavor, and taste crunchy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

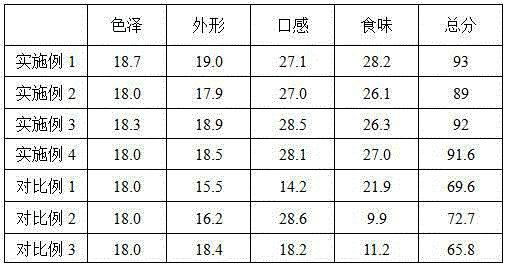

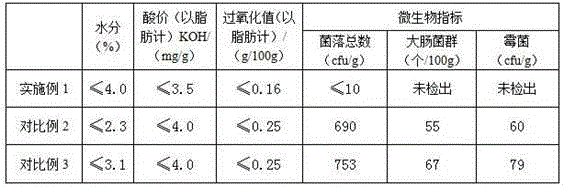

Embodiment 1

[0031] A fungus cookie, the raw materials are: 350 parts of low-gluten flour, 100 parts of whole fungus powder, 28 parts of water chestnut powder, 180 parts of safflower oil, 70 parts of butter, 100 parts of white sugar, 150 parts of egg yolk, and 120 parts of light cream , 4 parts of gluconolactone, 2 parts of sodium caseinate.

[0032] The preparation method of the whole fungus powder used in the above-mentioned raw materials is:

[0033] (1) Add the dried fungus into the magnesium carbonate aqueous solution with a mass fraction of 0.01% at 15°C according to the mass ratio of 1:20 and soak for 20 minutes, remove and wash, then add the mass fraction at 20°C according to the mass ratio of 1:30 Soak hair for 15% calcium acetate aqueous solution, and finally use vacuum freeze dryer to dehydrate;

[0034] (2) Crush the dehydrated fungus and pass through a 160-mesh sieve to get the whole fungus powder.

[0035] The preparation method of fungus cookies is:

[0036] (1) Stir the ...

Embodiment 2

[0042] A kind of fungus cookie, the raw materials are: 350 parts of low-gluten wheat flour, 76 parts of whole fungus powder, 25 parts of water chestnut powder, 150 parts of safflower seed oil, 75 parts of butter, 80 parts of white sugar, 150 parts of egg yolk, and 100 parts of light cream , 3 parts of gluconolactone, 3 parts of sodium caseinate.

[0043] The preparation method of whole fungus powder and fungus cookie is the same as in Example 1.

Embodiment 3

[0045] A fungus cookie, the raw materials are: 370 parts of low-gluten wheat flour, 85 parts of whole fungus powder, 20 parts of water chestnut powder, 165 parts of safflower oil, 60 parts of butter, 91 parts of white sugar, 170 parts of egg yolk, and 112 parts of light cream , 5 parts of gluconolactone, 2 parts of sodium caseinate.

[0046] The preparation method of whole fungus powder and fungus cookie is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com