Alginate dressing containing composite silver-zinc antibacterial agents and preparation method thereof

The technology of antibacterial agent and alginate is applied in the field of alginate dressing containing composite silver-zinc antibacterial agent and its preparation field, and can solve the problems of low silver-containing concentration, increased process, labor and time cost, limitation of antibacterial performance, and the like, Achieve the effect of strong bactericidal ability, good formula stability and high antibacterial and bactericidal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a kind of preparation method of the above-mentioned alginate dressing containing composite silver-zinc antibacterial agent, comprising the following steps:

[0037] (1) Preparation of composite silver-zinc antibacterial agent: take silver compound, zinc compound and inert carrier, mix the three evenly, and place them in a porcelain dish; then put them into a high-temperature furnace and burn them at 1000°C for 3 hours; 200 mesh sieve, take the under-sieve, mix evenly, and obtain the composite silver-zinc antibacterial agent;

[0038] (2) Preparation of alginate solution: Soak alginate at 30°C-40°C for 2h-3h to pre-dissolve, then stir at a temperature of 40°C-60°C and a speed of 200r / min-400r / min Stir for 3h-4h or at a temperature of 30°C-60°C and a speed of 200r / min-400r / min for 4h-7h, and finally filter with a filter cloth under a pressure of 2-3kg to obtain the alginate solution;

[0039] (3) Preparation of spinning stock solution:...

Embodiment 1-6

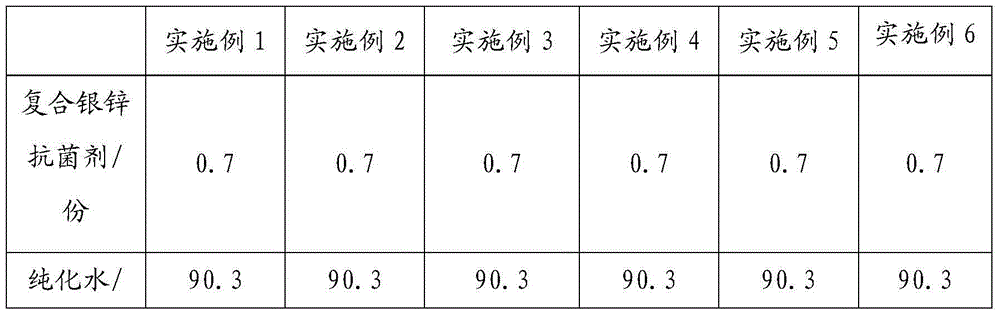

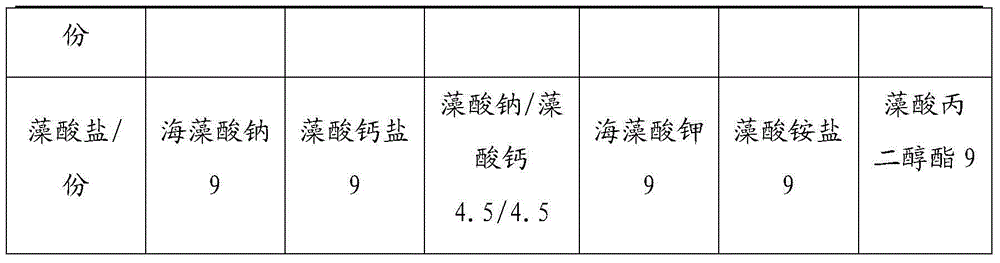

[0054] The proportioning of specific embodiments of the present invention is shown in Table 1.

[0055] The following raw materials are taken in parts by weight: 0.4-1.4 parts of composite antibacterial powder; 84.6-95.6 parts of purified water; 4-14 parts of alginate. Wherein, in the composite antibacterial powder used in Examples 1-6, the mass fraction of nano silver in the composite antibacterial powder is 20%, and the mass fraction of nano zinc in the composite antibacterial powder is 40%.

[0056] Table 1 The proportioning table of Embodiment 1-6

[0057]

[0058]

[0059] The above-mentioned raw materials are prepared according to the following steps to contain the alginate dressing of compound silver-zinc antibacterial agent, and it comprises the following steps successively:

[0060] (1) Preparation of composite silver-zinc antibacterial agent: take silver compound, zinc compound and inert carrier, mix the three evenly, and place them in a porcelain dish; then p...

Embodiment 7-16

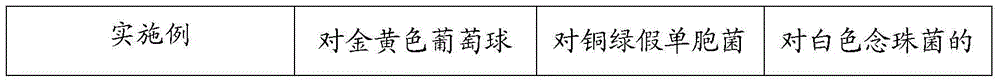

[0073] Studies have found that when the ratio of nano-silver and nano-zinc is within a certain range, their bactericidal effect will increase synergistically. Below, under the raw material proportioning of embodiment 2, observe the influence that the alginate fiber dressing containing different proportioning nano-silver and nano-zinc has antibacterial and bactericidal effect on Staphylococcus aureus, Pseudomonas aeruginosa, Candida albicans , the results are shown in Table 3.

[0074] Table 3: Effects of different ratios of nano-silver and nano-zinc on the bactericidal rate of alginate fiber dressings

[0075]

[0076] As can be seen from Table 3, the alginate dressing containing the composite silver-zinc antibacterial agent of the present invention has a strong antibacterial and bactericidal effect on Staphylococcus aureus, Pseudomonas aeruginosa, and Candida albicans, and the bactericidal effect can reach more than 95%. And when nano-silver accounts for 20% in the weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Colony count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com