Carbon nano-tube film composite material preparation method

A technology of carbon nanotube film and composite material, which is applied in the field of preparation of carbon nanotube film composite material, can solve the problems of poor mechanical strength and toughness, no formation, composite material voids and bubbles, etc., to improve interface performance and reduce defects , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

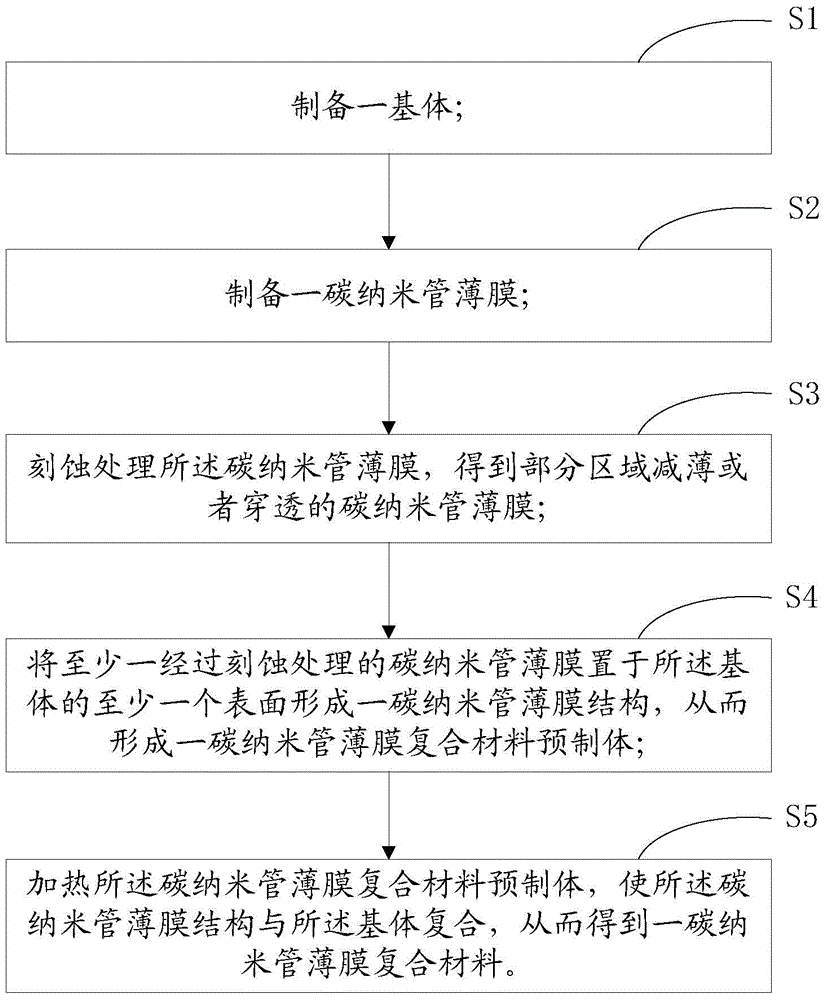

[0031] ginseng figure 1 , a method for preparing a carbon nanotube thin film composite material in one embodiment of the present invention comprises the following steps:

[0032] S1. Prepare a matrix. The matrix is a polymer matrix.

[0033] S2. Prepare a carbon nanotube film. The carbon nanotube film is prepared by a floating catalytic method or a spinnable array film drawing method, or is a film-like carbon nanotube prepared by directly using a bucky paper carbon nanotube film or other methods. In this embodiment, the floating catalytic method is preferably used, and the prepared carbon nanotube film has a three-dimensional network structure.

[0034] S3. Etching the carbon nanotube film to obtain a thinned or penetrated carbon nanotube film in some regions.

[0035] First, the carbon nanotube film is treated with an organic solvent to form a densified carbon nanotube film, and then the densified carbon nanotube film is etched. The organic solvent is a volatile organic...

Embodiment 1

[0047] In this embodiment, the composite material matrix is an epoxy resin polymer matrix, the epoxy resin solution uses acetone as a solvent, and the epoxy resin concentration is 10%.

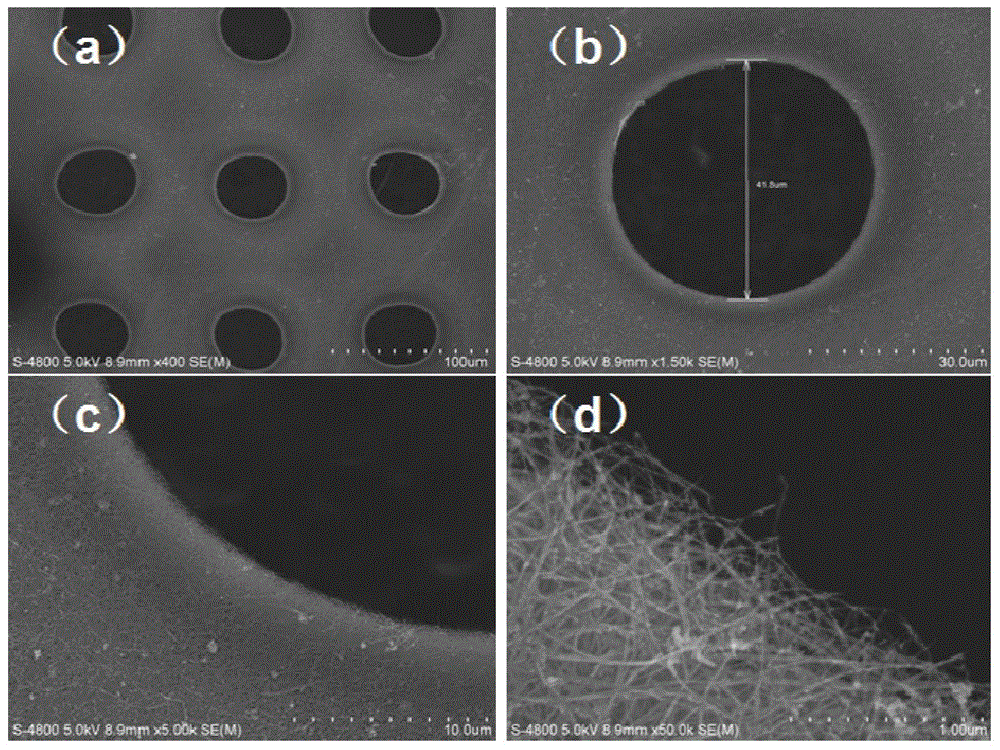

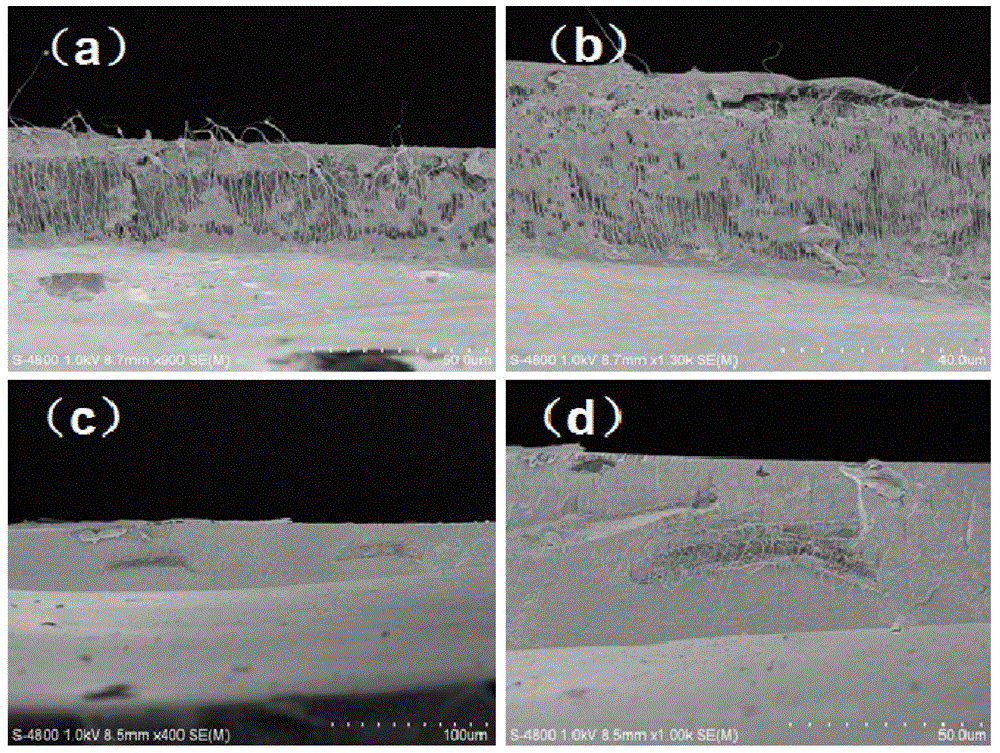

[0048] In this example, the three-dimensional network structure carbon nanotube film prepared by floating catalytic method has a thickness of 15 μm (densified with ethanol solution). First, the carbon nanotube film is processed by laser etching, the carbon nanotube film is completely spread on the upper surface of the stage, the film is fixed around the film, so that the carbon nanotube film is on a plane, and the laser emission point is adjusted. The relative position of the stage is such that the focus of the laser is formed on the upper surface of the carbon nanotube film; when the current intensity of the laser is adjusted to 3A, the diameter of the thinning cavity of the carbon nanotube film is about 50 μm, and the When the table is not moving, the control software is used to adjust the...

Embodiment 2

[0052] In this embodiment, the composite material matrix is a phenolic resin polymer matrix, the phenolic resin solution uses acetone as a solvent, and the concentration of the phenolic resin is 10%.

[0053] In this example, the three-dimensional network structure carbon nanotube film prepared by floating catalytic method has a thickness of 15 μm (densified with acetone solution). First, the carbon nanotube film is processed by laser etching, the carbon nanotube film is completely spread on the upper surface of the stage, the film is fixed around the film, so that the carbon nanotube film is on a plane, and the laser emission point is adjusted. The relative position of the stage so that the focus of the laser is formed on the upper surface of the carbon nanotube film; When the object stage is not moving, the control software is used to adjust the laser focus position on the surface of the carbon nanotube film, specifically, (the distance between the focus points is 200 μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com