Double-liquid-phase fermentation method of red koji citraurin by coupled in-situ fermentation-extraction

An orange pigment and two-liquid phase technology, applied in the field of fermentation engineering, can solve the problems of low production level of orange pigment, inability to achieve industrialized production, and long fermentation time, and achieve the effects of shortening fermentation time, reducing conversion, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

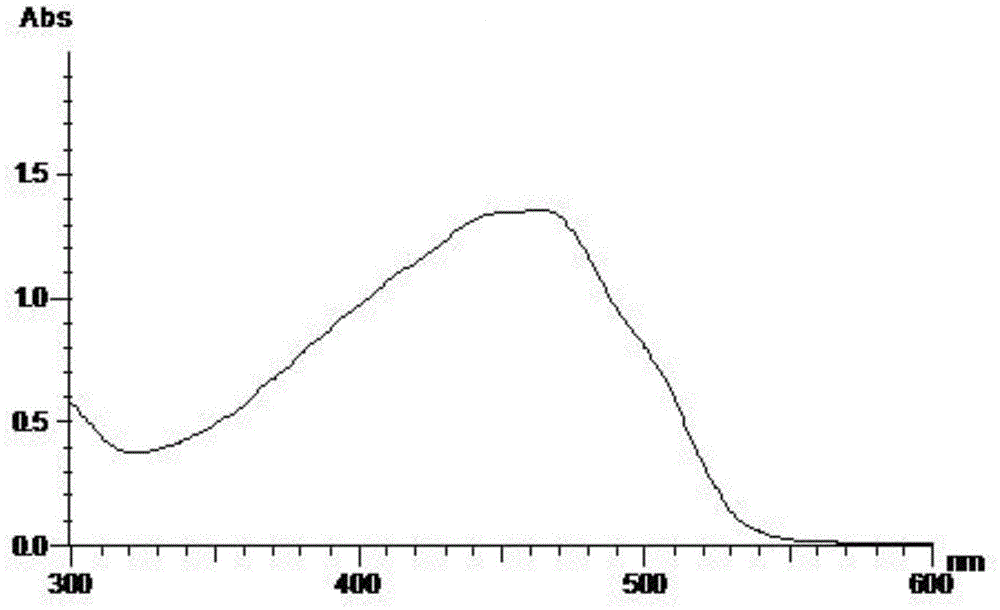

Image

Examples

Embodiment 1

[0031] The species of Monascus is Monascus sp. JJLY-4A (Monascus sp.JJLY-4A), and the fermentation medium is prepared according to the following ratio. Basic medium (g / L): tapioca starch 30, ammonium sulfate 10, NaNO 3 6. Yeast extract 0.5, corn steep liquor powder 0.5, magnesium sulfate 1, potassium dihydrogen phosphate 1; extract phase (volume ratio of basic medium): soybean oil 5%, corn oil 8%, dicaprylic glyceride 2%. Except for soybean oil and corn oil in the extraction phase, the rest of the glycerides were added to the medium 24 hours after the fermentation started.

[0032] The liquid seeds of Monascus in the logarithmic growth phase were placed in a 500mL Erlenmeyer flask containing 100mL of fermentation medium at an inoculation volume of 6% by volume, and the shake flask was fermented at a speed of 180r / min and a temperature of 30°C. 4d. After the end, the color value of Monascus orange pigment was measured to be 200-210U / mL (converted to the basic medium volume). ...

Embodiment 2

[0034]Monascus JJLY-4A was used as shake flask fermentation strain. The steps of the strain cultivation and fermentation process in Example 1 above are the same, the difference is that the fermentation medium is prepared according to the following ratio, basic medium (g / L): tapioca starch 60, ammonium sulfate 10, NaNO 3 6. Yeast extract 0.5, corn steep liquor powder 0.5, magnesium sulfate 1, potassium dihydrogen phosphate 1; extract phase (volume ratio of basic medium): soybean oil 5%, corn oil 8%, dicaprylic glyceride 2%. Except for soybean oil and corn oil in the extraction phase, the rest of the glycerides were added to the medium 48 hours after the fermentation started.

[0035] The liquid seeds of Monascus in the logarithmic growth phase were placed in a 500mL Erlenmeyer flask containing 100mL of fermentation medium at an inoculation volume of 6% by volume, and the shake flask was fermented at a speed of 180r / min and a temperature of 30°C. 5d. After the end, the color v...

Embodiment 3

[0037] The steps of the strain cultivation and fermentation process were the same as those in Example 1 above, except that Monascus sp. 9903 was used as the shake flask fermentation strain. The fermentation medium is prepared according to the following ratio, basic medium (g / L): tapioca starch 60, ammonium sulfate 5, NaNO 3 5. Yeast extract 5, corn steep liquor powder 5, magnesium sulfate 1, potassium dihydrogen phosphate 1; extract phase (accounting for the volume ratio of the basic medium): soybean oil 5%, corn oil 8%, dicaprylic glyceride 2%. Except for soybean oil and corn oil in the extraction phase, other glyceride substances were added to the medium 24 hours after the fermentation started.

[0038] The liquid seeds of Monascus in the logarithmic growth phase were placed in a 500mL Erlenmeyer flask containing 100mL of fermentation medium at an inoculum volume of 8% by volume, and the shake flask was fermented at a speed of 180r / min and a temperature of 30°C. 5d. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com