Method for preparing silver antimony telluride thermoelectric material by taking binary tellurides as start raw materials

A technology of silver antimony telluride and thermoelectric materials, which is applied in the directions of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc. Complex operation steps and other problems, to achieve the effect of easy realization of preparation conditions, easy preparation time and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

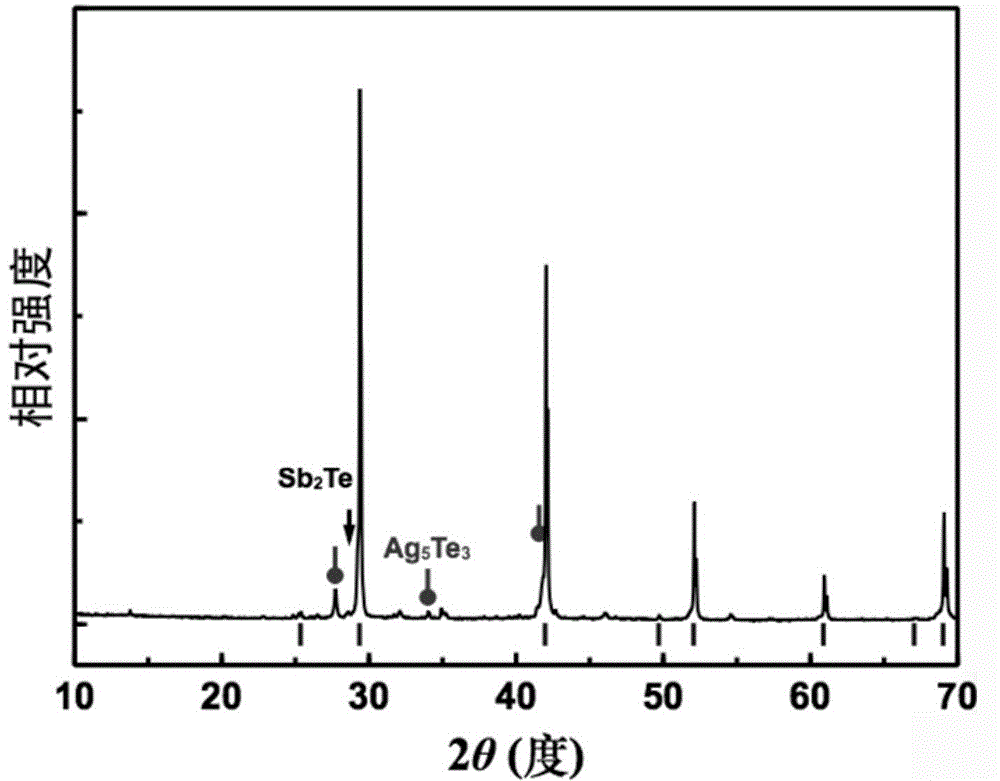

Embodiment 1

[0031] A method for preparing a silver antimony telluride thermoelectric material using binary telluride as a starting material comprises the following steps:

[0032] 1) Ingredients: According to the silver telluride-antimony telluride pseudo-binary phase diagram, silver telluride and antimony telluride are weighed as starting materials according to the molar ratio of 1:1 (equivalent to (50-x):(50+x ) in the ratio of x=0, the amount of the starting material corresponds to the strictly stoichiometric silver antimony telluride compound), wherein the mass purity of silver telluride is better than 99.99%; the mass purity of antimony telluride is better than 99.999%; Both tellurides are in powder form, with a particle size of less than 200 mesh;

[0033] 2) Briquetting sealing: put the starting material described in step 1) into an agate mortar, fully grind it for 60 minutes under an air atmosphere, and then press it into several cylindrical blocks with a diameter of 12.7 mm and a...

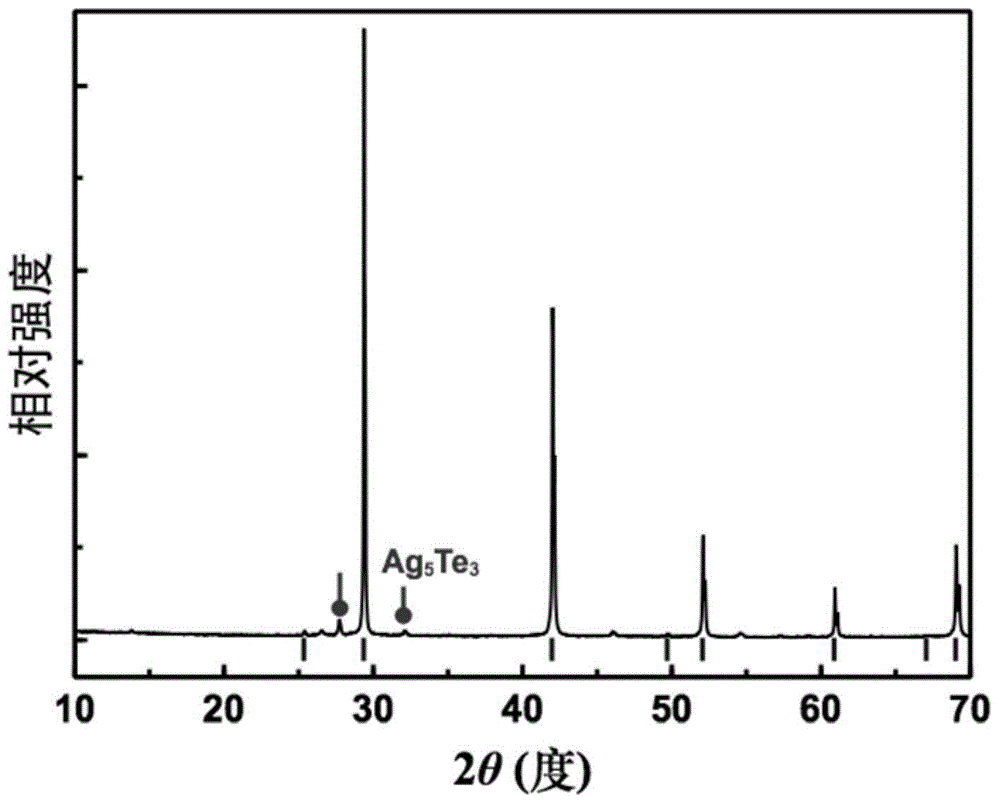

Embodiment 2

[0040] A method for preparing a silver antimony telluride thermoelectric material using binary telluride as a starting material comprises the following steps:

[0041] 1) Ingredients: silver telluride and antimony telluride are weighed as starting materials according to the molar ratio of 48:52 (equivalent to x=2 in the ratio of (50-x):(50+x)), wherein, silver telluride The mass purity is better than 99.99%, and the mass purity of antimony telluride is better than 99.999%. Both tellurides are in powder form, and the particle size is below 200 mesh;

[0042] 2) Briquetting and sealing: put the raw materials in step 1) into an agate mortar, fully grind them for 60 minutes in an air atmosphere, and then press them into several cylindrical blocks with a diameter of 12.7 mm and a height of about 3 mm on a tablet press. The density of the obtained block is about 82% of the density of silver antimony telluride; the obtained block is placed in a quartz tube with a diameter of 15 mm an...

Embodiment 3

[0048] A method for preparing a silver antimony telluride thermoelectric material using binary telluride as a starting material comprises the following steps:

[0049] 1) Ingredients: Silver telluride and antimony telluride are weighed as starting materials according to the molar ratio of 44:56 (equivalent to x=6 in the ratio of (50-x):(50+x), wherein the mass of silver telluride The purity is better than 99.99%, and the mass purity of antimony telluride is better than 99.999%. Both tellurides are in powder form, and the particle size is below 200 mesh;

[0050] 2) Briquetting seal: Put the raw materials in step 1) into an agate mortar, grind them fully for 30 minutes under air atmosphere, and then press them into several cylindrical blocks with a diameter of 12.7 mm and a height of about 3.5 mm on a tablet press , the density of the obtained block is about 73% of the density of silver antimony telluride; the obtained block is put into a quartz tube with a diameter of 15 mm an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com