Classified ore dressing method of calcareous and siliceous mixed type stone coal vanadium ore

A mineral processing method and a mixed technology, applied in flotation, solid separation, grain processing, etc., can solve the problems of low recovery rate of vanadium mineral processing, large dosage of chemicals, waste of resources, etc., to reduce the amount of mineral dressing chemicals, reduce the amount, reduce The effect of alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

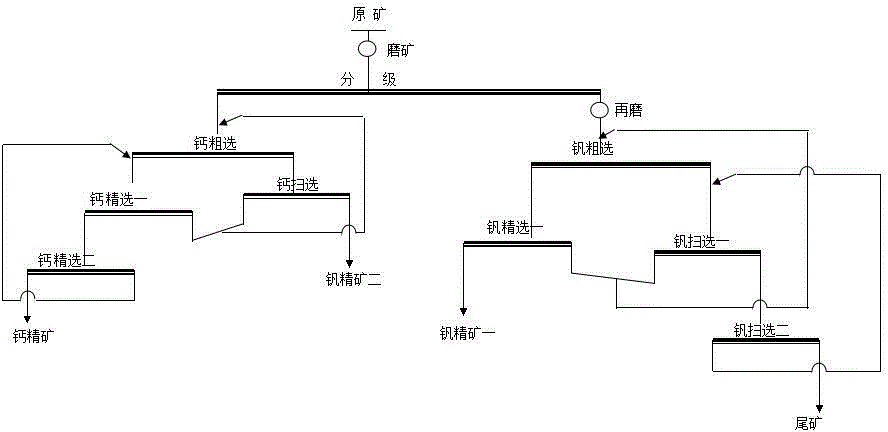

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with embodiments.

[0026]This embodiment provides a classification ore dressing method for calcareous and siliceous mixed vein type stone coal vanadium ore. The original ore is a vanadium mine in Hubei Province. It is a low-grade stone coal vanadium ore with mixed veins of calcareous and siliceous. The recyclable valuable components in the ore are mainly vanadium pentoxide. The content of vanadium pentoxide in the ore is 0.83%, the production cost of direct smelting of raw ore to extract vanadium is extremely high, and the recovery rate is only about 30%, making it difficult for enterprises to make profits. The invention aims at the process of using ore dressing to enrich vanadium pentoxide to provide high-quality vanadium concentrate for smelting and extracting vanadium.

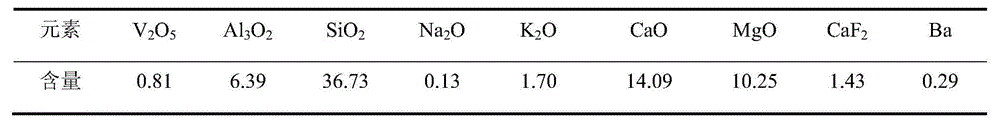

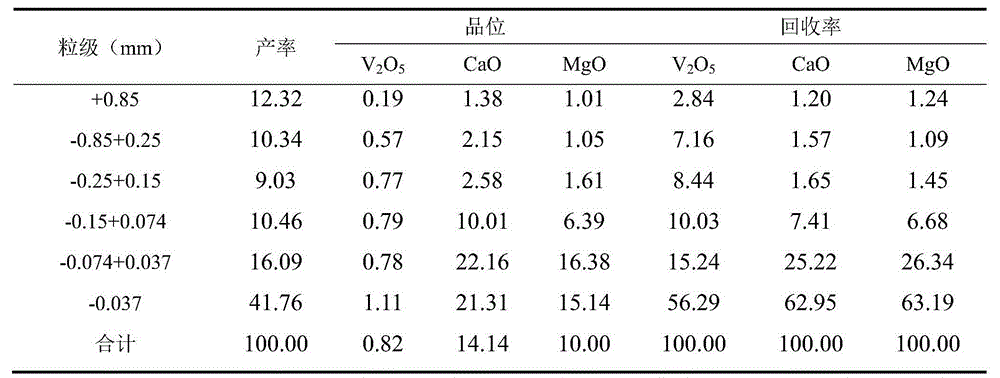

[0027] The mineral composition of the raw ore is: quartz minerals account for 25.66%, mica (including vanadium-containing minera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com