Manufacturing method for orthopaedics implant odd-shaped part

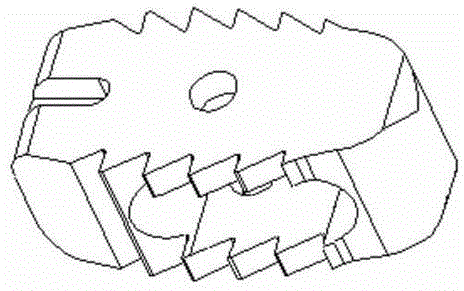

A technology for orthopedic implants and special-shaped parts, which is applied in the preparation of special-shaped parts of orthopedic implants, metal powder injection molding technology to prepare special-shaped parts of titanium alloy orthopedic implants, and can solve the problems of difficult automatic batch production, material composition segregation, To solve the problems of high preparation cost, achieve the effect of ensuring density and surface finish, good biomechanical properties, and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of the orthopedic implant special-shaped part of the present invention, the orthopedic implant special-shaped part can be used for the spine, that is, the internal fixation of the spinal column orthopedic implant special-shaped part, the method comprises the following steps:

[0034] (1) Feed preparation: the raw material powder is TC4 titanium alloy atomized powder, with an average particle size of 2 μm, and the binder is composed of 40% polypropylene, 20% vegetable oil, 5% plasticizer and 35% paraffin (by mass percentage count). Mix the binder with TC4 titanium alloy atomized powder, the volume fraction of the binder in the obtained mixture is 43%, and the rest is TC4 titanium alloy atomized powder, put the mixture into the kneader, knead at 120°C for 2 hours, After cooling, it is crushed and granulated to obtain uniform granular feed with good fluidity.

[0035] (2) Injection molding: feed the granular feed into the injection machine and feed it...

Embodiment 2

[0042] A method for preparing the special-shaped orthopedic implant of the present invention, the special-shaped orthopedic implant can be used for the spine, the method comprises the following steps:

[0043] (1) Feed preparation: The raw material powder is TC4 titanium alloy atomized powder, the average particle size is 10 μm, and the binder is composed of 35% polypropylene, 15% vegetable oil, 10% plasticizer, 35% paraffin and 5% micro Crystal wax composition (by mass percentage). Mix the binder with TC4 titanium alloy atomized powder, the volume fraction of the binder in the resulting mixture is 50%, put the mixture into the kneader, knead at 135°C for 1 hour, crush and granulate after cooling, and obtain fluidity Good even granular feeding.

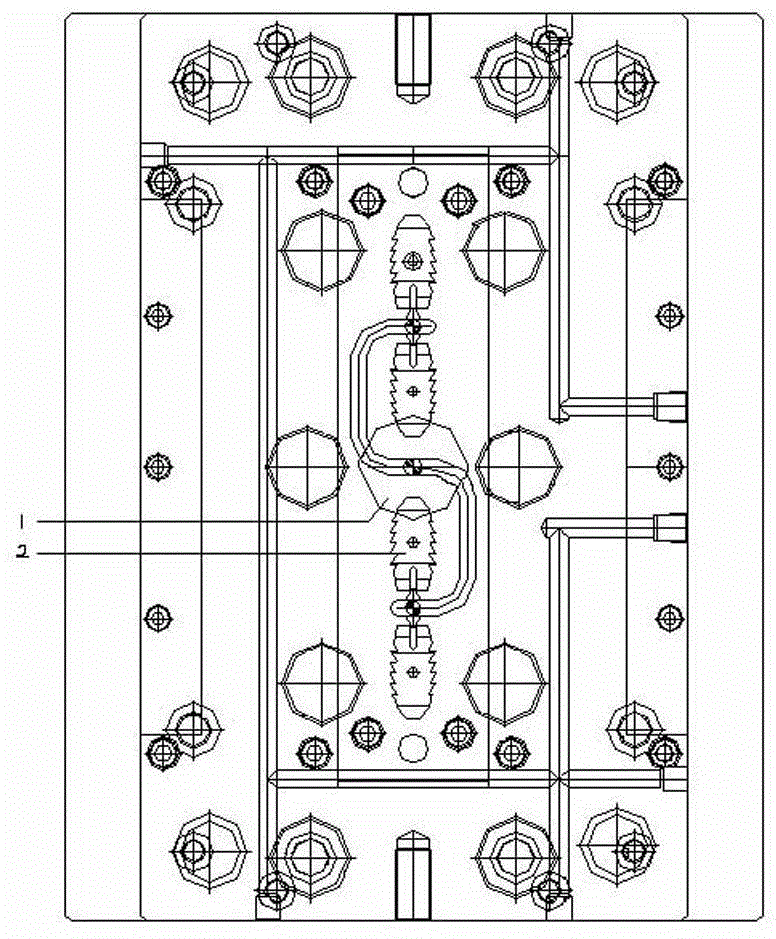

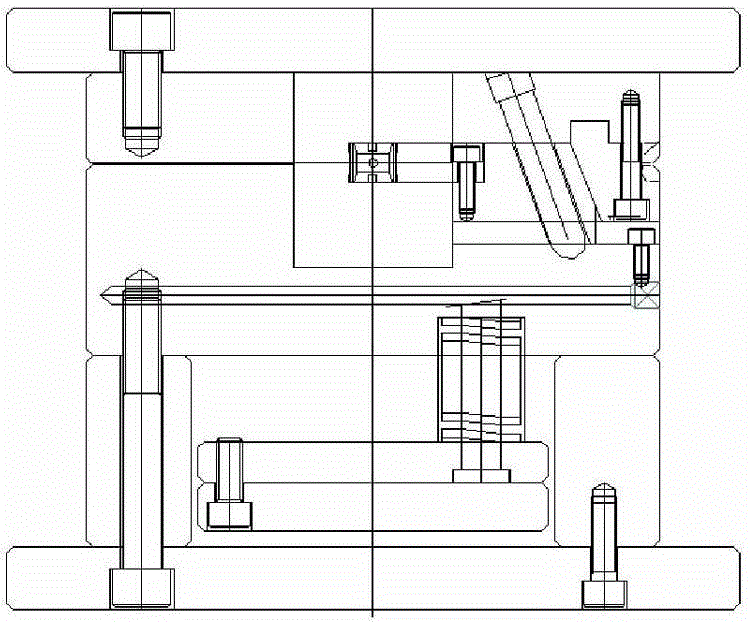

[0044] (2) Injection molding: feed the granular feed into the injection machine and feed it to the mold (see figure 1 and figure 2 ), the injection temperature is 170°C, the injection pressure is 13MPa, and the injection rate is 7...

Embodiment 3

[0050] A method for preparing the special-shaped orthopedic implant of the present invention, the special-shaped orthopedic implant can be used for the spine, the method comprises the following steps:

[0051] (1) Feed preparation: The raw material powder is TC4 titanium alloy atomized powder, with an average particle size of 10 μm, and the binder is composed of 35% polypropylene, 15% vegetable oil, 10% plasticizer and 40% paraffin (by mass percentage count). Mix the binder with TC4 titanium alloy atomized powder, the volume fraction of the binder in the resulting mixture is 48%, put the mixture into the kneader, knead at 120°C for 2 hours, crush and granulate after cooling, and obtain fluidity Good even granular feeding.

[0052] (2) Injection molding: feed the granular feed into the injection machine and feed it to the mold (see figure 1 and figure 2 ) for injection, the injection temperature is 175°C, the injection pressure is 12MPa, and the injection rate is 55% of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com