Calcium magnesium phosphate nanometer structure material and preparation method thereof

A calcium-magnesium phosphate, nano-structure technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of difficult control of size and morphology, easy crystal growth, etc., and achieves convenient operation and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] (1) The preparation process of the present invention is simple, easy to operate, does not require complicated and expensive equipment, and is easy to realize industrialized production;

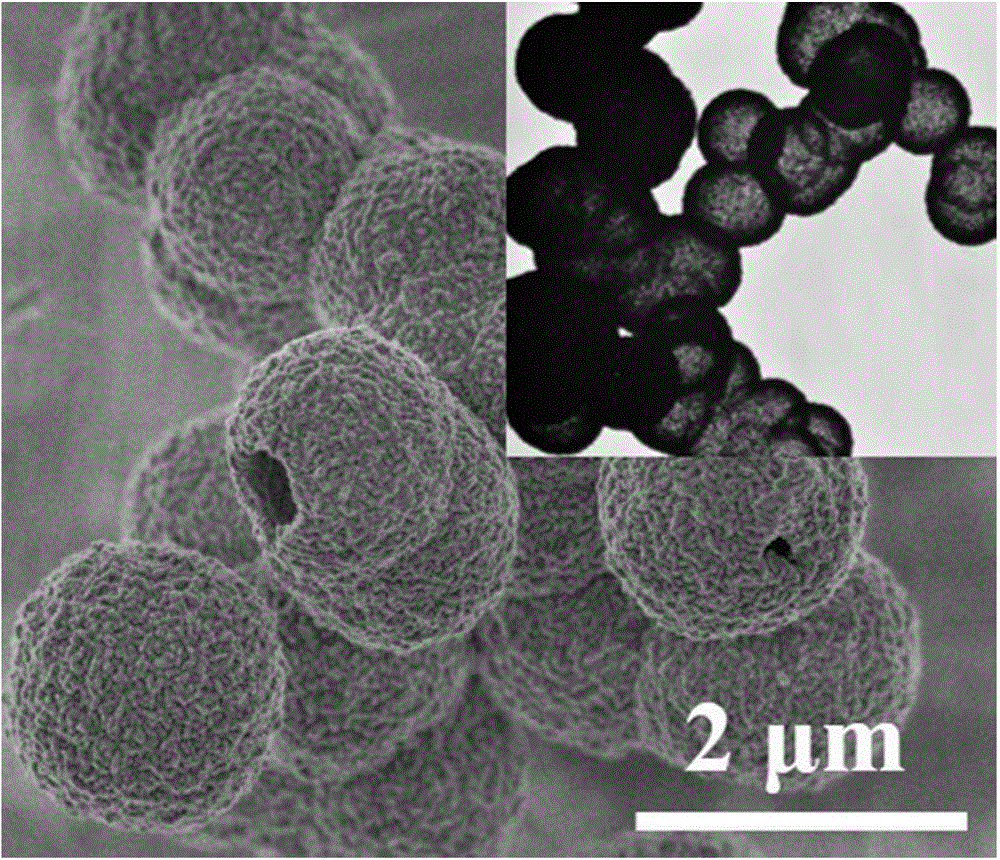

[0043] (2) Prepared hydroxyapatite nanorods / nanosheets assembled hollow microspheres and monetite nanoparticles assembled hollow microspheres with regular morphology (see Figure 2 ~ Figure 4 ), the diameter of the hollow microspheres is about 1 to 2 microns, and the diameter of the cavity can be 200 nanometers to 1.5 microns;

[0044] (3) The prepared amorphous calcium magnesium phosphate submicron solid microspheres have regular morphology and relatively uniform size (see Figure 5 ~ Figure 8 ), the diameter is about 0.5-1 micron; the thickness of the prepared magnesium phosphate pentahydrate nanosheet can be 10-50 nanometers;

[0045] (4) The phase and morphology of the obtained calcium magnesium phosphate nanostructure can be adjusted by changing the molar ratio of calcium ions to magnesiu...

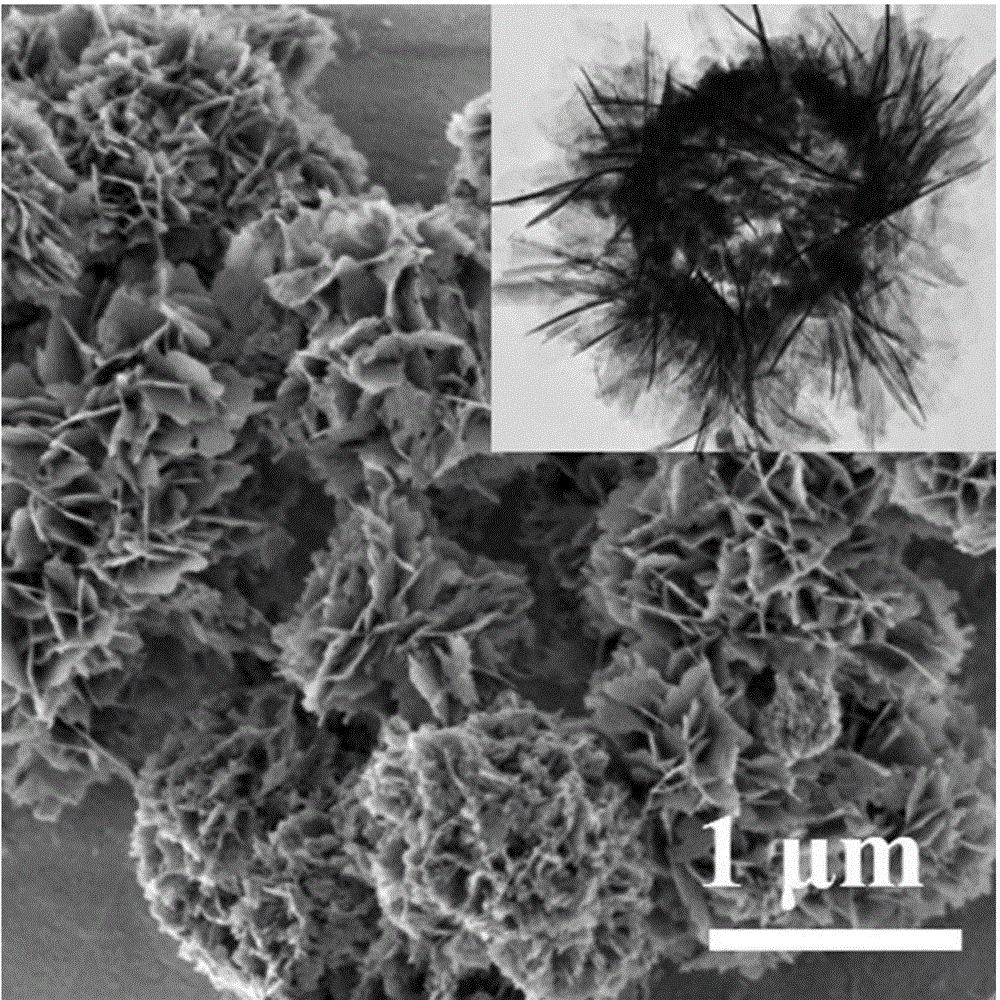

Embodiment 1

[0049] At room temperature, add 1.110 grams of CaCl 2 Dissolve in 100 ml of deionized water to form a solution A, add 2.033 g of MgCl 2 ·6H 2 O was dissolved in 100 ml of deionized water to form solution B, and 1.570 g of creatine phosphate sodium salt was dissolved in 80 ml of deionized water to form solution C. Take 20 ml of deionized water and 9 ml of A solution, 1 ml of B solution and 10 ml of C solution and mix under magnetic stirring to form a clear mixed solution. Transfer the clear mixed solution to a microwave reactor (60 ml capacity) and seal , Microwave heating to 120°C and keeping it for 10 minutes. After the reaction system was naturally cooled to room temperature, the product was taken out and centrifuged. The separated product was washed 3 times with deionized water, washed once with absolute ethanol, and dried in the air at 60°C to obtain a nanosheet assembled hollow microsphere structure. The diameter is about 1 micron. The phase of the hollow microspheres is ...

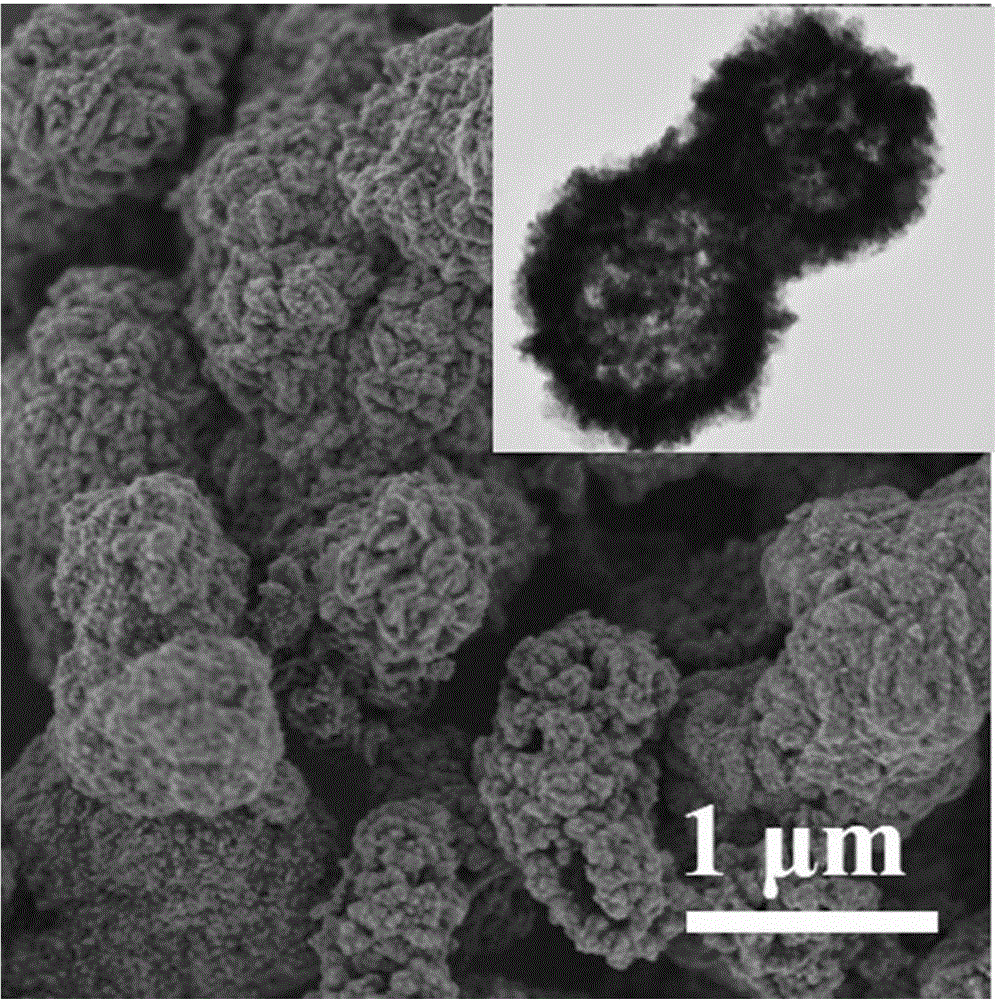

Embodiment 2

[0051] At room temperature, add 1.110 grams of CaCl 2 Dissolve in 100 ml of deionized water to form a solution A, add 2.033 g of MgCl 2 ·6H 2 O was dissolved in 100 ml of deionized water to form solution B, and 1.570 g of creatine phosphate sodium salt was dissolved in 80 ml of deionized water to form solution C. Take 20 ml of deionized water and 7 ml of A solution, 3 ml of B solution and 10 ml of C solution and mix under magnetic stirring to form a clear mixed solution. Transfer the clear mixed solution into a microwave reactor (60 ml capacity) and seal , Microwave heating to 120°C and keeping it for 10 minutes. After the reaction system was naturally cooled to room temperature, the product was taken out and centrifuged. The separated product was washed 3 times with deionized water, washed once with absolute ethanol, and dried in air at 60°C to obtain nanoparticle assembly hollow microspheres. About 1 micron. The phase of the hollow microspheres is the monetite phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com