Anaerobic ammonia oxidation reactor device

An anammox and reactor technology, applied in anaerobic digestion treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of low treatment efficiency, sludge loss, slow proliferation rate of anammox bacteria, etc. , to achieve the effect of slowing down pollution, reducing deposition and delaying membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

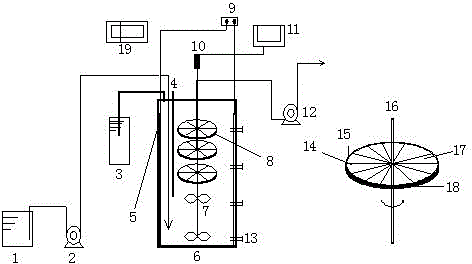

[0021] The device structure of the present invention includes: water storage tank, water inlet pump, water sealing device, constant temperature device, graphite electrode, anaerobic ammonium oxidation reactor, stirring paddle, flat membrane module, DC power supply, stirring rotating motor, AC power supply, membrane module Product water pump, sampling port, flow channel of flat membrane module, sealing ring, product water pipe, flat membrane, flow channel support plate, PLC control.

[0022] Its specific implementation process is:

[0023] The waste water is pumped into the anaerobic ammonium oxidation reactor through the water inlet pump storage tank. The anaerobic ammonium oxidation reactor is equipped with a water seal to ensure the anaerobic environment of the system, and a constant temperature device is also installed to maintain the reaction of the activated sludge at about 30°C. The anaerobic ammonium oxidation reactor is equipped with cathode and anode graphite plates,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com