A kind of preparation method of antimony

A technology of antimony trichloride and rectification, applied in the field of metallurgical purification, can solve the problems of high equipment requirements, low recovery rate, limited application and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

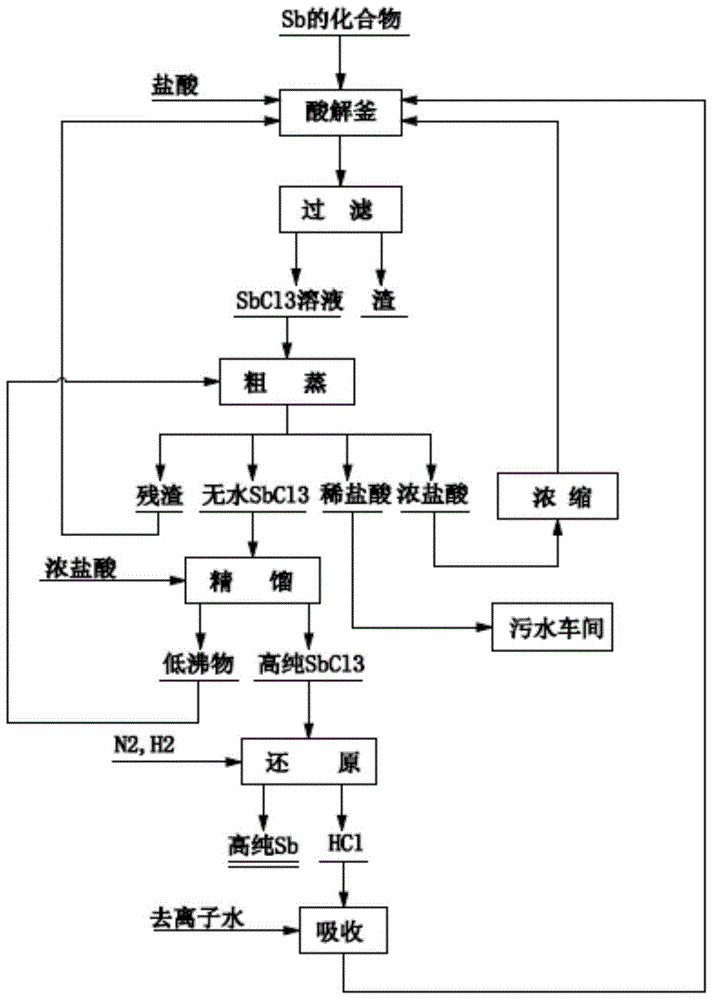

[0031] The invention provides a preparation method of antimony, comprising:

[0032] 1) SbCl 3 Mix with hydrochloric acid, carry out rectification, obtain antimony trichloride after rectification,

[0033] The mass concentration of the hydrochloric acid is 30%~38%,

[0034] The SbCl 3 The volume ratio with the hydrochloric acid is (100-800): 1;

[0035] 2) Reducing antimony trichloride after rectification to obtain antimony.

[0036] According to the present invention, the present invention will SbCl 3 mixed with hydrochloric acid, and rectified to obtain antimony trichloride after rectification; wherein, the SbCl 3 The volume ratio to the hydrochloric acid is preferably (150-600): 1, more preferably (200-500): 1; most preferably (250-450): 1; the rectification is preferably two-stage rectification; Wherein, in the first section of rectification, the rectification kettle temperature is preferably 150-190°C, more preferably 160-180°C, most preferably 170-175°C; the top te...

Embodiment 1

[0046] Take 1kg of industrial product 99.8% antimony oxide and 2.8L of 31% industrial hydrochloric acid for acid hydrolysis reaction, the reaction temperature is 30°C, the stirring speed is 350r / min, the reaction time is 3h, and the obtained SbCl 3 The solution contains 260g / L of antimony, and the leaching rate of antimony oxide is 97.5%. After the acidolysis reaction was completed and the insoluble matter was removed by filtration, the clarified SbCl 3 The solution is sent to distillation.

[0047] Distillation is carried out in three stages: the temperature of the first stage is 115°C, and the distillate contains Sb 3+ 0.039g / L, free acid concentration 0.243mol / L, due to the low content of antimony and acid concentration, it can be directly sent to the sewage workshop for treatment; the temperature of the second stage is 185°C, and the distillate contains Sb 3+ 30g / L, free acid concentration 3.01mol / L, this part of the distillate has recovery value, but its acidity is not ...

Embodiment 2

[0062] Take 1kg Sb 4 o 5 Cl 2 Carry out acid hydrolysis reaction with 2.4L 35% industrial hydrochloric acid, the reaction temperature is 40°C, the stirring speed is 400r / min, the reaction time is 2h, the obtained SbCl 3 The solution contains 270g / L of antimony, and the leaching rate of antimony is 98.0%. After the acidolysis reaction was completed and the insoluble matter was removed by filtration, the clarified SbCl 3 The solution is sent to distillation.

[0063] Distillation is carried out in three stages: the temperature of the first stage is 115°C, and the distillate contains Sb 3+ 0.045g / L, free acid concentration 0.327mol / L, due to the low content of antimony and acid concentration, it can be directly sent to the sewage workshop for treatment; the temperature of the second stage is 190°C, and the distillate contains Sb 3+ 40g / L, free acid concentration 2.8mol / L, this part of the distillate has recovery value, but its acidity is not up to the acidity required for ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com