N-doped porous carbon/NiO composite material and preparation method therefor

A composite material and porous carbon technology, which can be used in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., and can solve the problems of narrow potential window, high price, and dense structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

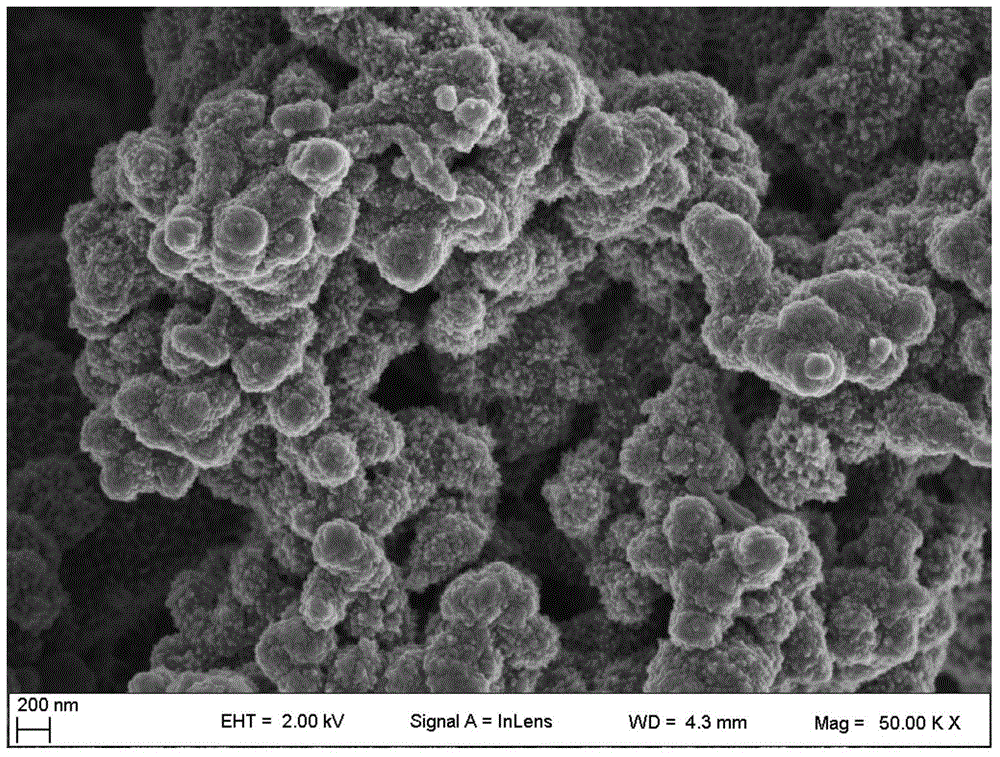

[0039] The preparation method of the N-doped porous carbon / NiO composite material of this embodiment includes:

[0040] Step 1, preparing coal-based polyaniline by in-situ polymerization, specifically comprising the following steps:

[0041] Step 101. Mix 10 g of aniline, 30 mL of concentrated hydrochloric acid (37% in mass concentration) and 60 mL of water to obtain a mixed solution B, add 10 g of coal powder to the mixed solution B, stir and swell at 30°C for 3 hours to obtain swollen coal Sample;

[0042] Step 102. Add 80 mL of ammonium persulfate aqueous solution with a concentration of 0.30 g / mL dropwise to the swollen coal sample described in step 101 in a 3° C. ice-water bath with stirring at a rate of 2 mL / min. After the dropwise addition is completed, Continue to stir for 6 hours under the condition of ice-water bath at 3°C, filter with suction, wash the filter cake obtained by suction filtration, then vacuum-dry the filter cake after washing, grind it, and pass it t...

Embodiment 2

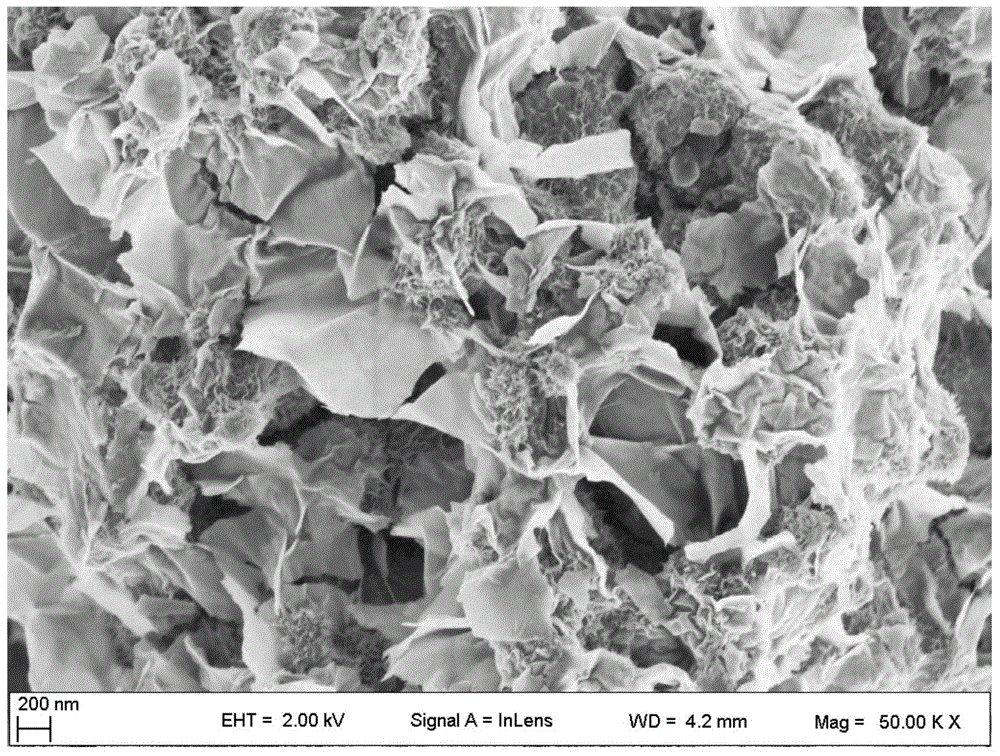

[0048] The preparation method of the N-doped porous carbon / NiO composite material of this embodiment includes:

[0049] Step 1, preparing coal-based polyaniline by in-situ polymerization, specifically comprising the following steps:

[0050] Step 101: Mix 20g of aniline, 30mL of concentrated hydrochloric acid (37% in mass concentration) and 50mL of water to obtain a mixed solution B, add 10g of coal powder to the mixed solution B, stir and swell at 35°C for 2h to obtain swollen coal Sample;

[0051] Step 102. Add 100 mL of ammonium persulfate aqueous solution with a concentration of 0.48 g / mL dropwise to the swollen coal sample described in step 101 under agitation in an ice-water bath at 0° C. at a rate of 3 mL / min. After the dropwise addition is completed, Continue to stir for 8 hours under the condition of an ice-water bath at 0°C, filter with suction, wash the filter cake obtained by suction filtration, then dry the washed filter cake in vacuum, grind it, and pass it thro...

Embodiment 3

[0057] The preparation method of the N-doped porous carbon / NiO composite material of this embodiment includes:

[0058] Step 1, preparing coal-based polyaniline by in-situ polymerization, specifically comprising the following steps:

[0059] Step 101. Mix 10g of aniline, 25mL of concentrated hydrochloric acid (37% in mass concentration) and 55mL of water to obtain a mixed solution B, add 8g of coal powder to the mixed solution B, stir and swell at 25°C for 2.5h to obtain a swollen coal sample;

[0060] Step 102. Add 60 mL of ammonium persulfate aqueous solution with a concentration of 0.40 g / mL dropwise to the swollen coal sample described in step 101 in an ice-water bath at 5° C. with stirring at a rate of 1 mL / min. After the dropwise addition is completed, Continue to stir for 7 hours under the condition of ice-water bath at 5°C, filter with suction, wash the filter cake obtained by suction filtration, then vacuum-dry the filter cake after washing, grind it, and pass it thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com