A kind of slow and controlled release pesticide granule and preparation method thereof

A technology of controlled-release pesticides and granules, applied in the field of pesticides, can solve the problems of single structure of slow-controlled pesticide granules, and achieve the effects of reducing the number of spraying times, being environmentally friendly, and good slow-release effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

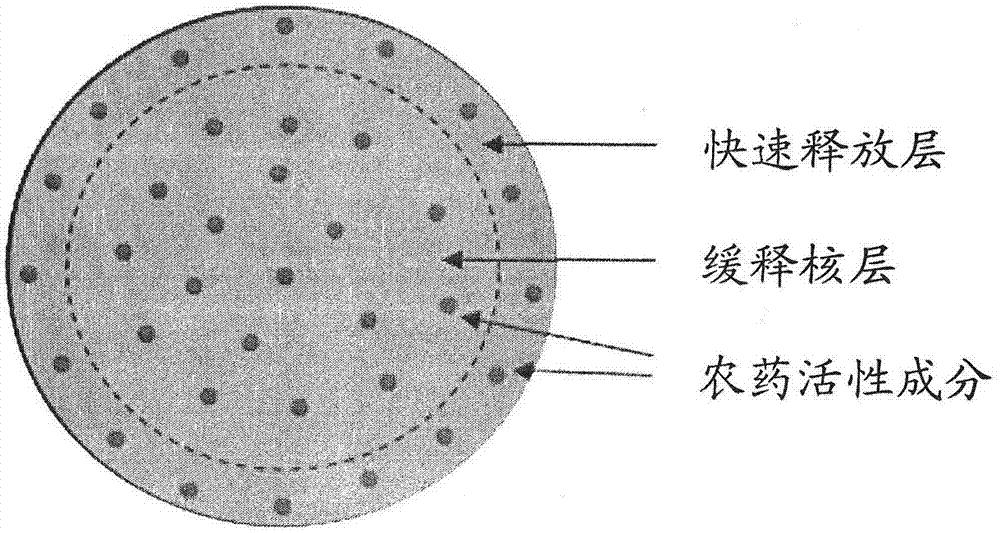

[0070] The present invention provides the preparation method of the sustained and controlled release pesticide granule described in the above technical scheme, comprising the following steps:

[0071] (1) Mixing pesticide active ingredients, modified phosphogypsum, organic feces, biomass materials, auxiliary agents and fillers to obtain a mixed material;

[0072] (2) granulate the mixed material obtained in the step (1) after being humidified to 20% to 30%, to obtain the slow-release core layer and the remaining powder;

[0073] (3) Throwing the slow-release core layer obtained in the step (2) and the remaining powder into a circle, and the remaining powder is coated on the surface of the slow-release core layer to form a slow-controlled release pesticide granule.

[0074] The invention mixes the pesticide active ingredients, modified phosphogypsum, organic feces, biomass materials, auxiliary agents and fillers to obtain a mixed material. In the present invention, there are n...

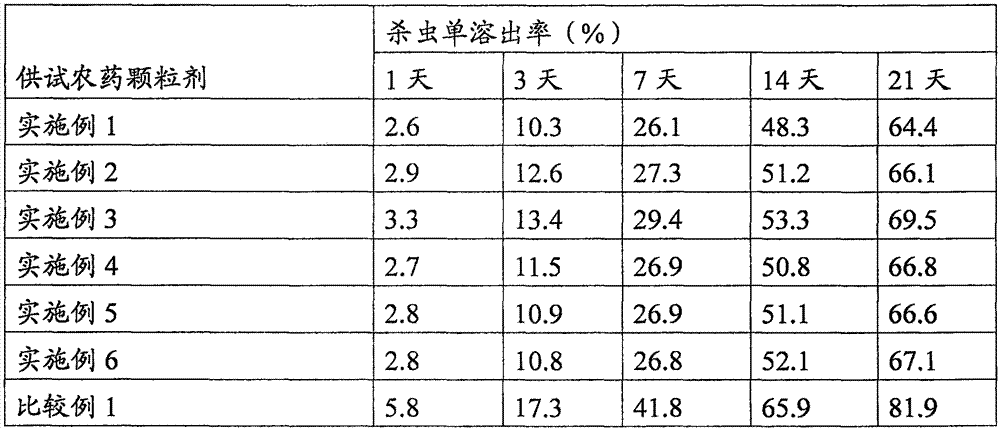

Embodiment 1

[0085] Preparation of 5% monosultap·chlorpyrifos slow-release pesticide granules

[0086] Preparation of modified phosphogypsum: mixing phosphogypsum with lime water for neutralization reaction to obtain modified phosphogypsum with a pH value of 5. Then put it into an oven, the temperature of the oven is 170° C., bake for 3 hours, and measure the water content of the modified phosphogypsum to be below 10%. The dried modified phosphogypsum is pulverized, and then passed through a 40-mesh sieve to obtain the under-sieve part.

[0087] Preparation of 5% monosultap · chlorpyrifos slow-release pesticide granules: by weight percentage, get 2.5% monosultap original drug, 2.5% chlorpyrifos original drug, 70% modified phosphogypsum, 9% organic chicken Feces, 3% bagasse, 0.5% sodium lauryl sulfate, and kaolin to make up the balance to 100%, mix well and humidify to 25%. The obtained mixture is granulated by a horizontal centrifugal extrusion granulator, rounded by a rounder, then drie...

Embodiment 2

[0089] Preparation of 5% monosultap·chlorpyrifos slow-release pesticide granules

[0090] Preparation of modified phosphogypsum: mixing phosphogypsum with lime water for neutralization reaction to obtain modified phosphogypsum with a pH value of 6. Then put it into an oven, the temperature of the oven is 160° C., bake for 2 hours, and measure the water content of the modified phosphogypsum to be below 10%. The dried modified phosphogypsum is pulverized, and then passed through a 40-mesh sieve to obtain the under-sieve part.

[0091] Preparation of 5% monosultap · chlorpyrifos slow and controlled release pesticide granules: by weight percentage, get 2.5% monosultap original drug, 2.5% chlorpyrifos original drug, 50% modified phosphogypsum, 9% organic chicken Feces, 3% bagasse, 0.5% sodium lauryl sulfate, and kaolin to make up the balance to 100%, mix well and humidify to 25%. The obtained mixture is granulated by a horizontal centrifugal extrusion granulator, rounded by a rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com