Method for degrading lignin using visible-light response composite catalyst

A composite catalyst and visible light technology, which is applied in the field of effective utilization of lignin resources, can solve the problems of benzene ring damage and non-compliance, and achieve the effect of high benzene ring retention rate and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

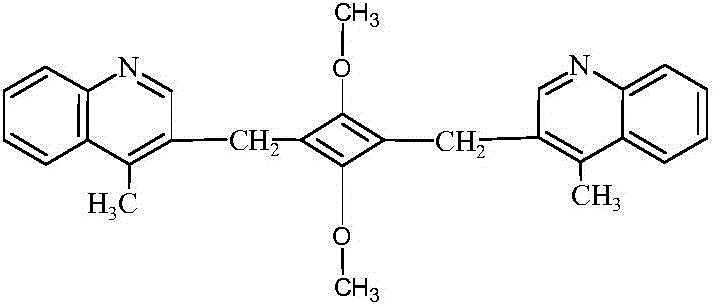

[0023] Mix 1g of refined lignin, 100mL of distilled water, 20mL of n-butanol, 0.020g of dimethyl ether quinoline squaraine (see attached figure 1 ), 0.0500g nano-TiO 2 (The particle size of the photocatalyst is 2nm~50nm) Avoid light and ultrasonically disperse for 20min, then irradiate with sunlight for 6h; after the reaction, let stand for 2h, then centrifuge at 8000rad / min at high speed, wash 3 times with distilled water, and the solid residue is degraded Lignin Ⅰ was then dissolved in alkali and acid-precipitated to obtain flocculent precipitates, and dried in vacuum at 80°C with a yield of 63.12%; DPPH free radical (1,1-diphenyl-2-trinitrobenzene Hydrazine, see attached Figure 4 ) Determination of antioxidant capacity: IC of lignin 50 (required concentration to remove 50% of DPPH free radicals) value is 0.199mg / mL; degraded lignin Ⅰ has higher antioxidant ability to DPPH free radicals than original lignin, and its IC 50 The value is 0.127mg / mL; compared with the common...

example 2

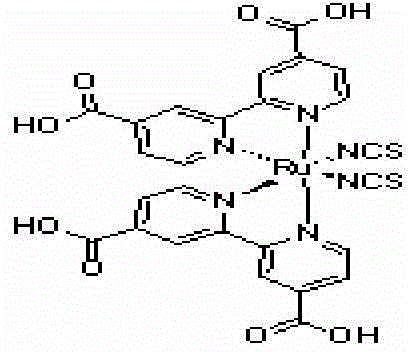

[0028] 1g refined lignin, 100mL distilled water, 20mL n-butanol, 0.02g ruthenium complex N3 dye [chemical name: CIS-dithiocyanatobis(N,N'-2,2'-bipyridine-4,4 '-diformic acid) ruthenium] (see attached figure 2 ), 0.0500g nano-TiO 2 (The particle size of the photocatalyst is 2nm~50nm) Avoid light and ultrasonically disperse for 20min, and then irradiate with sunlight for 6h; centrifuge after the reaction, discard the supernatant, and wash the remaining solid twice with an appropriate amount of distilled water; then dissolve in alkali, acid A flocculent precipitate was obtained, and after centrifugation, washing, and drying, the degraded lignin II was obtained with a yield of 45.82%; the degraded lignin II was subjected to DPPH free radical (1,1-diphenyl-2-trinitrophenylhydrazine, See attached Figure 4 ) Determination of antioxidant capacity: IC of lignin 50 (required concentration to remove 50% of DPPH free radicals) value is 0.199mg / mL; degraded lignin II has higher antioxid...

example 3

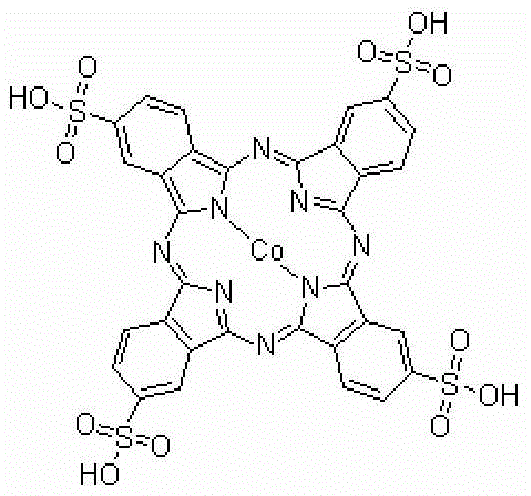

[0032] Mix 1g refined lignin, 100mL distilled water, 20mL n-butanol, 0.02g tetracarboxylic cobalt phthalocyanine (see attached image 3 ), 0.0500g nano-TiO 2 (The particle size of the photocatalyst is 2nm~50nm) Avoid light and ultrasonically disperse for 20min, and then irradiate with sunlight for 6h; centrifuge after the reaction, discard the supernatant, and wash the remaining solid twice with an appropriate amount of distilled water; then dissolve in alkali, acid A flocculent precipitate was obtained, and after centrifugation, washing, and drying, the lignin activation product III was obtained with a yield of 48.82%; the degraded lignin III was subjected to DPPH free radical (1,1-diphenyl-2-trinitrophenylhydrazine , see attached Figure 4 ) Determination of antioxidant capacity: IC of lignin 50 (required concentration to remove 50% of DPPH free radicals) value is 0.199mg / mL; degraded lignin Ⅲ has higher antioxidant ability to DPPH free radicals than original lignin, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com