A sand grain epoxy powder coating

An epoxy powder and coating technology, applied in the field of powder coatings, can solve the problems of chemical resistance, high temperature resistance, poor impact resistance, poor medium penetration resistance, poor long-term anti-corrosion effect, etc., and achieves high cross-linking density. , The effect of reducing daily maintenance and cleaning, excellent internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Weigh the components according to the following mass ratios,

[0062] 60 parts of modified epoxy resin

[0063] 1 part acrylic polymer

[0064] 60 parts of polyester resin

[0065] Coupling agent modified pigment 3 parts

[0066] 60 parts of coupling agent modified filler

[0067] Nano calcium carbonate 3 parts

[0068] Sand texture agent 0.2 parts

[0069] Hardening agent 1 part

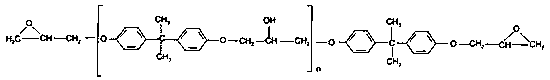

[0070] Modified epoxy resin is one or more in chemical formula A, chemical formula B;

[0071] The chemical formula A is

[0072] ,

[0073] The chemical formula B is

[0074] ;

[0075] The preparation method of the coupling agent modified pigment is as follows:

[0076] Measure 35 parts of silane coupling agent and 65 parts of pigment respectively according to the mass ratio, add the silane coupling agent into the pigment evenly and mix the materials at the same time to make the mixture uniform.

[0077] The preparation method of coupling agent modified filler is as follo...

Embodiment 2

[0083] 1. Weigh the components according to the following mass ratios,

[0084] Modified epoxy resin 90 parts

[0085] Acrylic polymer 2 parts

[0086] 90 parts of polyester resin

[0087] Coupling agent modified pigment 10 parts

[0088] Coupling agent modified filler 90 parts

[0089] Nano calcium carbonate 5 parts

[0090] Sand texture agent 0.4 parts

[0091] Hardening agent 1.5 parts

[0092] 3.5 parts of loosening agent,

[0093] Modified epoxy resin is one or more in chemical formula A, chemical formula B;

[0094] The chemical formula A is

[0095] ,

[0096] The chemical formula B is

[0097] ;

[0098] The preparation method of the coupling agent modified pigment is as follows:

[0099] Measure 30 parts of silane coupling agent and 60 parts of pigment respectively according to the mass ratio, add the silane coupling agent evenly into the pigment and mix the materials at the same time, so that the mixture is uniform.

[0100] The preparation method of...

Embodiment 3

[0106] 1. Weigh the components according to the following mass ratios,

[0107] Modified epoxy resin 70 parts

[0108] Acrylic polymer 1.3 parts

[0109] 70 parts of polyester resin

[0110] Coupling agent modified pigment 6 parts

[0111] Coupling agent modified filler 70 parts

[0112] Nano calcium carbonate 4 parts

[0113] Sand texture agent 0.3 parts

[0114] Hardening agent 2 parts

[0115] 1 part loosening agent,

[0116] Modified epoxy resin is one or more in chemical formula A, chemical formula B;

[0117] The chemical formula A is

[0118] ,

[0119] The chemical formula B is

[0120] ;

[0121] The preparation method of the coupling agent modified pigment is as follows:

[0122] Measure 40 parts of silane coupling agent and 70 parts of pigment respectively according to the mass ratio, add silane coupling agent evenly into the pigment and mix the materials at the same time to make the mixture uniform.

[0123] The preparation method of coupling agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com