Carbon/carbon composite material binder, bonding method and carbon/carbon composite material member

A technology of carbon composite materials and binders, applied in the direction of aldehyde/ketone condensation polymer binders, adhesives, adhesive types, etc., can solve the problem that the binder is not suitable for high temperature and corrosive environments, and the binder is difficult to fully meet the application requirements and other problems, to achieve the effect of good resistance to strong acid, convenient preparation, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 10 grams of phenolic resin (solid content 60%, viscosity 0.5 Pa s), 1 gram of chopped carbon fiber powder (length 100 ± 50 μm) and mix well to obtain a corrosion-resistant high-strength adhesive;

[0034] (2) Using carbon / carbon composite material as the bonding material, adopt absolute ethanol and acetone to clean and dry the bonding material;

[0035] (3) After brushing uniform adhesive on the joint surface of the bonding material, let it stand for 2 hours and then bond, and the bonding pressure is 1MPa;

[0036] (4) The bonded carbon / carbon composite material sample cured at room temperature was raised to 180°C for 2 hours at a heating rate of 1°C / min;

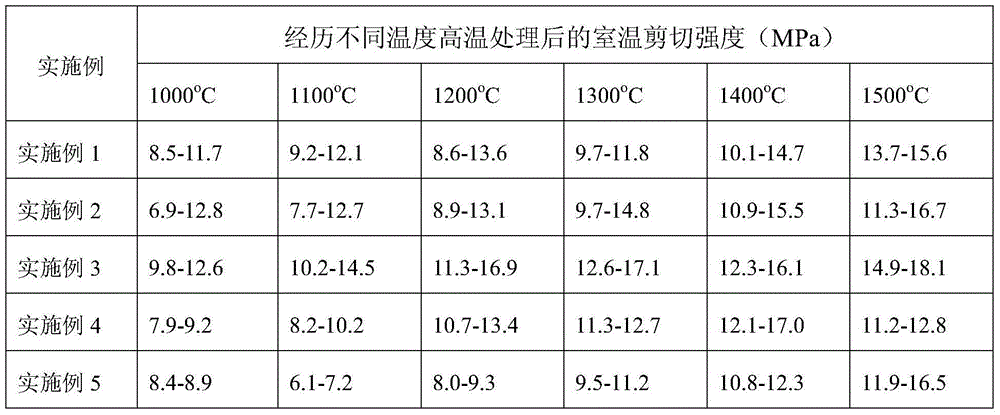

[0037] (5) Place the cured bonded carbon / carbon composite material in a heat treatment furnace, and raise the temperature to 1000°C, 1100°C, 1200°C, 1300°C, 1400°C, Heat treatment at 1500°C for 2 hours at high temperature. After taking it out, test the bond shear strength at different heat treatment temperat...

Embodiment 2

[0039] (1) Weigh 10 grams of phenolic resin (solid content 65%, viscosity 1.0 Pa s), 2 grams of chopped carbon fiber powder (length 200 ± 50 μm) and mix well to obtain a corrosion-resistant high-strength adhesive;

[0040] (2) Using carbon / carbon composite material as the bonding material, use absolute ethanol and acetone to clean and dry the bonding material

[0041] (3) After brushing uniform adhesive on the joint surface of the adhesive material, let it stand for 4 hours before bonding, and the bonding pressure is 2MPa;

[0042] (4) The bonded carbon / carbon composite material sample cured at room temperature was raised to 180°C for 2 hours at a heating rate of 3°C / min;

[0043] (5) Put the cured bonded carbon / carbon composite material in a heat treatment furnace, and raise the temperature to 1000°C, 1100°C, 1200°C, 1300°C, 1400°C, Heat treatment at 1500°C for 2 hours at high temperature. After taking it out, test the bond shear strength at different heat treatment temperat...

Embodiment 3

[0045] (1) Weigh 10 grams of phenolic resin (solid content 70%, viscosity 1.5 Pa s), 3 grams of chopped carbon fiber powder (length 300 ± 50 μm) and mix well to obtain a corrosion-resistant high-strength adhesive;

[0046] (2) Using carbon / carbon composite material as the bonding material, use absolute ethanol and acetone to clean and dry the bonding material

[0047] (3) After applying a uniform adhesive on the joint surface of the adhesive material, let it stand for 6 hours before bonding, and the bonding pressure is 3MPa;

[0048] (4) The bonded carbon / carbon composite material sample cured at room temperature was raised to 180°C for 2 hours at a heating rate of 5°C / min;

[0049] (5) Put the cured bonded carbon / carbon composite material in a heat treatment furnace, and raise the temperature to 1000°C, 1100°C, 1200°C, 1300°C, 1400°C, Heat treatment at 1500°C for 2 hours at high temperature. After taking it out, test the bond shear strength at different heat treatment temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com