Method for preparing carbon quantum dots by virtue of polyethyleneimine decomposition

A polyethyleneimine, carbon quantum dot technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of cumbersome preparation steps, increased cytotoxicity, poor product stability, etc., and achieves wide application range, simple preparation process, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

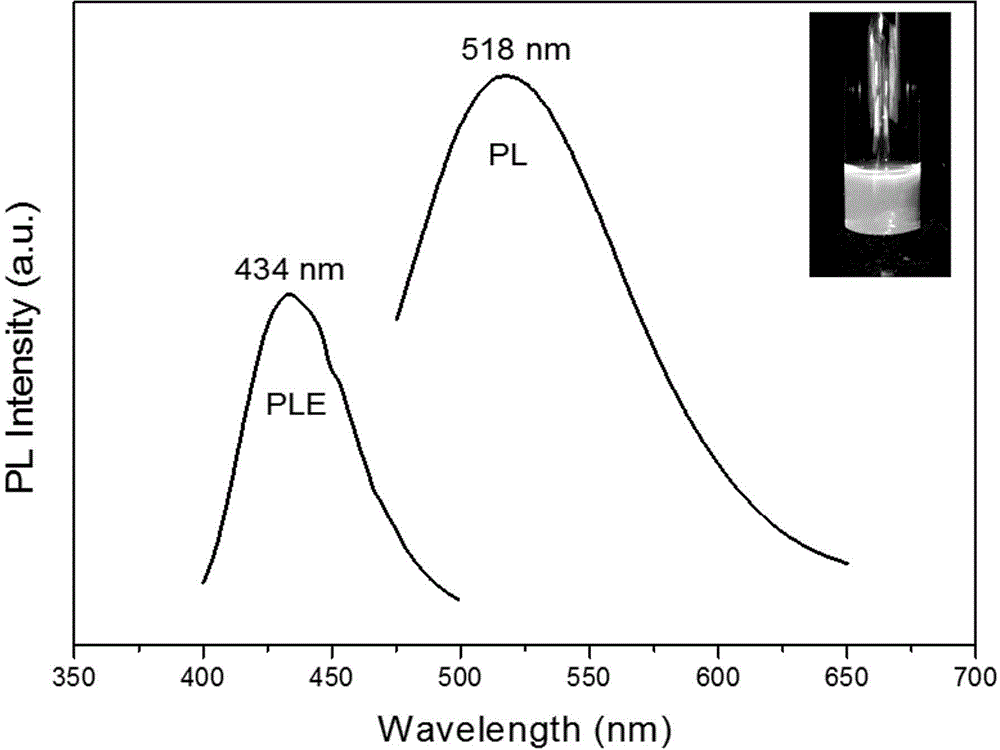

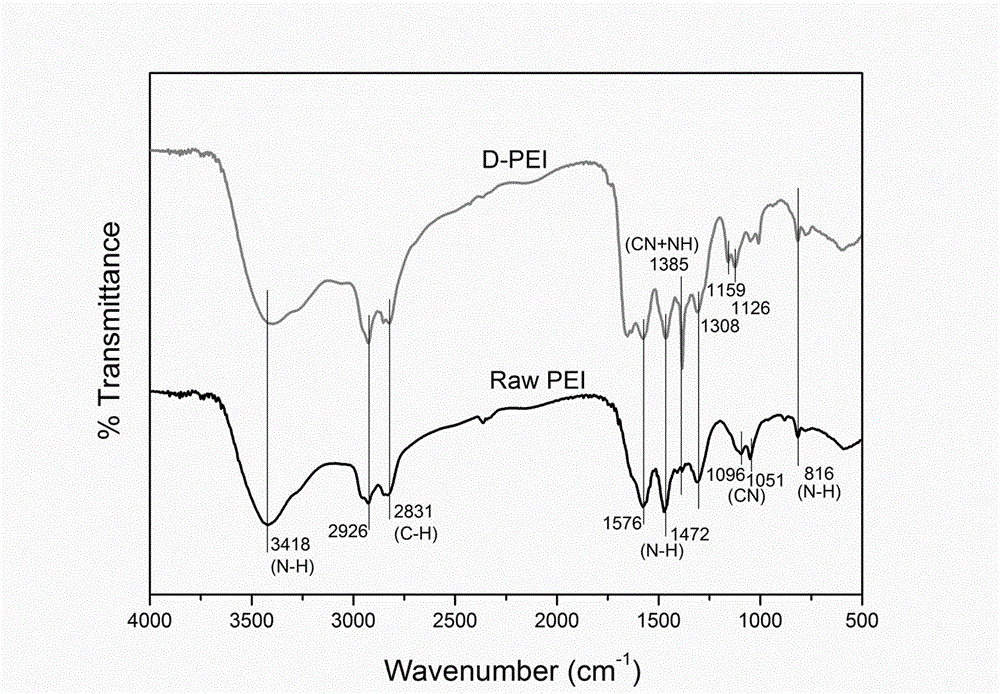

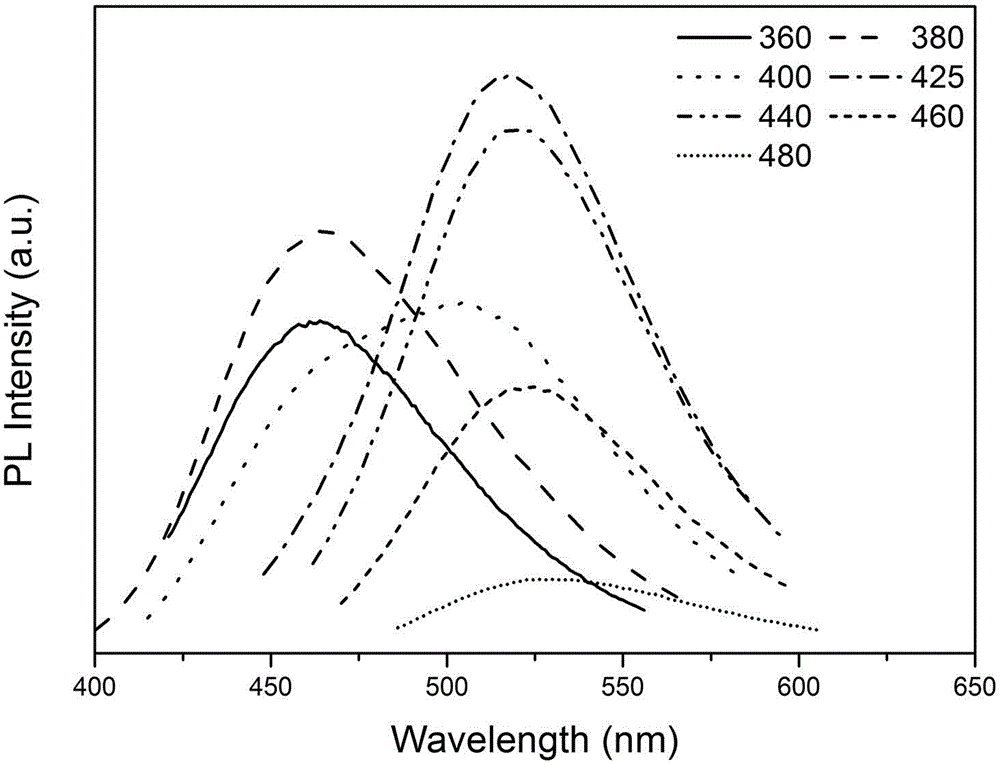

[0022] Disperse 200mg of polyethyleneimine in 40ml of ethanol, stir well, transfer the solution to a reaction kettle, raise the temperature to 200°C for 20h, and cool to room temperature. Using column chromatography, the product is separated and purified to obtain nitrogenized carbon quantum dots that emit yellow-green light under the excitation of 365nm ultraviolet light, such as figure 1 Shown (where, PLE is the photoluminescence excitation spectrum; PL is the photoluminescence spectrum). The Fourier transform infrared spectra of polyethyleneimine before reaction and carbon quantum dots after reaction are as follows: figure 2 shown. The prepared nitriding carbon quantum dot ethanol solution showed strong yellow-green fluorescence under ultraviolet light, and the photoluminescence spectra under different excitation wavelengths were as follows: image 3 shown. Its maximum excitation wavelength is 430nm, and the maximum fluorescence emission wavelength at this time is 514nm...

Embodiment 2

[0024] Disperse 50mg of polyethyleneimine in 40ml of ethanol, stir well, transfer the solution to a reaction kettle, raise the temperature to 200°C for 20h, and cool to room temperature. The product is separated and purified by column chromatography to obtain nitrogenized carbon quantum dots that emit yellow-green light under the excitation of 365nm ultraviolet light.

Embodiment 3

[0026] Disperse 100mg of polyethyleneimine in 40ml of ethanol, stir well, transfer the solution to a reaction kettle, raise the temperature to 180°C for 20h, and cool to room temperature. The product is separated and purified by column chromatography to obtain nitrogenized carbon quantum dots that emit yellow-green light under the excitation of 365nm ultraviolet light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com