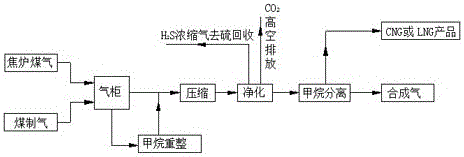

Method for preparing synthesis gas from coke oven gas and coal-to-gas

A coke oven gas and coal-to-gas technology, which is applied in chemical instruments and methods, gas fuels, petroleum industry, etc., can solve the problems of complex operation, unbalanced component ratio, insufficient utilization, etc. The effect of controllable carbon ratio and easy operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The coke oven gas produced by the top-loading coke oven (volume percentage composition is H 2 : 54%, CH 4: 25%, CO+CO 2 :15%,N 2 : 6%) and the coal-to-gas produced by pressurized gasification of crushed coal (volume percentage composition is CO: 52%, H 2 : 23%, CO 2 : 14%, CH 4 : 11%, H 2 S: 0.25%) according to the molar flow ratio of 6.0: 1 into the gas cabinet for full mixing, 40% of the volume of the mixed gas is carried out in Ni / γ-Al 2 o 3 Catalyst, methane reforming under the conditions of temperature 610°C and pressure 1.2 MPa, the reformed gas is combined with the remaining 60% volume of mixed gas for compression to form a crude raw material gas with a hydrogen-carbon molar ratio of 3.13, and the crude raw material gas is compressed Enter the low-temperature methanol washing and purification, and remove H at a pressure of 4.5MPa and a temperature of -43°C 2 S and CO 2 and other impurities to obtain H 2 S content is less than 0.1ppm, CO 2 Feed gas with...

Embodiment 2

[0037] The coke oven gas (volume percentage composition as H 2 : 60%, CH 4 : 23%, CO+CO 2 :11%,N 2 : 6%) and coal-to-gas produced by pressurized gasification of crushed coal (volume percentage composition is CO: 54%, H 2 : 26%, CO 2 : 10%, CH 4 : 10%, H 2 S: 0.03%) according to the molar flow ratio of 2.0: 1 into the gas cabinet for full mixing, about 25% of the volume of the mixed gas enters methane reforming, in Ru / γ-Al 2 o 3 Catalyst, reforming at a temperature of 710°C and a pressure of 2.0 MPa, combining the reformed gas and the mixed gas for compression to form a crude raw material gas with a hydrogen-to-carbon molar ratio of 2.08, and the crude raw material gas is purified by thermal alkali method after compression. Remove H at a pressure of 1.6MPa and a temperature of 98°C 2 S and CO 2 and other impurities to obtain H 2 S content is less than 0.1ppm, CO 2 Feed gas with a content of less than 20ppm, the removed H 2 S desulfurization recovery, CO removal 2 T...

Embodiment 3

[0039] The coke oven gas (volume percentage composition as H 2 : 48%, CH 4 : 28%, CO+CO 2 :17%,N 2 : 7%) and Texaco coal-water slurry gasifier to produce coal-to-gas (volume percentage composition is CO: 49%, H 2 : 24%, CO 2 : 14%, CH 4 : 13%, H 2 S: 0.03%) according to the molar flow ratio of 6.0: 1 into the gas cabinet for full mixing, about 80% of the volume of the mixed gas enters the methane reforming, in the Ru / γ-Al 2 o 3 Catalyst, reforming at a temperature of 670°C and a pressure of 2.3 MPa, combining the reformed gas and the mixed gas for compression to form a crude raw material gas with a hydrogen-to-carbon molar ratio of 2.27, and the crude raw material gas enters low-temperature methanol washing and purification after compression , at a pressure of 5.0MPa and a temperature of -49°C to remove H 2 S and CO 2 and other impurities to obtain H 2 S content is less than 0.1ppm, CO 2 Feed gas with a content of less than 20ppm, the removed H 2 S desulfurization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com