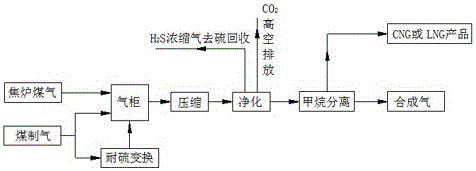

A method for producing synthesis gas from coke oven gas and coal gas

A technology of coke oven gas and coal gas, which is applied in the production of hydrogen, gas fuel, petroleum industry, etc., to achieve the effect of single process and easy operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The coke oven gas produced by the top-loading coke oven (volume percentage composition is H 2 : 55%, CH 4 : 25%, CO+CO 2 :15%,N 2 : 5%) and 80% volume of coal-to-gas produced by pressurized gasification of crushed coal (volume percentage composition is CO: 49%, H 2 : 24%, CO 2 : 14%, CH 4 : 13%, H 2 S: 0.25%) into the gas holder, the molar flow ratio of coke oven gas and coal-based gas is 1.35:1, and another part of 20% of the volume of coal-based gas enters the sulfur-resistant water-vapour conversion equipped with Qingdao Lianxin QDB series catalyst, Airspeed is 2600h -1 , pressure 3.0MPa, temperature 360°C for sulfur-resistant transformation, the transformation gas and the mixed gas are combined and compressed to form a crude raw material gas with a hydrogen-carbon molar ratio of 2.28, and the crude raw material gas is washed and purified with low-temperature methanol after compression. Remove H at a pressure of 4.0MPa and a temperature of -45°C 2 S and CO 2...

Embodiment 2

[0039] The coke oven gas (volume percentage composition as H 2 : 62%, CH 4 : 23%, CO+CO 2 :10%,N 2 : 5%) and about 90% of the volume of coal-to-gas produced by pressurized gasification of crushed coal (volume percentage composition is CO: 59%, H 2 : 20%, CO 2 : 12%, CH 4 : 9%, H 2 S: 0.35%) into the gas holder, the molar flow ratio of coke oven gas and coal-to-gas is 2.0:1, and another part of about 10% of the volume of coal-to-gas enters the QCS-01 catalyst produced by Qilu Petrochemical Research Institute. Sulfur-water-vapor shift at a space velocity of 3300h -1 , pressure 3.5MPa, temperature 380°C for sulfur-resistant transformation, the transformation gas and the mixed gas are combined and compressed to form a crude raw material gas with a hydrogen-carbon molar ratio of 2.36, and the crude raw material gas is purified by thermal alkali method after compression. Removal of H at a pressure of 1.4MPa and a temperature of 100°C 2 S and CO 2 and other impurities to obt...

Embodiment 3

[0041] The coke oven gas produced by the top-loading coke oven (volume percentage composition is H 2 : 60%, CH 4 : 24%, CO+CO 2 :12%,N 2 : 4%) and about 70% volume of coal-to-gas produced by Lurgi furnace gasification (volume percentage composition is CO: 50%, H 2 : 25%, CO 2 : 10%, CH 4 : 15%, H 2 S: 0.28%) into the gas holder, the molar flow ratio of coke oven gas and coal-based gas is 1.5:1, and another part of about 30% of the volume of coal-based gas enters the K8-11 type catalyst produced by the British ICI company. Sulfur-water vapor shift, at a space velocity of 5800h -1 , pressure 4.0MPa, temperature 370°C for sulfur-resistant transformation, the transformation gas and the mixed gas are combined and compressed to form a crude raw material gas with a hydrogen-carbon molar ratio of 3.11, and the crude raw material gas is purified by NHD after compression. 2.8MPa, H removal at 1°C 2 S and CO 2 and other impurities to obtain H 2 S content is less than 0.1ppm, CO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com