Fish feed additive preparation method

An additive and fish feed technology, applied in the field of preparation of fish feed additives, can solve problems such as mycotoxin pollution, achieve the effects of increasing adsorption area, balancing nutrition, and improving feed utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

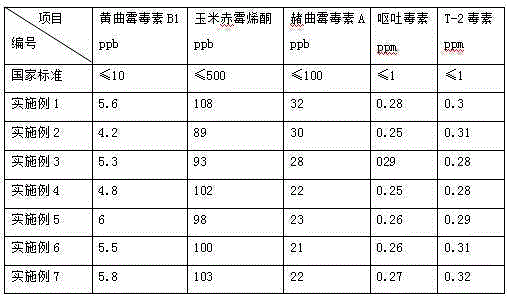

Examples

Embodiment 1

[0021] A preparation method of a fish feed additive, said method comprising the steps of:

[0022] A. After pulverizing demosmectite and humic acid, mix them in a ratio of 3.5:1, add 5% yeast fermentation broth and 10% Bacillus fermentation broth, stir evenly, adjust the pH value to 8.5, shake for 10 hours, and then After natural air-drying at room temperature for 3 days, the composite was pulverized and set aside;

[0023] B. Weigh 2 parts of pine needle powder, 0.3 part of cellulase, 1 part of methionine, 0.5 part of premix and 1 part of the complex prepared in step A, mix them, and stir evenly to obtain the fish feed additive. In order to implement the present invention better, the usage amount of the additive of the present embodiment is 2.3%.

Embodiment 2

[0025] A preparation method of a fish feed additive, said method comprising the steps of:

[0026] A. After pulverizing demosmectite and humic acid, mix them in a ratio of 4.2:1, add 6% yeast fermentation broth and 12% Bacillus fermentation broth, stir evenly, adjust the pH value to 8.7, shake for 12 hours, and then After natural air-drying at room temperature for 4 days, the composite was pulverized and set aside;

[0027] B. Weigh 4 parts of pine needle powder, 0.5 part of cellulase, 1.2 part of methionine, 0.8 part of premix and 2 parts of the complex prepared in step A, mix them, and stir evenly to obtain the fish feed additive. In order to implement the present invention better, the practical amount of the additive of the present embodiment is 2.5%.

Embodiment 3

[0029] A preparation method of a fish feed additive, said method comprising the steps of:

[0030] A. After pulverizing demosmectite and humic acid, mix them in a ratio of 5:1, add 8% yeast fermentation broth and 15% Bacillus fermentation broth, stir evenly, adjust the pH value to 9, shake for 15 hours, and then After natural air-drying at room temperature for 5 days, the composite was pulverized and set aside;

[0031] B. Weigh 5 parts of pine needle powder, 0.6 part of cellulase, 1.5 parts of methionine, 1 part of premix and 3 parts of the complex prepared in step A, mix them, and stir evenly to obtain the fish feed additive. In order to implement the present invention better, the practical amount of the additive of the present embodiment is 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com