Alkyne, sulfur and amine multi-component polymerization method for preparing poly-thioamide

A polythioamide, polymerization method technology, applied in the field of multi-component polymerization of alkynes, sulfur and amines, to achieve the effects of high polymer yield, high molecular weight and high atom economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of multi-component polymerization method of alkynes, sulfur and amines for preparing polythioamides in this embodiment, the specific preparation steps are as follows:

[0032] (1) Under the protection of an inert gas, add 68mg of p-xylylenediamine, 94.5mg of 1,4-diethynylbenzene and 64mg of sublimed sulfur into 0.5mL of pyridine to dissolve, raise the temperature to 50-60°C, and react under stirring for 24h ;

[0033] (2) After the reaction is completed, cool to room temperature, dilute the reaction mother liquor with 1mL dimethylformamide solution, add it dropwise to 20mL methanol for precipitation, collect the precipitate, and dry to constant weight to obtain polythioamide.

[0034] The polythioamide of the present embodiment has the structural formula shown in P1:

[0035]

[0036] The reaction equation involved in this embodiment is as follows:

[0037]

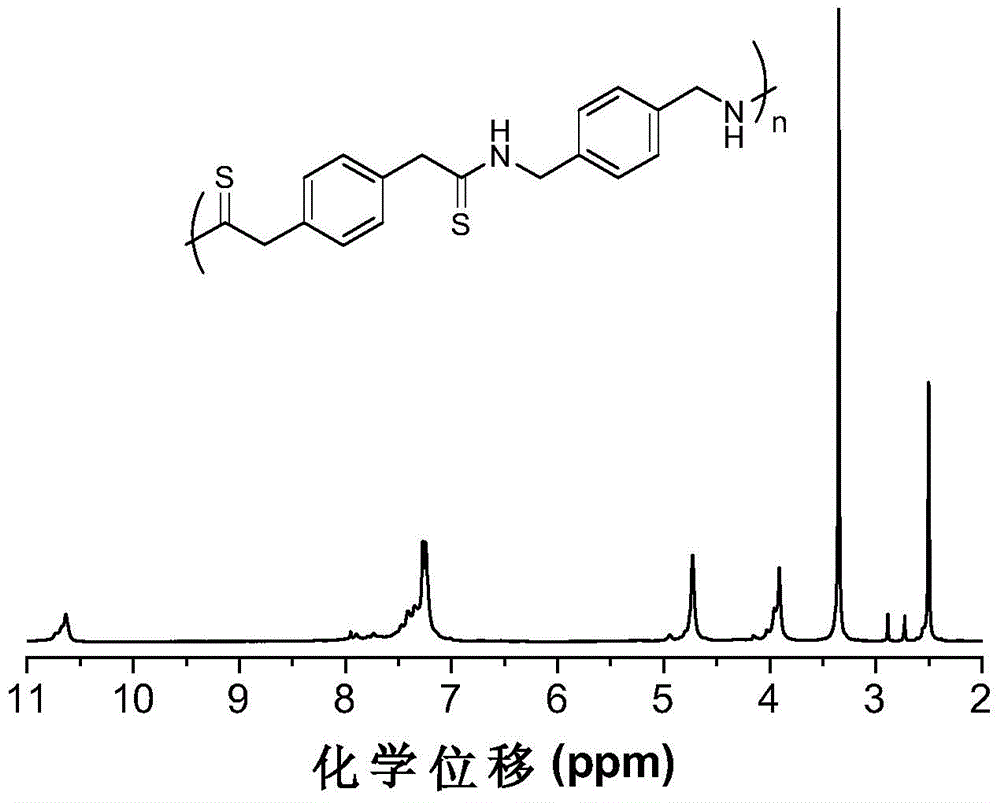

[0038] The proton nuclear magnetic spectrum of the polythioamide of the present embodiment in deu...

Embodiment 2

[0043] A kind of multi-component polymerization method of alkynes, sulfur and amines for preparing polythioamides in this embodiment, the specific preparation steps are as follows:

[0044] (1) Under the protection of an inert gas, 68 mg of p-xylylenediamine, 285 mg of diethynyltetraphenylethylene and 64 mg of sublimed sulfur were dissolved in 0.5 mL of pyridine, heated to 100-120 °C, and reacted for 4 hours under stirring;

[0045] (2) After the reaction is completed, cool to room temperature, dilute the reaction mother liquor with 1mL dimethylformamide solution, add it dropwise to 20mL methanol for precipitation, collect the precipitate, and dry to constant weight to obtain polythioamide.

[0046] Diethynyltetraphenylethylene in this example was prepared according to the method disclosed in the literature [Polym.Chem.2012,3,1481].

[0047] The polythioamide of the present embodiment has the structural formula shown in P2:

[0048]

[0049] The reaction equation involved ...

PUM

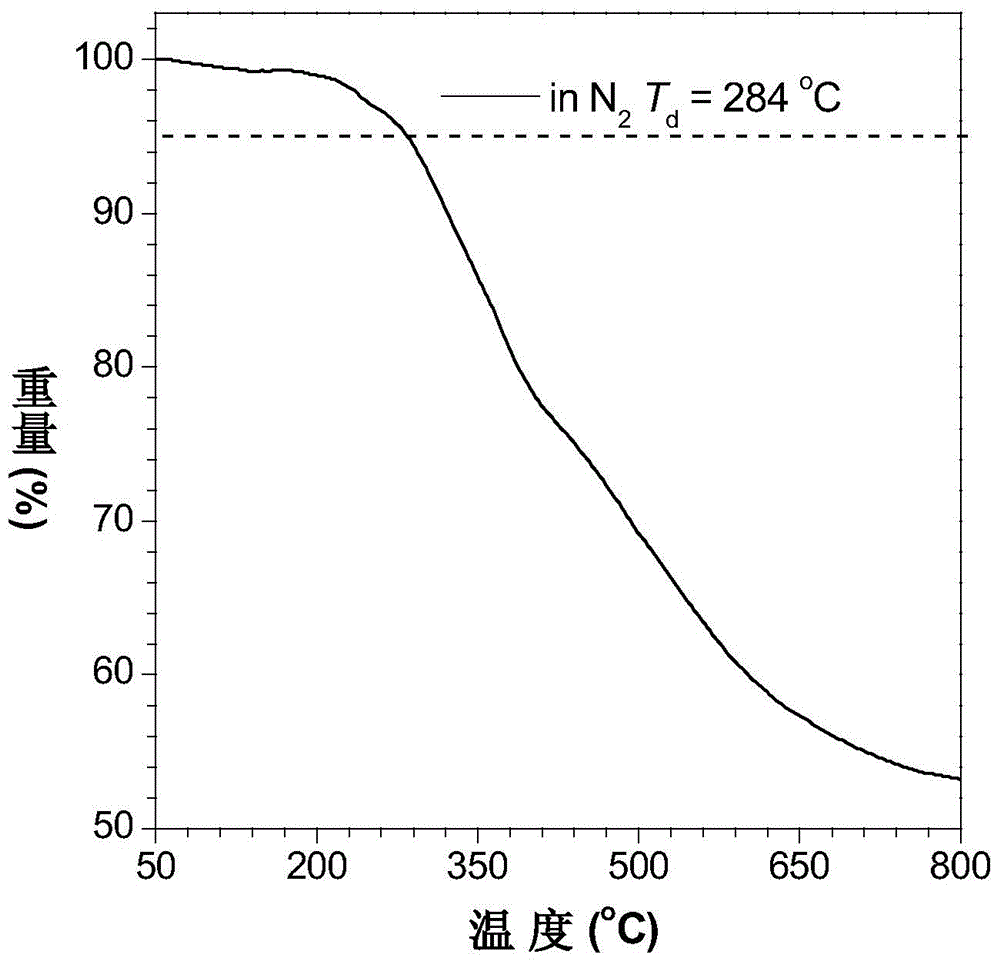

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com