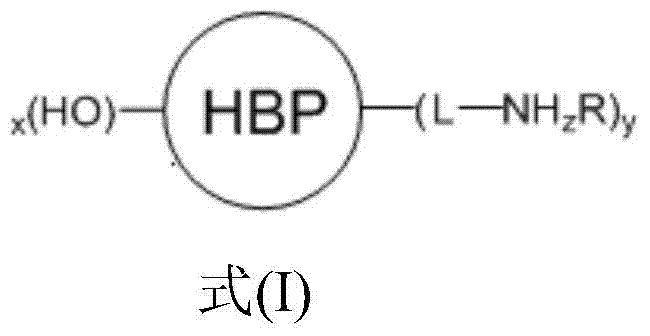

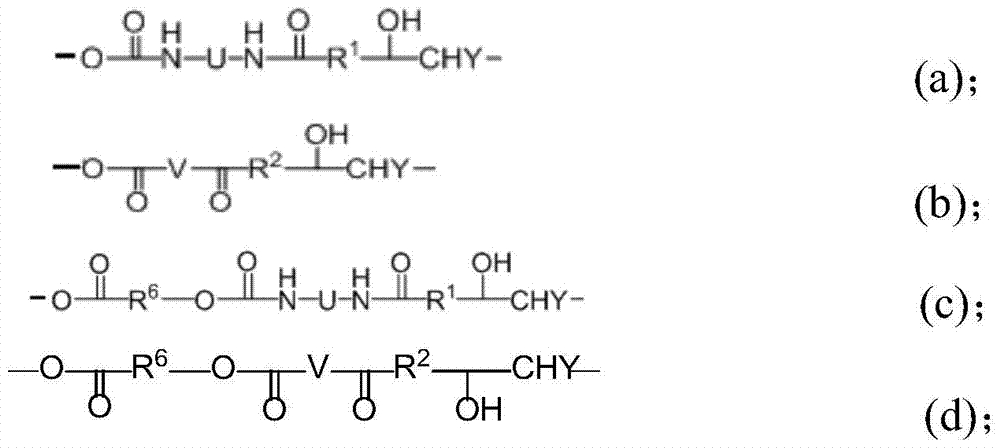

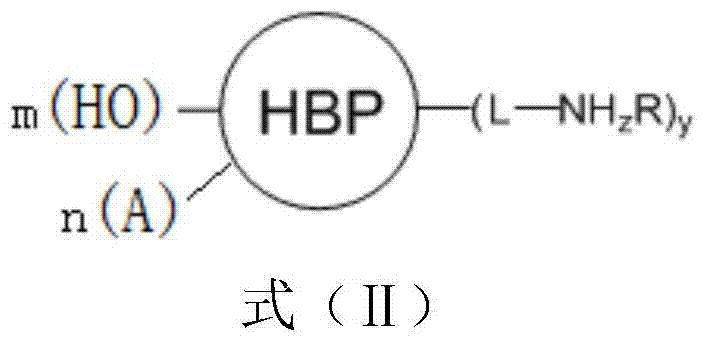

A kind of hyperbranched hydroxyl polymer modified by amines and its application in quick-drying and pigment dispersion system

A technology of hyperbranched hydroxyl and hydroxyl polymer, applied in the direction of pigment slurry, polyester coating, epoxy resin coating, etc., can solve the problem of reducing the functionality of hyperbranched resin, insufficient to reduce hyperbranched hydroxyl polymer, and insufficient pigment dispersion. Effectiveness etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0135]

[0136]

[0137] Synthesis Example

Embodiment 1

[0139] Synthesis of H4001-5% (IPDI-GC), (5% of H4001 hydroxyl is derived by IPDI-GC)

[0140] Synthesis of isophorone diisocyanate-glycidol adduct (IPDI-GC)

[0141] Under room temperature and nitrogen protection, slowly drop 18 grams of glycidol (GC) into 45 grams of isophorone diisocyanate (IPDI), 18 grams of n-butyl acetate and 81 mg of dibutyl tin dilaurate (DBTDL). ) In the mixed solution. After the addition is complete, continue to stir while checking the NCO% every 10 minutes until it reaches the theoretical value of 8.4%.

[0142] Under the condition of 80 degrees and nitrogen protection, 19.3 grams of IPDI-GC mentioned above was slowly added dropwise to 361 grams of H4001. After the addition is complete, continue stirring at 80 degrees for 2 hours until the NCO% is less than 0.1%.

Embodiment 2

[0144] Synthesis of H4001-10% (IPDI-GC), (10% of H4001 hydroxyl is derived by IPDI-GC)

[0145] Under the conditions of 80 degrees and nitrogen protection, 37.5 grams of IPDI-GC (see Example 1) was slowly added dropwise to 350 grams of Boltorn H4001. After the addition is complete, continue to stir at 80 degrees for 3 hours until the NCO% is less than 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com