Ultraviolet shielding type translucent thermal-insulation film preparation method

An external shielding and film technology is applied in the field of preparation of ultraviolet shielding light-transmitting heat-insulating films, which can solve the problems of low infrared reflectivity and shielding rate, poor insulation of heat-insulating materials, and expensive indium-tin materials, etc. Low cost of raw materials, saving use of precious metals, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

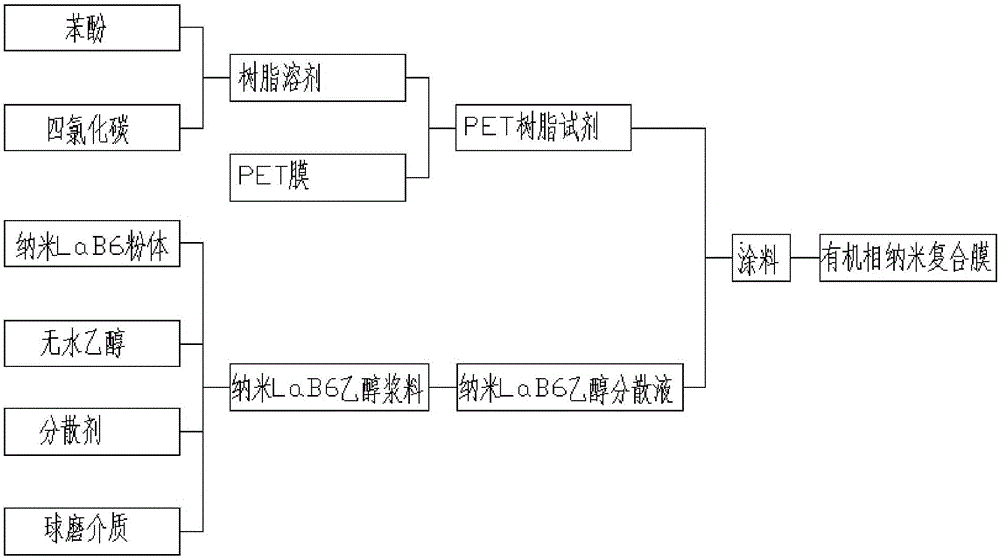

[0035] like figure 1 As shown, a preparation method of an ultraviolet shielding light-transmitting heat-insulating film, which comprises the following steps:

[0036] (1) First, add absolute ethanol and dispersant to the nano-LaB6 powder, and then place it in a ball mill;

[0037] (2) Add ball milling medium to the mixture of nano-LaB6 powder, absolute ethanol and dispersant in the ball mill;

[0038] (3) Ball milling the mixture obtained in step (2) at room temperature in a ball mill for 24 hours to obtain nano-LaB6 ethanol slurry;

[0039] (4) Under the condition of room temperature, the nano-LaB6 ethanol slurry is prepared in a high-speed disperser at 195r / min and the dispersion time is 12 hours to prepare a nano-LaB6 ethanol dispersion liquid, which is for use;

[0040] (5) take phenol and carbon tetrachloride and mix to obtain resin solvent;

[0041] (6) adding a PET film to the above obtained resin solvent, and stirring at a constant temperature of ...

Embodiment 2

[0047] The same as Example 1, the difference is that a method for preparing an ultraviolet shielding light-transmitting heat-insulating film is prepared by using a nano-LaB6 ethanol dispersion with a volume ratio of 3:2 and a PET resin reagent. The nano-LaB6 ethanol dispersion liquid includes absolute ethanol and a dispersant in a volume ratio of 125:1.5, and LaB6 and zirconia balls in a mass ratio of 1:100.

[0048] The preparation method of the ultraviolet shielding light-transmitting heat-insulating film of the present invention has a good absorption capacity for ultraviolet rays with a wavelength of 300-800 nm, and the absorption rate is as high as 55% and the absorption rate is as high as 3750-4000 cm. -1 The mid-infrared light in between has strong reflection performance, the reflectivity is as high as 75%, and the visible light transmittance is as high as 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com