Polypropylene-polyester-carbon nano tube ternary composite alloy and preparation method thereof

A technology of carbon nanotubes and ternary composites, which is applied in the cross field of polymers and nanomaterials, can solve the problems of phase instability, phase domain increase, and low cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] 1) Add 300g of liquid propylene into the reactor, add 0.019mol of triethylaluminum and 0.029mol of methylalumoxane as cocatalysts and 1.0g of bifunctional carbon nanotubes (MgCl 2 / BMMF / TiCl 4 Catalyst system) (in the cocatalyst, the molar ratio between the aluminum element in triethylaluminum and the transition metal element titanium in the catalyst is 50:1; The molar ratio of transition metal element zirconium is 2000:1, the molar ratio between aluminum and transition metal element (titanium+zirconium) in the cocatalyst is 120:1), and 0.2g of hydrogen is introduced, and the pressure is 3.0MPa , the temperature was raised to 70° C., and the reaction was carried out for 0.5 hours to obtain 90.0 g of an intermediate product polymer. The obtained intermediate product (polypropylene / carbon nanotube composite material) was treated with acid alcohol (20% hydrochloric acid) (the volume ratio of hydrochloric acid to ethanol was 1:5). The product was washed with ethanol and d...

Embodiment 2

[0101] Add 1 g of the acid-alcohol-treated intermediate product obtained in Example 1 and 10 ml of toluene into a 100 ml dry flask equipped with a magnet, and pump and dry in an oil bath at 50° C. for 4 hours. Warming up to 80°C, stirring at 80°C for 4h. The temperature was raised to 130° C., 0.03 ml of stannous octoate was added, and 30 ml of caprolactone monomer started to react, and the stirring reaction was continued for 24 hours. The product was washed 4 times with excess tetrahydrofuran and filtered using a Φ0.22 μm polytetrafluoroethylene membrane until the filtrate was poured into ice methanol and no precipitation appeared, then washed with distilled water and ethanol in turn, filtered, and dried at 40°C until constant Weight, finally obtained polypropylene-polycaprolactone-carbon nanotube ternary alloy 1.2g.

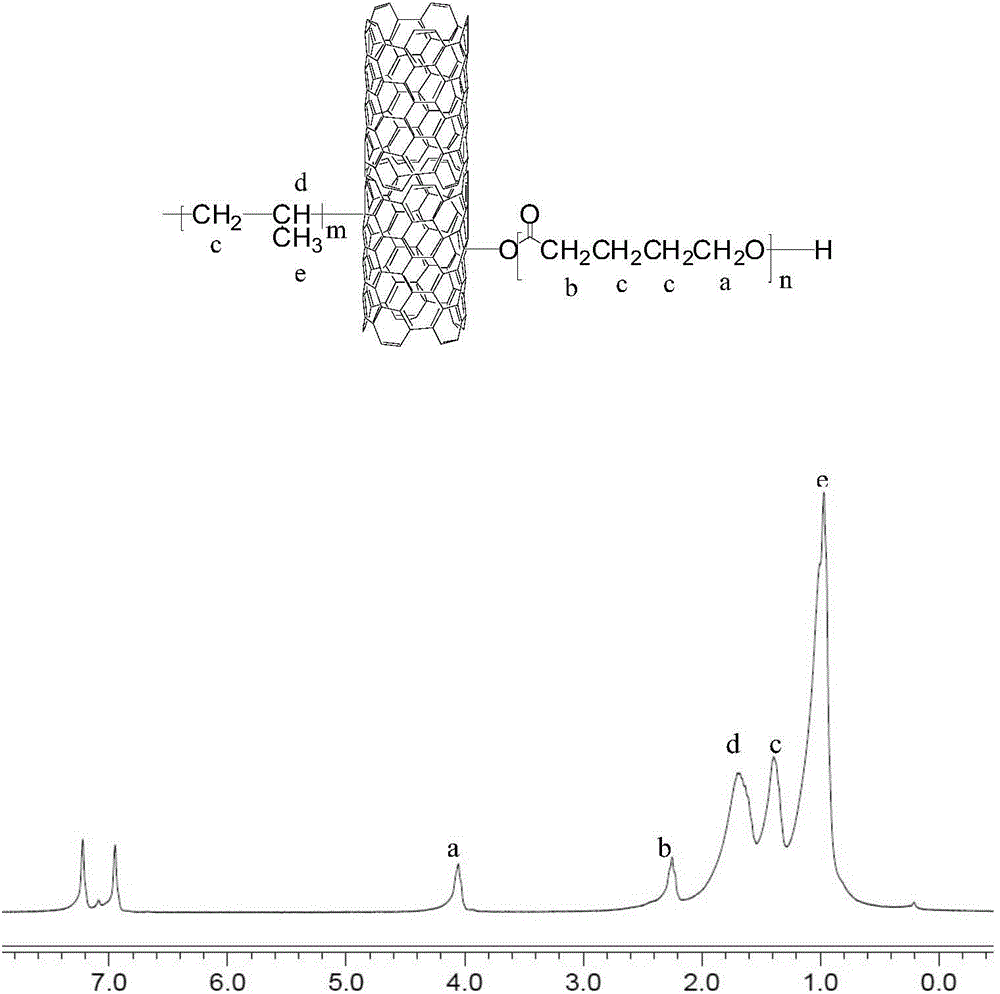

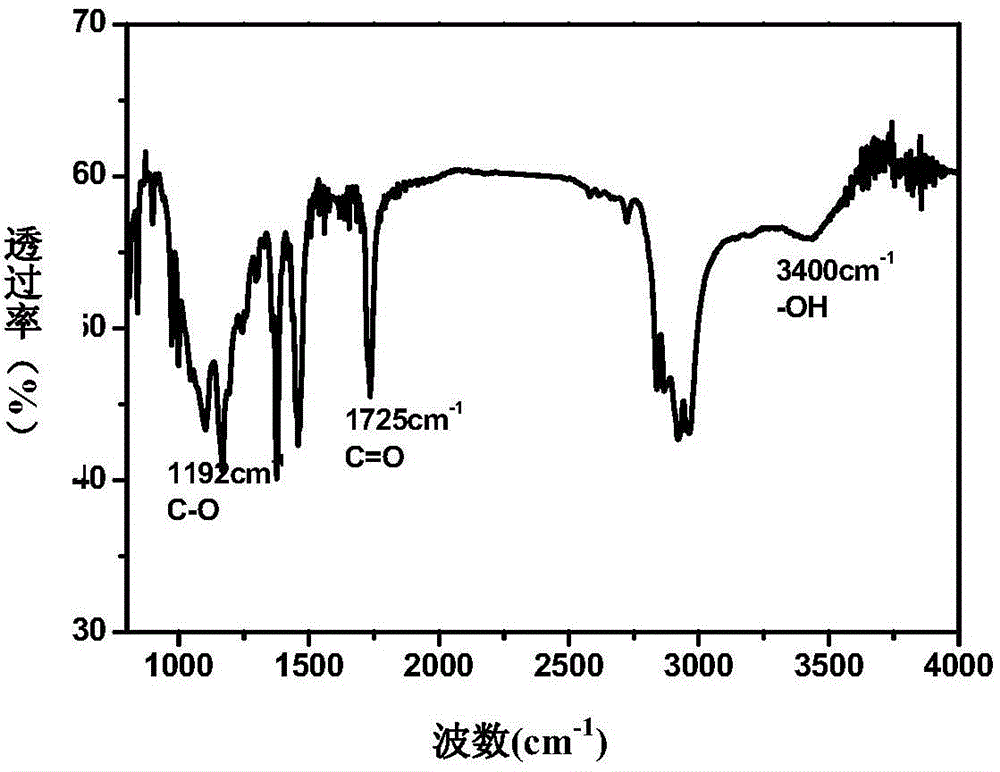

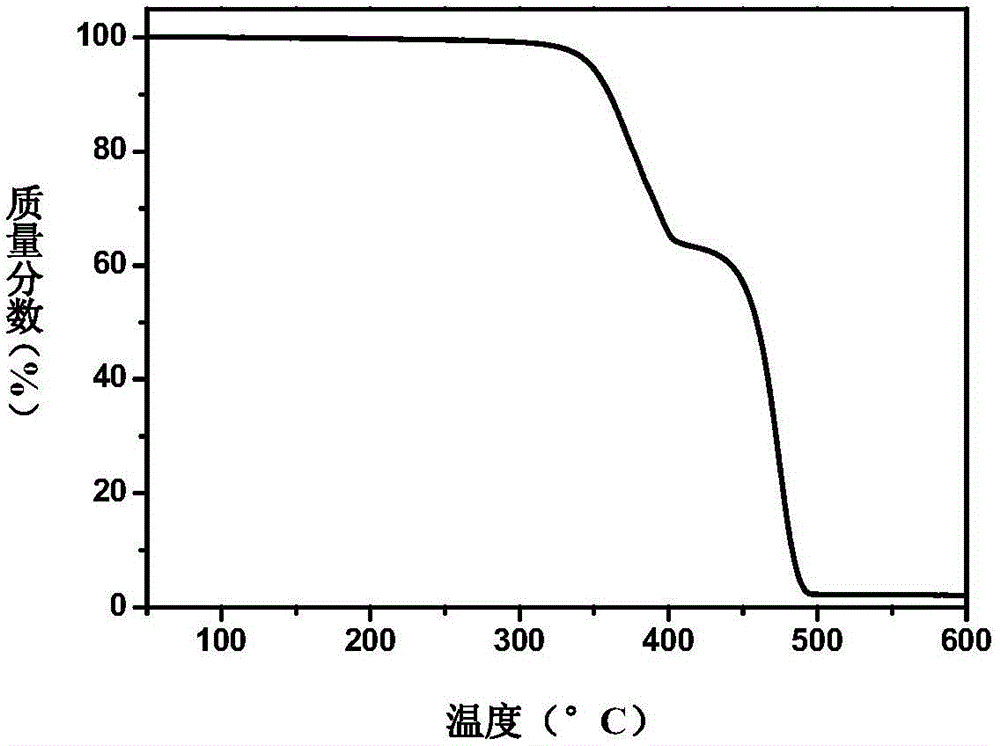

[0102] The polypropylene-polycaprolactone-carbon nanotube ternary alloy is composed of carbon nanotubes, homopolymerized polypropylene resin and homopolymerize...

Embodiment 3

[0104] Add 1 g of the acid-alcohol-treated intermediate product obtained in Example 1 and 10 ml of toluene into a 250 ml dry flask equipped with a magnet, and pump and dry in an oil bath at 50° C. for 4 hours. Raise the temperature to 80°C and stir at 80°C for 4h. The temperature was raised to 130° C., 1.0 ml of stannous octoate was added, and 100 ml of caprolactone monomer started to react, and the stirring reaction was continued for 24 hours. The product was washed 4 times with excess tetrahydrofuran and filtered using a Φ0.22 μm polytetrafluoroethylene membrane until the filtrate was poured into ice methanol and no precipitation appeared, then washed with distilled water and ethanol in turn, filtered, and dried at 40°C until constant Weight, finally obtained polypropylene-polycaprolactone-carbon nanotube ternary alloy 1.3g.

[0105] The polypropylene-polycaprolactone-carbon nanotube ternary alloy is composed of carbon nanotubes, homopolymerized polypropylene resin and homo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com