Low-cost and highly-conductive nano-carbon material preparation method

A nano-carbon material, high-conductivity technology, applied in nano-technology, fibrous fillers, carbon-silicon compound conductors, etc., can solve problems such as low continuous load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

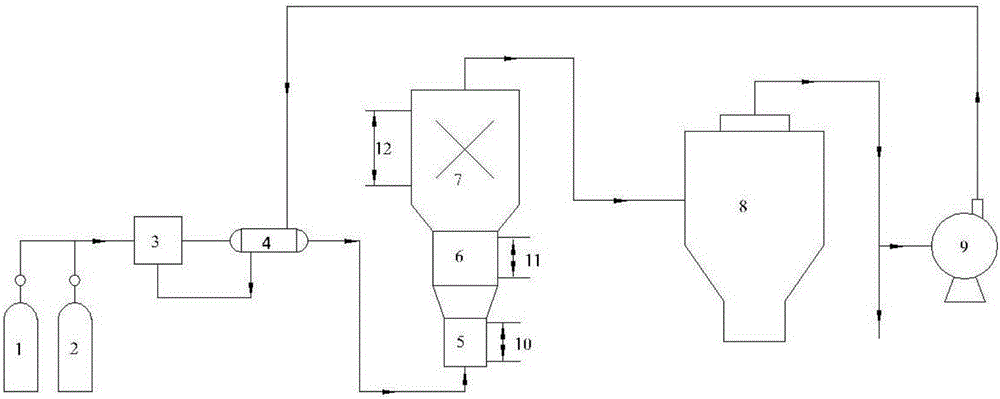

[0017] Example 1: A method for producing nano-carbon materials using methane as a raw material, using argon as a carrier gas, adding methane to the carrier gas, AC discharge voltage at 20 KV, current at 0.1 A, and discharge gap of 20 mm; DC discharge The voltage is 560 V, the current is 1-25 A, the volume ratio of methane to argon is 1:2, the residence time of the gas in the plasma generator is 0.01 seconds, and then enters an insulated fluidized bed reactor; then The product and tail gas are separated by a cyclone separator, and then the tail gas is used for circulation. The mixed gas of methane and argon is preheated first, and then enters the plasma generating device together with the mixed gas, so that nano-carbon materials are prepared in this way, and the reaction See attached for the process figure 1 shown. In the test, it was measured by using a high-temperature radiometer. Under the above-mentioned working conditions, the temperature of the reactor is about 1000-1800...

Embodiment 2

[0018] Embodiment 2: A method for producing nano-carbon materials using acetylene as a raw material, using nitrogen as a carrier gas, adding acetylene to the carrier gas, AC discharge voltage at 20 KV, current at 0.1 A, and discharge gap of 20 mm; DC discharge voltage The current is 560 V, the current is 1-25 A, the volume ratio of acetylene to argon is 1:4, the residence time of the gas in the plasma generator is 0.03 seconds, and then enters an insulated fluidized bed reactor; then passes through The cyclone separator separates the product and the tail gas, and then the tail gas is used for circulation. The mixed gas of methane and argon is preheated first, and then enters the plasma generating device together with the mixed gas, so that nano-carbon materials are prepared in this way. The reaction process See attached figure 1 shown. In the test, it was measured by using a high-temperature radiometer. Under the above-mentioned working conditions, the temperature of the reac...

Embodiment 3

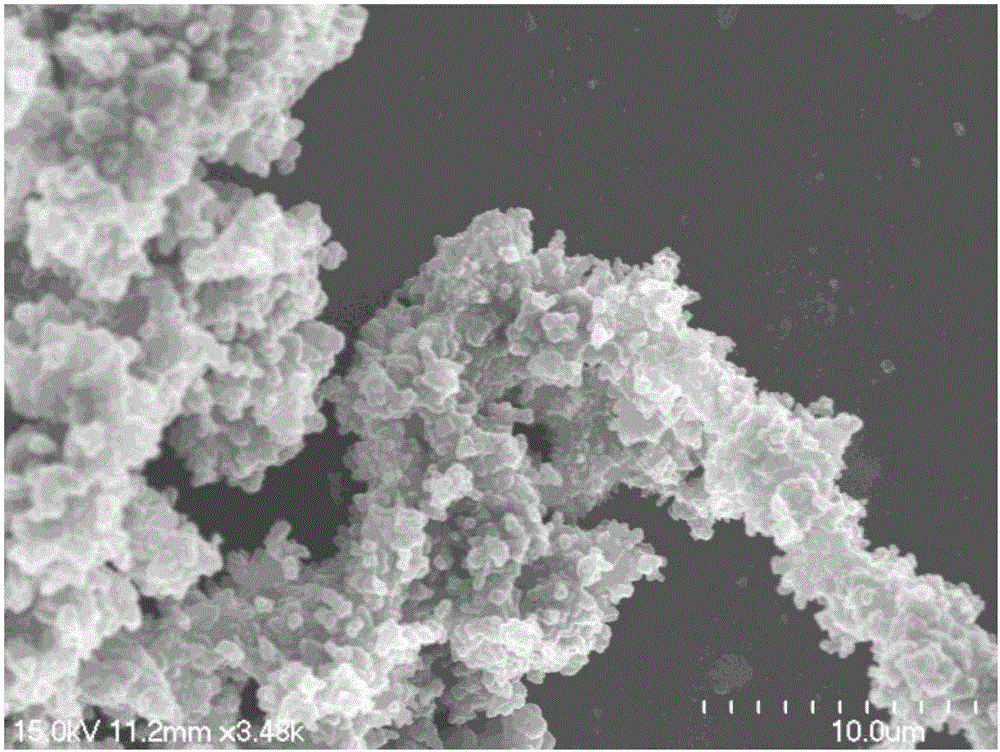

[0019] Example 3: A method for producing nano-carbon materials using propane as a raw material, using argon as a carrier gas, adding propane to the carrier gas, and adopting an AC-DC combined discharge mode, with an AC discharge voltage of 20 KV and a current of 0.1 A. The gap is 20 mm; the DC discharge voltage is 560 V, and the current is 1-25 A. The volume ratio of propane to argon is 1:3, the residence time of the gas in the plasma generator is 0.01 seconds and then enters the insulated fluidized bed reactor, and then the gas-solid mixture is separated from the product by a cyclone separator, and the tail gas is pre- The hot unreacted mixed gas is then mixed together and then enters the plasma generator for cyclic cracking. The reaction flow chart is attached figure 1 shown. Prepared SEM as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com