Silver alloy wire

A silver alloy and wire technology, applied in the direction of metal layered products, electrical components, circuits, etc., can solve the problems of increasing the operating cost of the wire bonding manufacturing method, increasing the risk of the manufacturing method, and easy oxidation of the silver alloy wire, etc., to achieve Improved wire drawing workability and ball stability, reduced number of heterogeneous nucleation, and excellent wire drawing workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 18、 comparative example 2 to 19

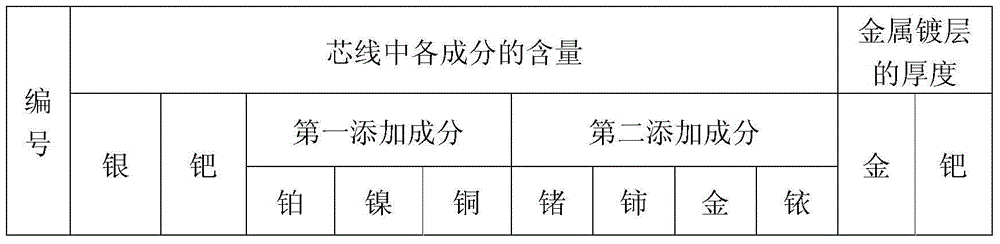

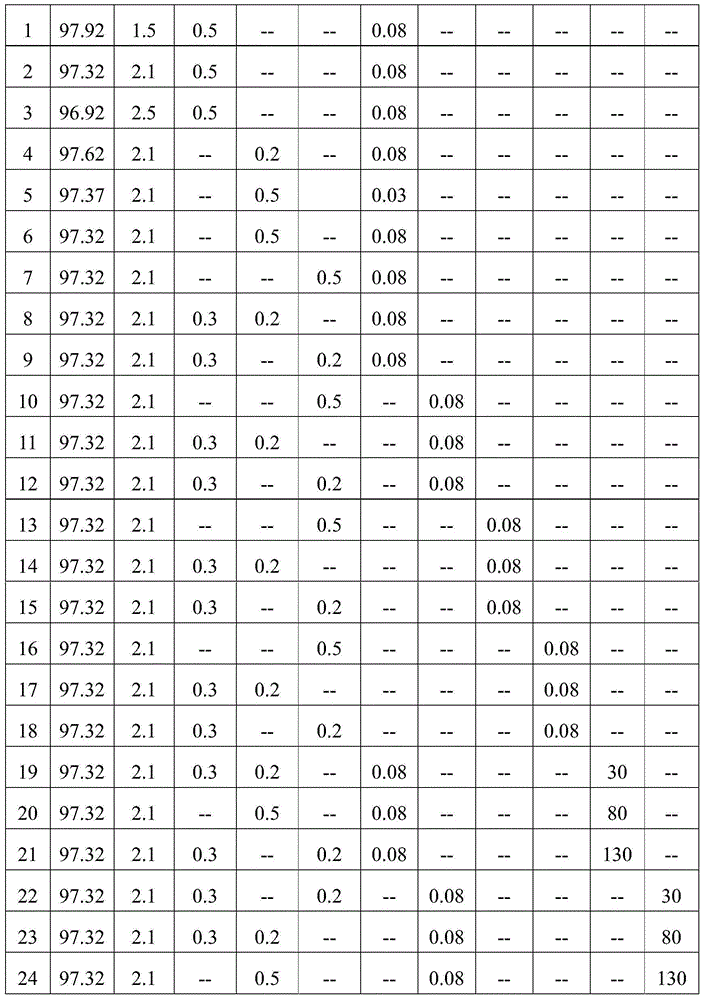

[0030] Examples 1 to 18, Comparative Examples 2 to 19: Silver alloy wire rod

[0031] First, according to the mixing ratio shown in Table 1 and Table 2 below, mix raw materials such as silver, palladium, the first added component and the second added component, and cast the mixed raw materials to form a wire with a diameter of 8 to 10 mm. silver alloy bus bars.

[0032] Then, the silver alloy bus bar is subjected to continuous and several times of rough drawing manufacturing method, thus the wire diameter of the silver alloy bus bar is reduced from 8 to 10 mm to about 1 mm; And several times of the drawing wire manufacturing method, thus the wire diameter of the silver alloy bus bar through the drawing wire is reduced from 1 millimeter to 200 to 300 microns, so that the wire diameter cross-sectional area of the silver alloy bus bar through the drawing wire is compared to that without The silver alloy bus bar before the thick and medium wire manufacturing method is reduced b...

Embodiment 19 to 21

[0041] Examples 19 to 21: Silver alloy wire

[0042] The silver alloy wires of Examples 19 to 21 are substantially prepared by the same method as the aforementioned silver alloy wires of Examples 1 to 18.

[0043] The difference is that, after the aforementioned thick and medium drawn wire manufacturing methods and the first annealing heat treatment, the semi-finished product is subjected to continuous and several times of thin drawn wire manufacturing method and ultra-fine drawn wire manufacturing method, and supplemented by 500 to A second annealing heat treatment is performed on it at a temperature of 700° C. to obtain a core wire.

[0044] Finally, the gold-plated manufacturing method is performed on the core wire, that is, the production of the silver alloy wire rods in Examples 19 to 21 is completed.

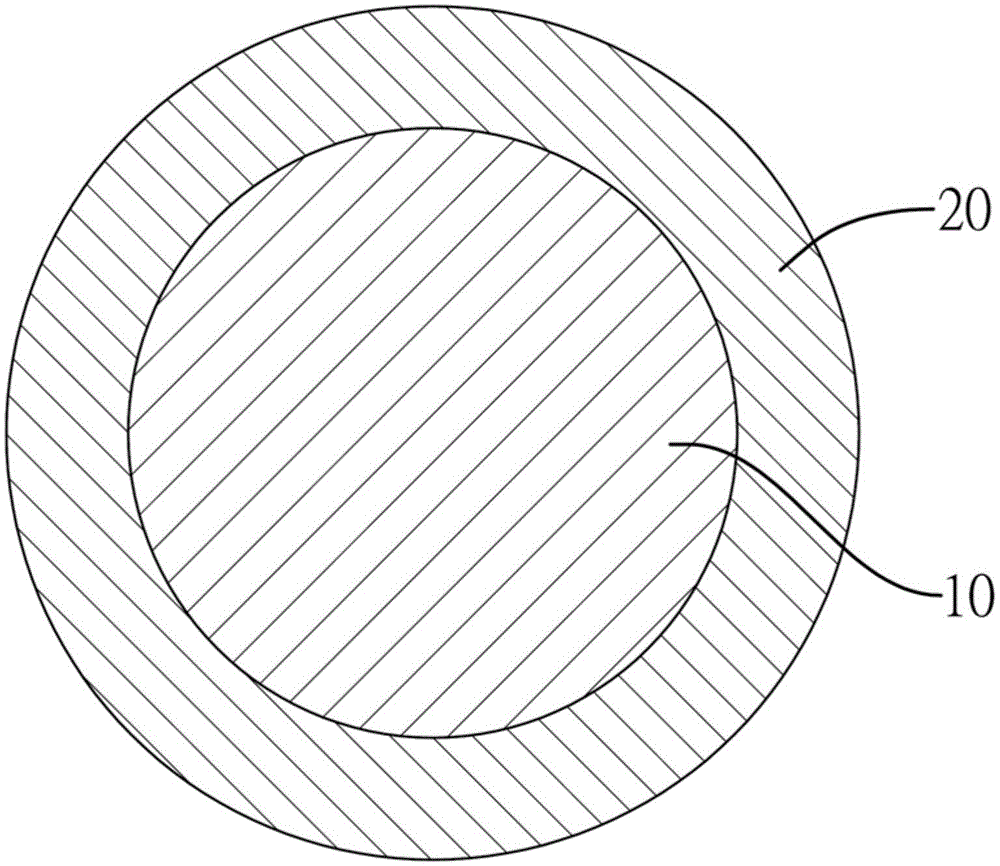

[0045] see figure 1 As shown, the silver alloy wires (finished products) of Examples 19 to 21 include a core wire 10 and a metal coating 20 formed on the outer surface o...

Embodiment 22 to 24

[0046] Examples 22 to 24: Silver alloy wire

[0047] The silver alloy wires of Examples 22 to 24 are also substantially prepared by the method for producing the silver alloy wires of Examples 1 to 18 above.

[0048] The difference is that, after the aforementioned thick and medium drawn wire manufacturing methods and the first annealing heat treatment, the semi-finished product is subjected to continuous and several times of thin drawn wire manufacturing method and ultra-fine drawn wire manufacturing method, and supplemented by 500 to A second annealing heat treatment is performed on it at a temperature of 700° C. to obtain a core wire.

[0049] Finally, the palladium-plated manufacturing method is performed on the core wire, that is, the production of finished silver alloy wire rods in Examples 22 to 24 is completed.

[0050] In Examples 22 to 24, the structure of the silver alloy wire (finished product) is also as figure 1 As shown, that is, the silver alloy wire also incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com