Method for preparing GaMnN diluted magnetic semiconductor thin film material

A technology of dilute magnetic semiconductor and thin film materials, applied in the application of magnetic film to substrate, metal material coating process, gaseous chemical plating, etc., can solve the problems of complex tail gas treatment process, expensive raw materials, high maintenance cost, etc. Achieve the effects of short production cycle, good crystal quality and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

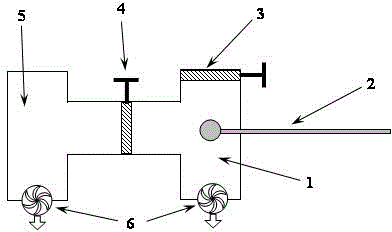

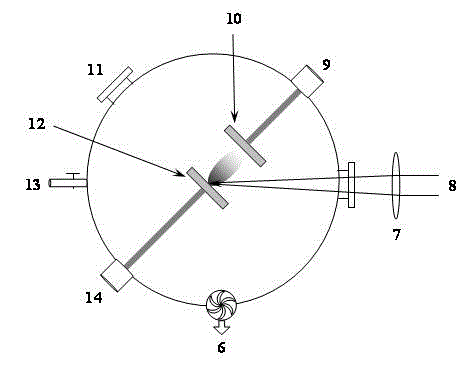

[0020] Please also see figure 1 with figure 2 , the technical features of the present invention will be further described below in conjunction with specific growth processes.

[0021] (1) Before preparing the GaMnN dilute magnetic semiconductor thin film material, the substrate was ultrasonically cleaned twice with acetone, each time for 10 minutes, after each cleaning, it was rinsed with deionized water for about 2 minutes, and then ultrasonically cleaned with ethanol for 10 minutes , and finally rinsed with deionized water and dried for later use.

[0022] (2) Put the GaN ceramic target on the transfer rod 2 through the valve 3 of the sampling chamber 1 . Turn on the mechanical pump of the vacuum system 6, and when the pressure in the growth chamber 5 reaches below 10 Pa, turn on the molecular pump of the vacuum system 6, pump for about 4 hours, and the background vacuum of the system can reach 5×10 -5 Below Pa. Then, the GaN ceramic target is put into a target positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com