Loudspeaker diaphragm preparation method

A loudspeaker and film technology, which is applied in the field of loudspeaker diaphragm preparation, can solve the problems of many diaphragm layers, poor diaphragm firmness, and affecting the stability of the diaphragm, and achieve light wear resistance, strong toughness, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

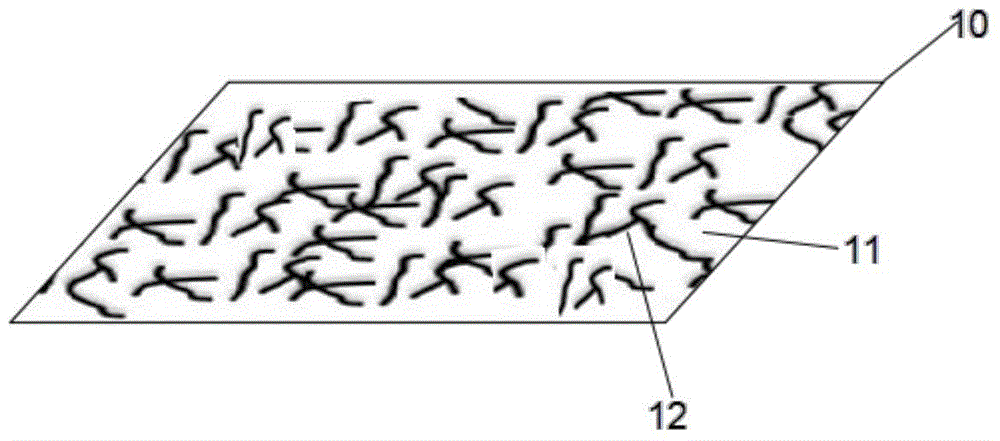

[0023] A preparation method for a loudspeaker diaphragm, wherein the high molecular polymer 11 is used as a base material to form a graphene high molecular polymer hybrid material film 10 by doping a graphene material 12 through an in-situ polymerization method, and its manufacturing steps include the following:

[0024] S1, the graphene material is dispersed in ethylene glycol by ultrasonic method to form a graphene material / ethylene glycol mixed solution.

[0025] S2, add the graphene material / ethylene glycol mixed solution in S1 to the raw material for synthesizing high molecular polymers, mechanically stir to form a slurry, and form a high molecular polymer slurry mixed with graphene through esterification reaction, which is cooled and solidified into Graphene polymer hybrid material film.

Embodiment 2

[0027] A preparation method for a loudspeaker diaphragm, wherein the high molecular polymer 11 is used as a base material to dope a graphene material 12 through a solution mixing method to form a graphene high molecular polymer mixed material film 10, and its manufacturing steps include the following steps: The steps include the following:

[0028] S1, disperse graphene material in ethylene glycol by ultrasonic method to form graphene material / ethylene glycol mixed solution; disperse high molecular polymer in toluene solution by ultrasonic method to form high molecular polymer / toluene mixed slurry .

[0029] S2, in the case of rapid stirring, add the graphene material / ethylene glycol mixed solution in the high molecular polymer / toluene mixed slurry, make the graphene material completely dispersed in the high molecular polymer / toluene mixed slurry, cool and solidify into Graphene polymer hybrid material film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com